Pressure containing heat transfer tube and method of making thereof

a technology of heat exchanger and pressure-containing tube, which is applied in the direction of indirect heat exchanger, laminated elements, light and heating apparatus, etc., can solve the problems of increasing the cost of brazing process, reducing the efficiency of heat exchanger, and increasing the cost of raw materials and additional manufacturing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

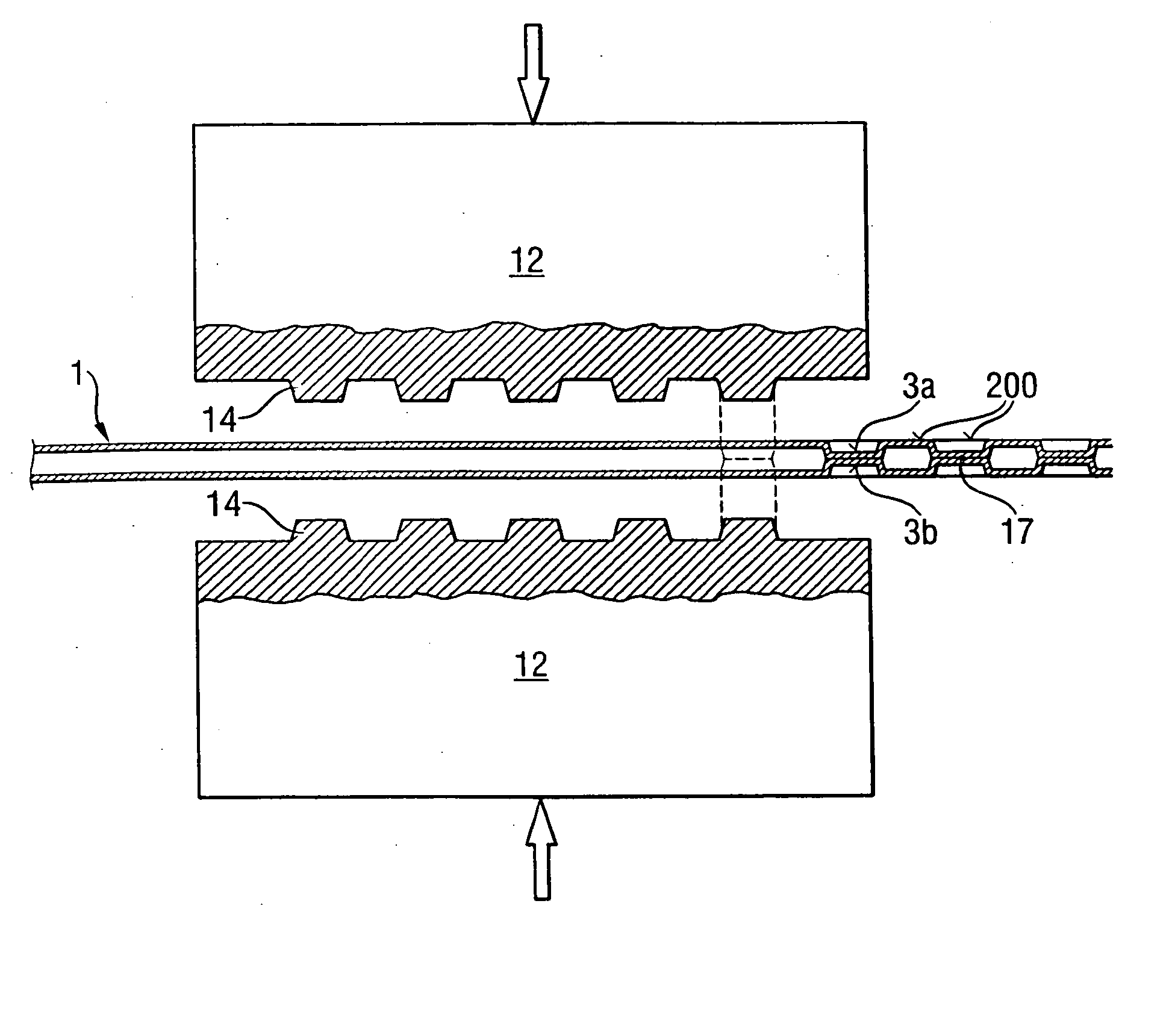

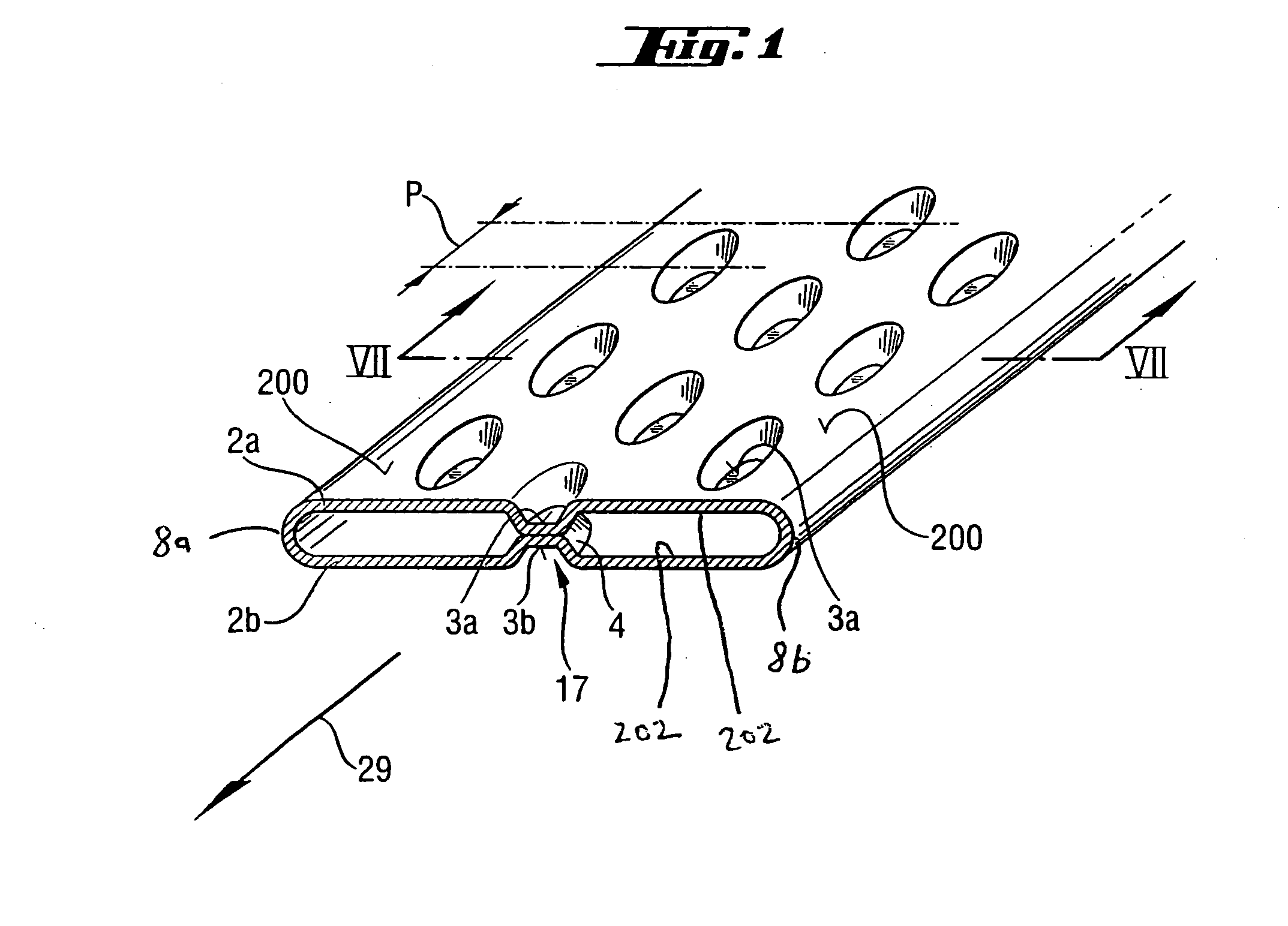

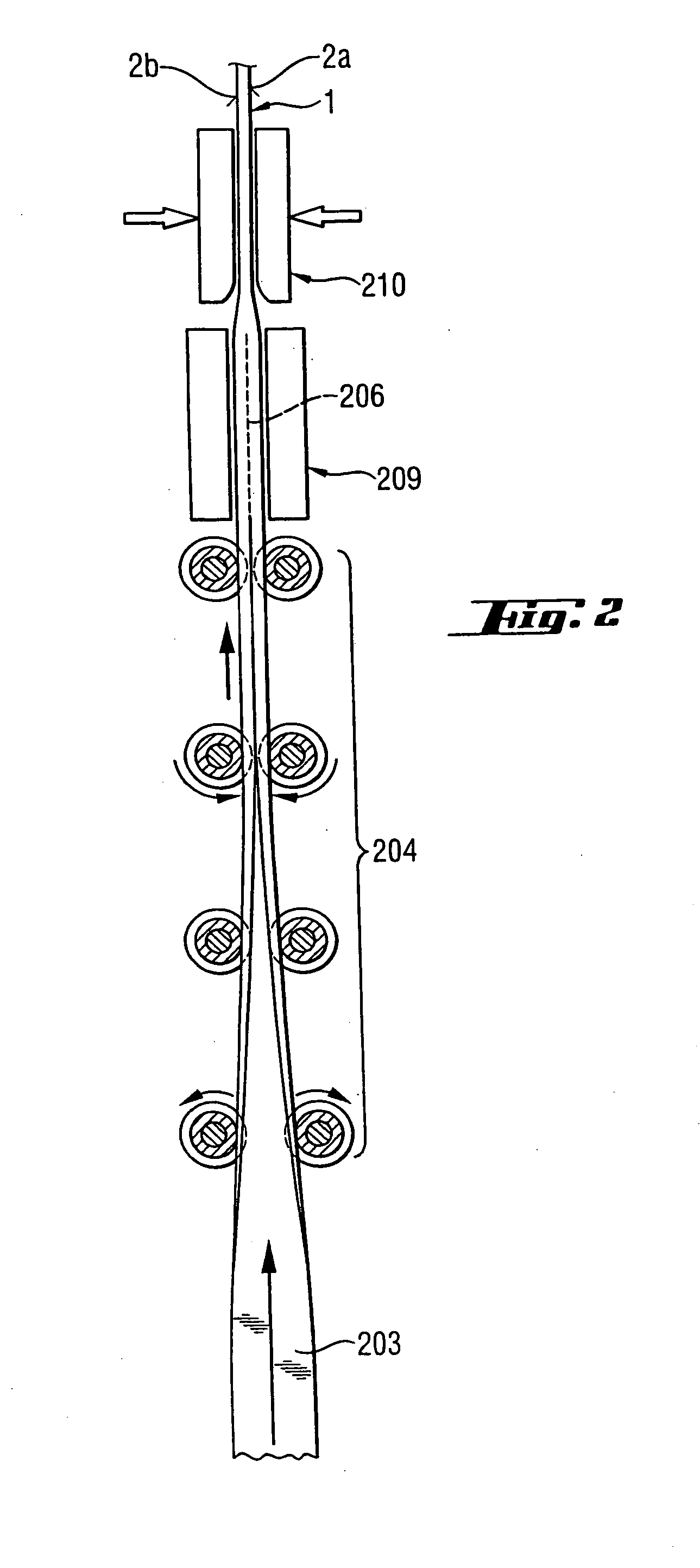

[0024] In FIG. 1, a tube 1 has major outer surfaces 200 formed on the outside of opposed walls 2a and 2b. Walls 2a and 2b are connected by curved end walls 8a and 8b. Walls 2a and 2b also have inner surfaces 202. The tube 1 may be constructed out of copper or other suitable materials. The tube 1 may be formed by several methods as will be evident to those of ordinary skill in the art. For example as shown in FIG. 2, tube 1 may be formed by taking flat stock 203 and roll forming it by turning up the edges gradually and then welding a seam 206 to join the edges. The seam is welded in a continuous process by an apparatus 209. Apparatus for continuous welding of tubes are generally known and therefore will not be described in detail herein. If the tube 1 is initially formed with a round profile, the tube may then be flattened by a press to form a flat tube having opposed walls 2a and 2b. Alternatively, the tube may be formed into a flat tube configuration and welded to shape. Also, othe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com