Ganged scanning of multiple magnetrons, especially two level folded magnetrons

A magnetron and linkage technology, applied in the field of magnetron, can solve problems such as incomplete target utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

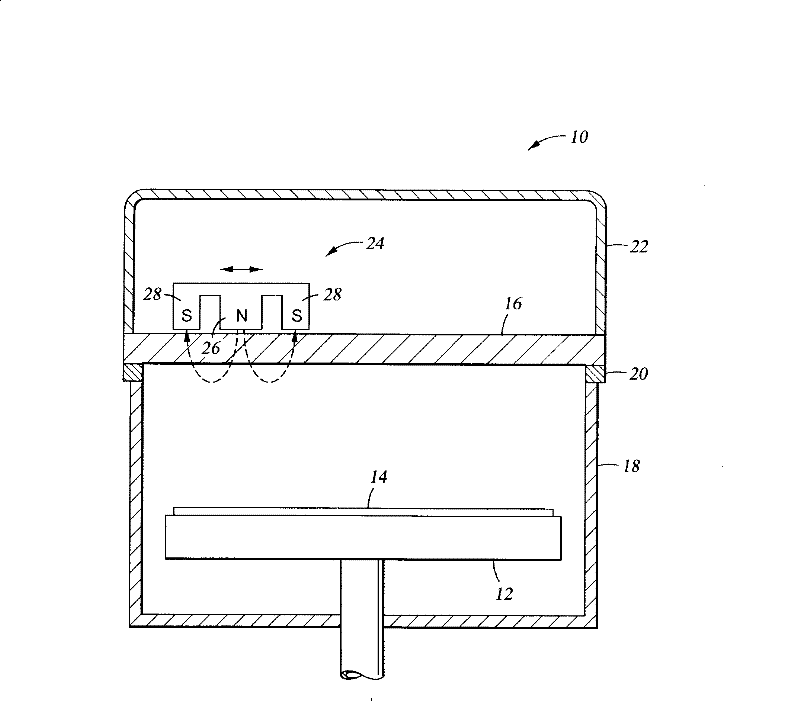

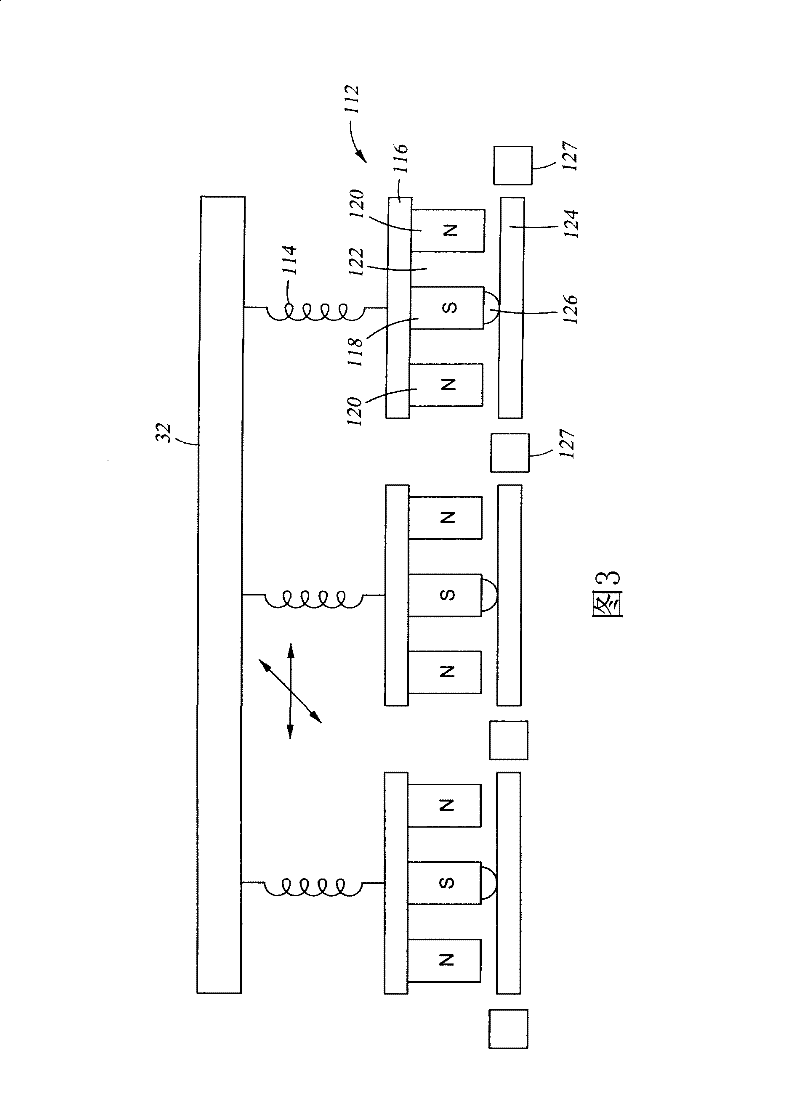

[0029] One embodiment of the source assembly of the present invention separates both the target and the magnetron into associated bar targets and bar magnetrons. The bar targets are supported on a separate target holder and the bar magnetrons are supported on a separate scanning support plate so that the magnetrons are linked during scanning.

[0030] Another embodiment includes a magnetron suitable for use in a ganged magnetron assembly or other magnetron configuration.

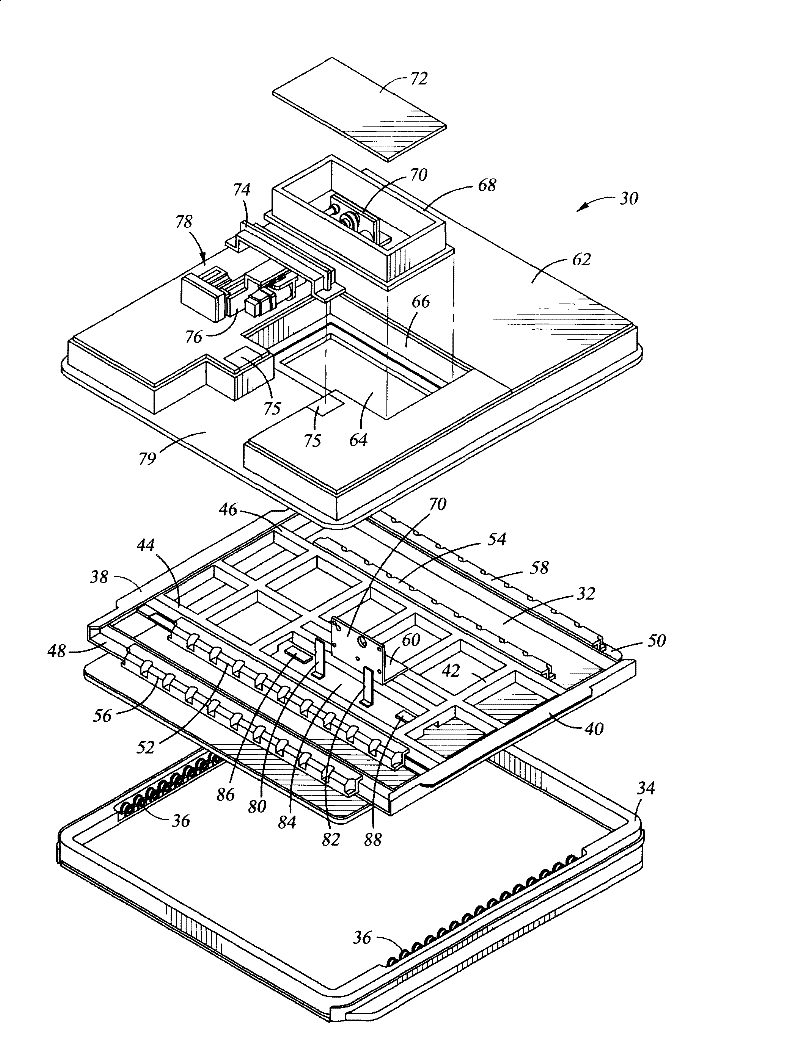

[0031] exist figure 2 The two-dimensional scanning mechanism 30 shown in the orthogonal view is close to the scanning mechanism described by Le et al. Submitted applications should be considered in more detail. However, the scanning mechanism 30 supports a large support plate 32 that is preferably composed of a non-magnetic material such as aluminum, and the scanning mechanism 30 can scan the large support plate 32 in an arbitrary two-dimensional pattern. In contrast, Tepman and Le's setup scans a single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com