Forge welding technological method for large circle-shaped thin wall structure parts

A technology of thin-walled structure and process method, which is applied in the direction of furnace type, manufacturing tools, welding equipment, etc., and can solve the problems of material waste and expensive manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

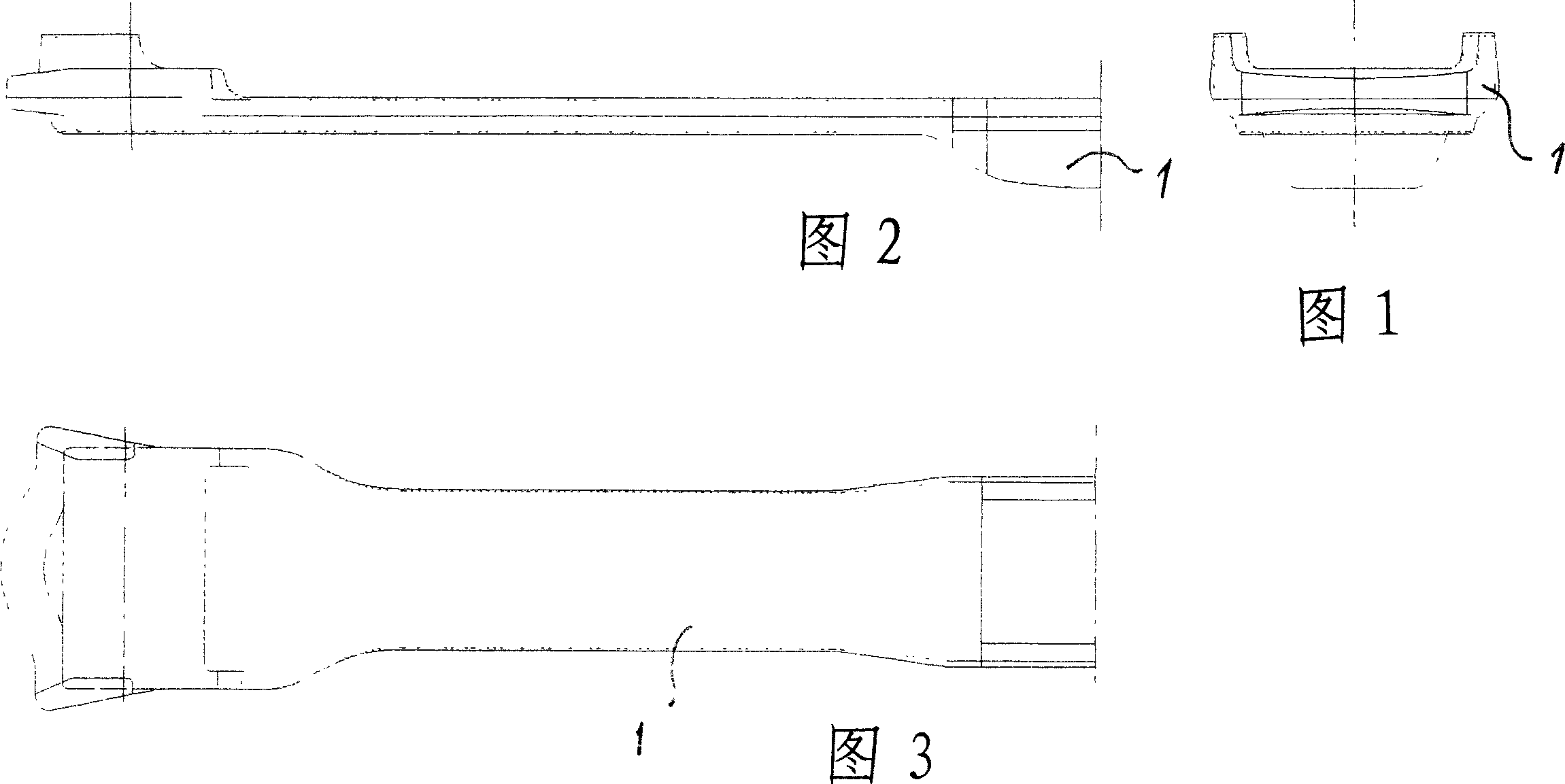

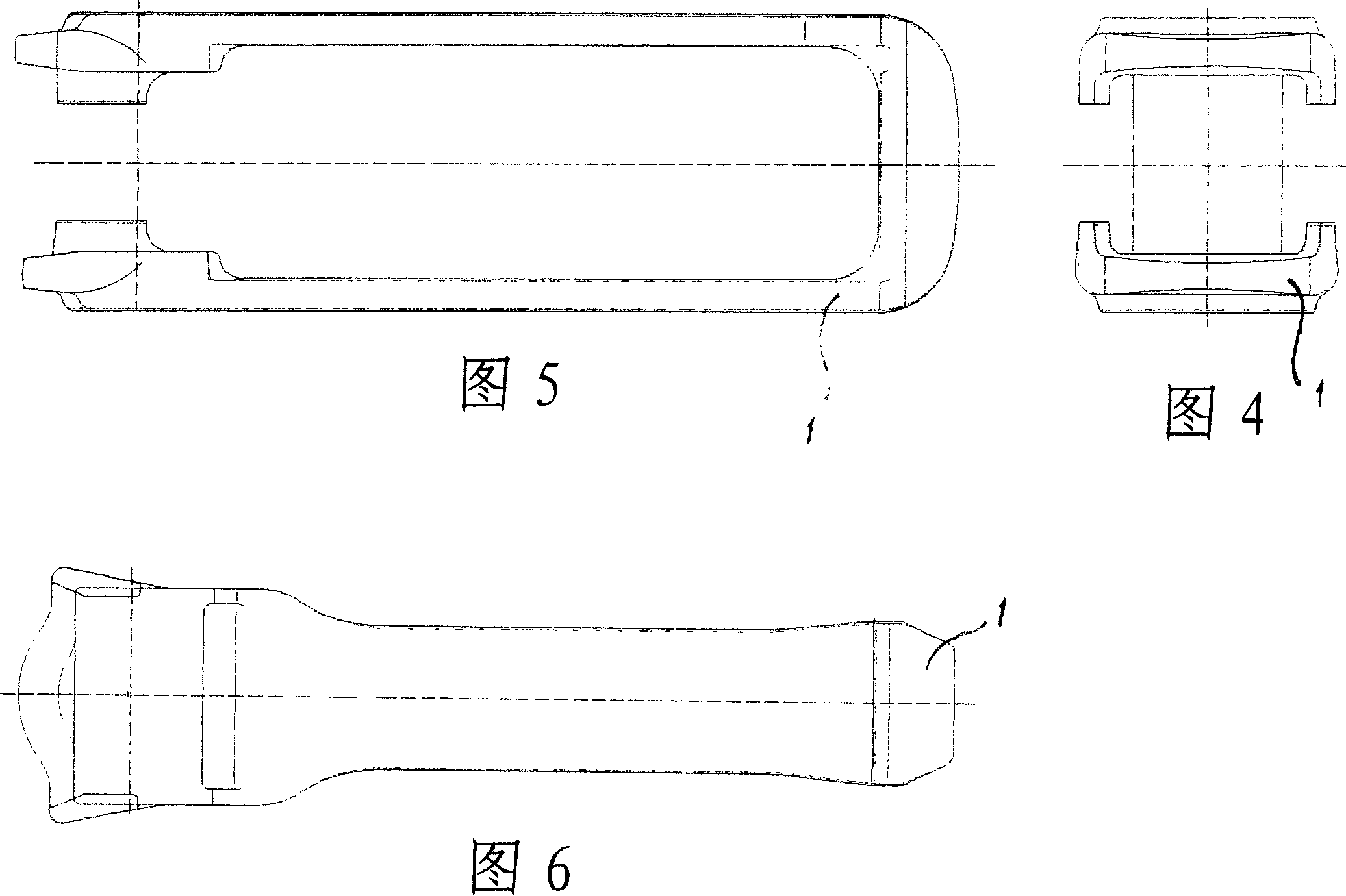

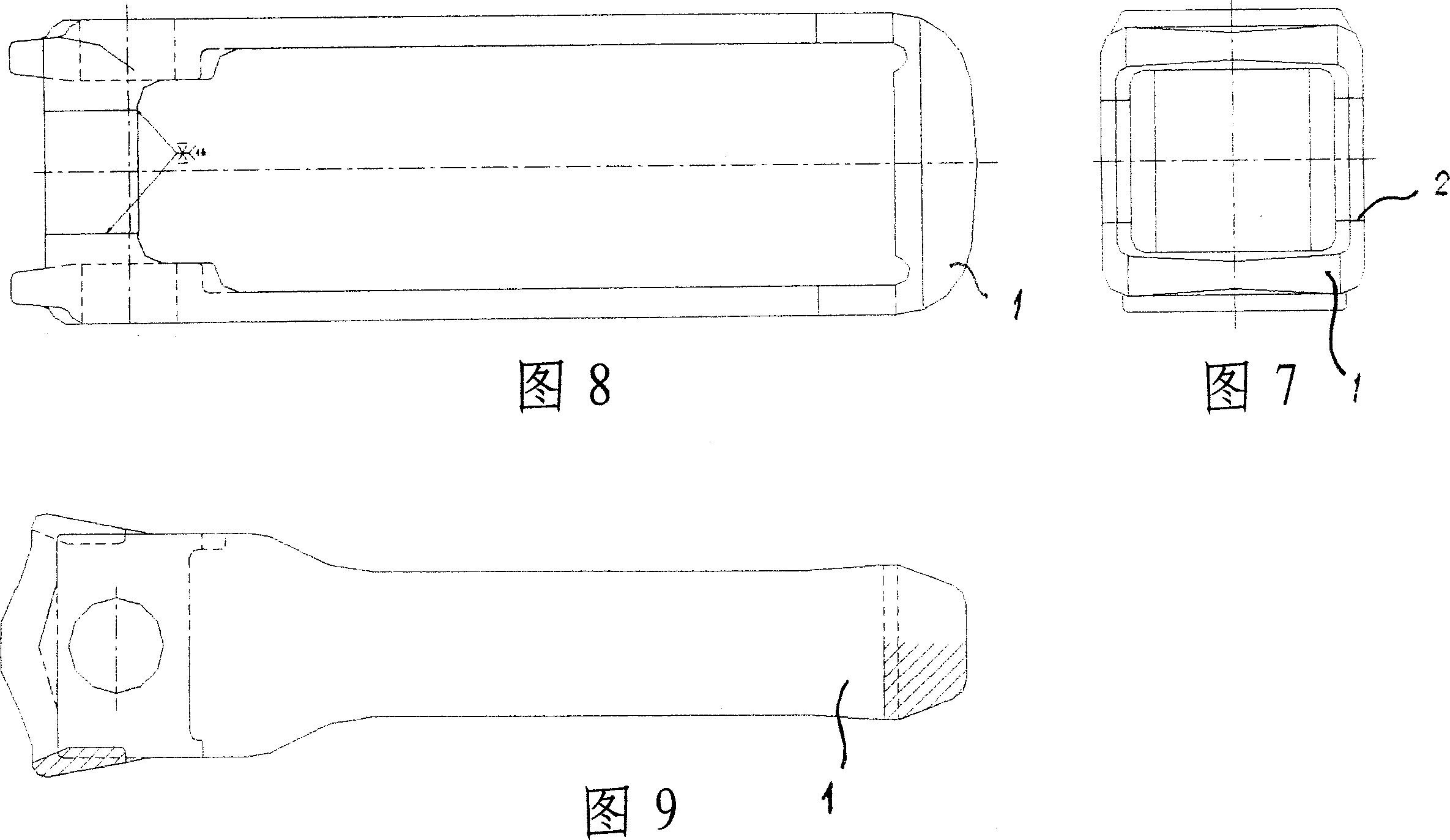

[0027] See Figure 1, Figure 2, Figure 3, Figure 4, Figure 5, Figure 6, Figure 7, Figure 8 and Figure 9.

[0028] A large back-shaped thin-walled structural part, a coupler frame part of a railway freight car, the size of which is 932.5×291×260mm, the hollow size is 740.5×235mm, the thickness of the wall is 28mm, and the height of the edge is 260mm. The so-called large-scale back-shaped thin-walled structural parts are manufactured by forging and welding process. The first step: forging billets, forging according to the product size difference, heating temperature ≤ 1200 ° C, final forging temperature ≥ 800 ° C, billet making equipment 1.5t electro-hydraulic hammer is used; the second step: die forging, heating temperature ≤ 1200 ℃, final forging temperature ≥ 800 ℃, the total projected area of precision billet is 2932cm 2 , the size of the front and back of the worktable is 2400mm, and the equipment adopts a 4000t screw press, with 3 strikes; the third step: simmering and be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com