Hydraulic self-operated three-way valve

A self-operated, three-way valve technology, used in multi-way valves, lift valves, valve details, etc., can solve the problems of inability to meet the main circuit, bypass switching, difficulty in key control valves, and difficulty in control, etc. High performance requirements, compact structure, and the effect of ensuring flow requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

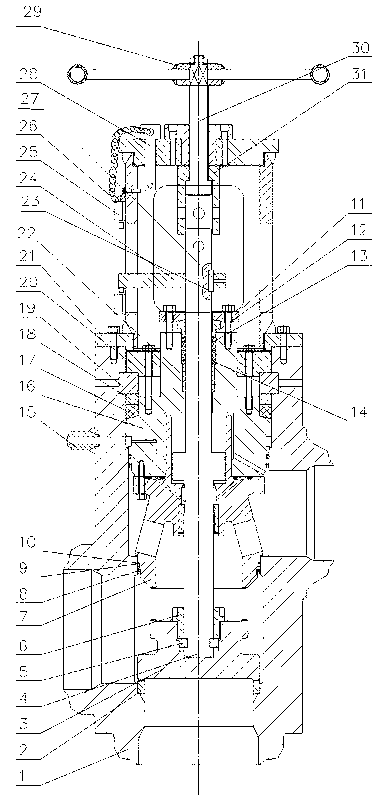

[0030] In order to further understand the hydraulic self-operated three-way valve, the description is as follows in conjunction with the accompanying drawings.

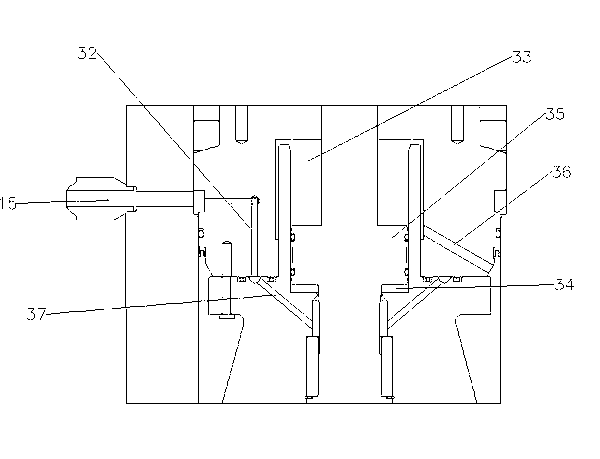

[0031]It includes a handle 29, a valve stem 4, an upper valve stem 30, a valve body 1 and a valve flap 3, and is characterized in that it also includes a piston upper cavity 33, a piston lower cavity 34, an upper piston cavity inlet passage 36 and an outlet of the piston lower cavity Passage 37, handle 29 is connected with upper valve stem 30, and upper valve stem 30 is fixed in the middle of bracket 21, and upper valve stem 30 both sides are provided with pipe sleeve 31, and bracket 21 is provided with limit pin 28, and limit pin 28 and lock chain 26 are connected, the chain 26 is fixed on the bracket 21 by bolts, the bracket 21 at the lower end of the chain 26 is provided with a limit switch 25, the valve stem 4 is connected with the pipe sleeve 31, and the upper valve stem 30 and the valve stem 4 are located between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com