Impact type water bucket fine welding sectioning method and structure

An impact type and bucket technology, which is applied in the field of fine welding split method and structure of impact type bucket, can solve the problems of large alternating stress amplitude of impact type runner, broken bucket of casting bucket and fatigue damage, etc. The effect of reducing production difficulty, improving strength and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

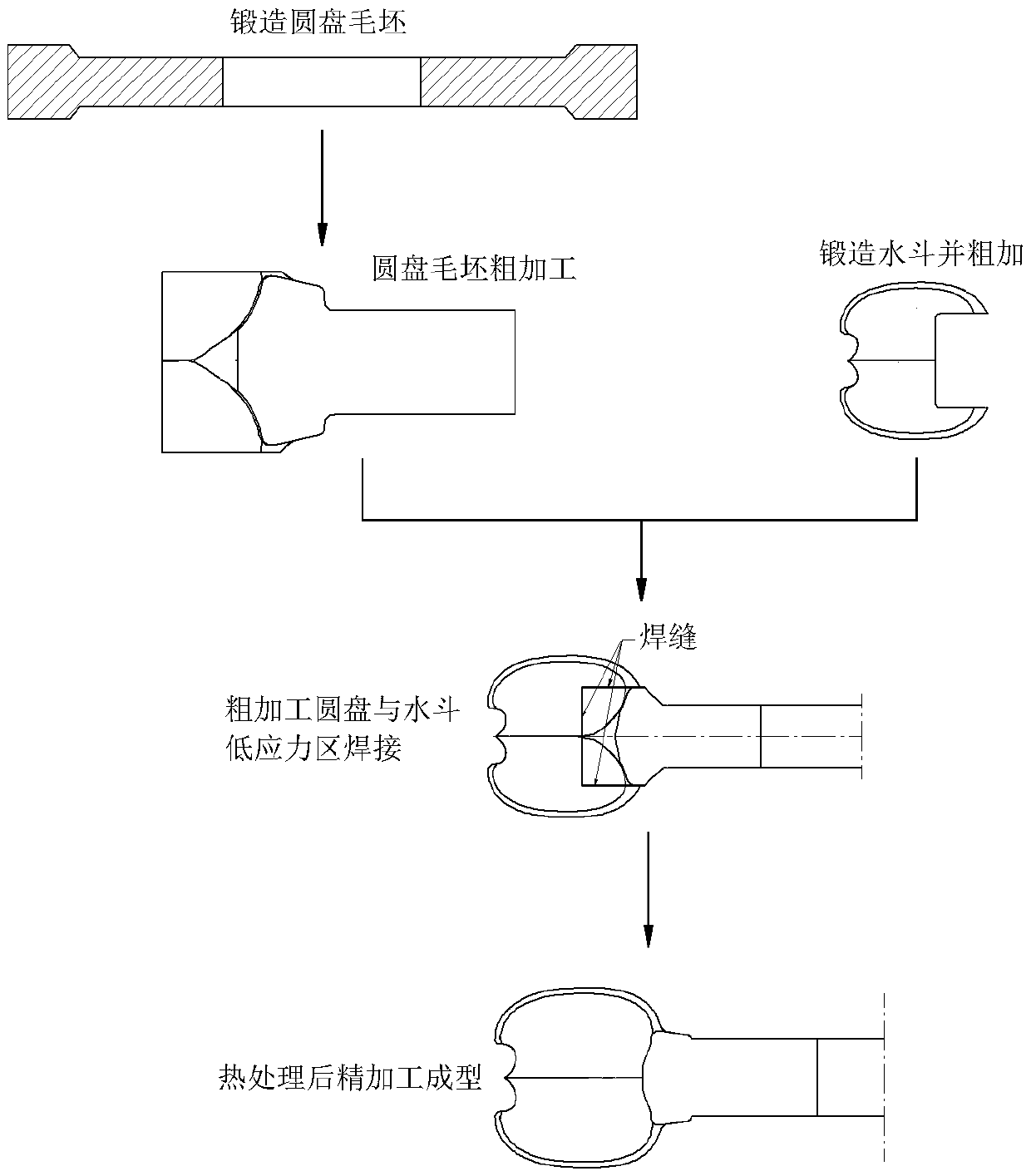

Method used

Image

Examples

Embodiment 1

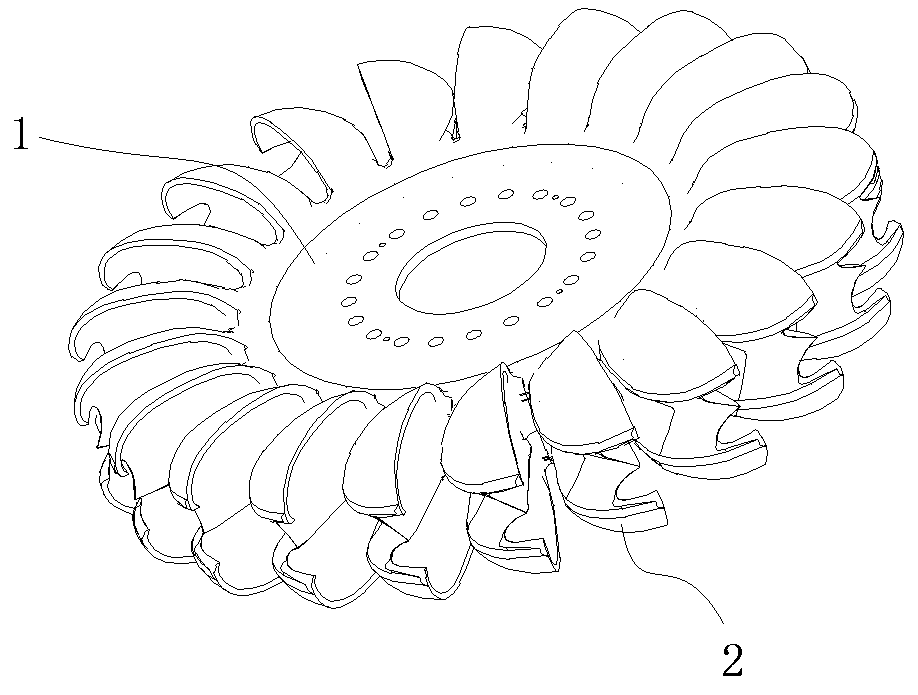

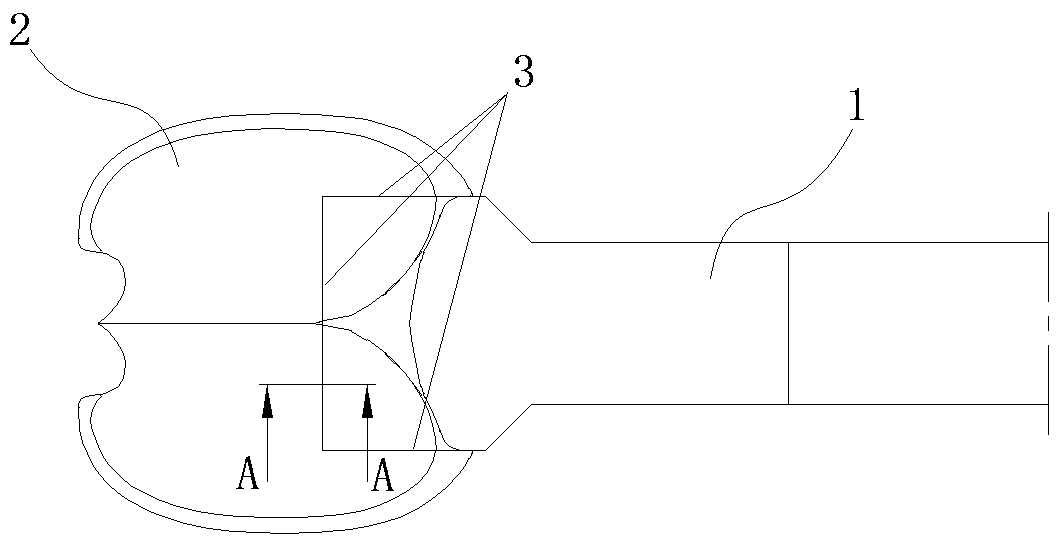

[0041] An impact type water bucket precision welding split structure, such as figure 2 As shown, it includes a disk 1 and several water buckets 2 which are independently provided with the disk 1 , and the water buckets 2 are arranged equiangularly around the outer circumference of the disk 1 . like image 3 As shown, the outer circumference of the disc 1 is provided with a disc welding part 1a corresponding to each bucket 2, the disc welding part 1a protrudes from the outer circumference of the disc 1, and the inner side of the water bucket 2 is provided with a disc welding part 1a The matching bucket welding portion 2a, the inner side of the bucket 2 is welded and fixed to the disk welding portion 1a on the outer periphery of the disk 1 through the bucket welding portion 2a.

[0042] like Figure 4 As shown, an arc-shaped end welding surface 12 is provided on the outer side of the disc welding part 1a, and parallel side welding surfaces 11 are respectively provided on both...

Embodiment 2

[0044] The difference between embodiment 2 and embodiment 1 is that, as Figure 8 As shown, the outer side of the disc welding part 1a is provided with a disc welding plane 101, such as Figure 9 As shown, the water bucket welding part 2a is provided with a water bucket welding plane 201 matched with the disc welding plane 101, the water bucket 2 is provided with an inward depression, and the depression of the water bucket 2 is arc-shaped, and the water bucket welding plane 201 is located at the bottom of the water bucket. At the bottom of the depression of bucket 2, the structure after the two are welded is as follows Figure 10 As shown, the weld 3 is a straight line or close to a straight line, and the weld between the water bucket 2 and the disc 1 is close to the bottom of the depression of the water bucket 2, which effectively reduces the amount of welding and ensures welding economy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com