Double-Y-axis jig transferring device and method for automatic screw machine

A transfer device, screw machine technology, applied in the direction of manufacturing tools, comprehensive factory control, metal processing equipment, etc., can solve the problems of increased operating costs, low efficiency of single Y-axis locking, and cannot meet the needs of production and processing, and achieve machine The effect of optimizing operating efficiency and maximizing the degree of machine automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]To make the object, technical solution and advantages of embodiments of the present invention more clear, the following will be combined with the accompanying drawings in an embodiment of the present invention, the technical solution in the embodiment of the present invention is clearly and completely described.

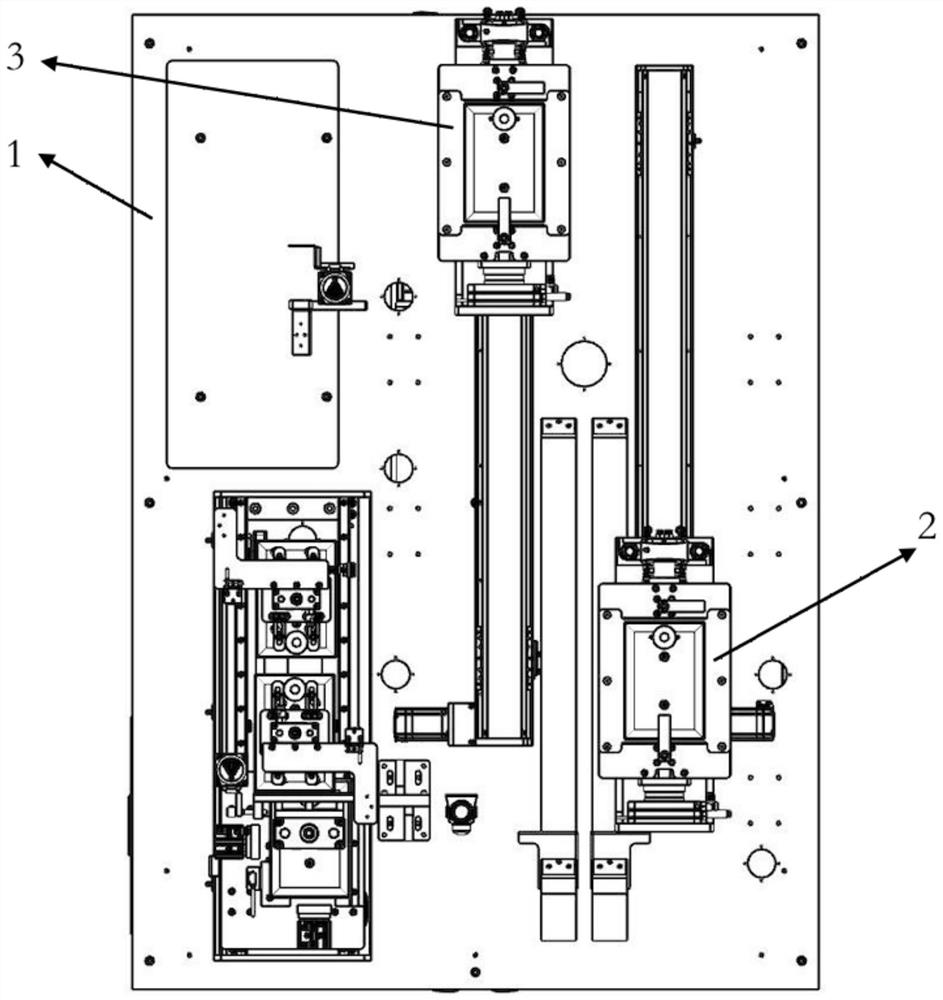

[0035] as Figure 1-7 As shown, the present invention provides a double Y-axis fixture load transfer device of an automatic screw machine, comprising a table 1, a first fixture carrier transfer mechanism disposed on the workbench 1 located at the unloading workpiece point 2 and a second fixture transfer mechanism disposed on the workbench 1 located on the workpiece point 3;

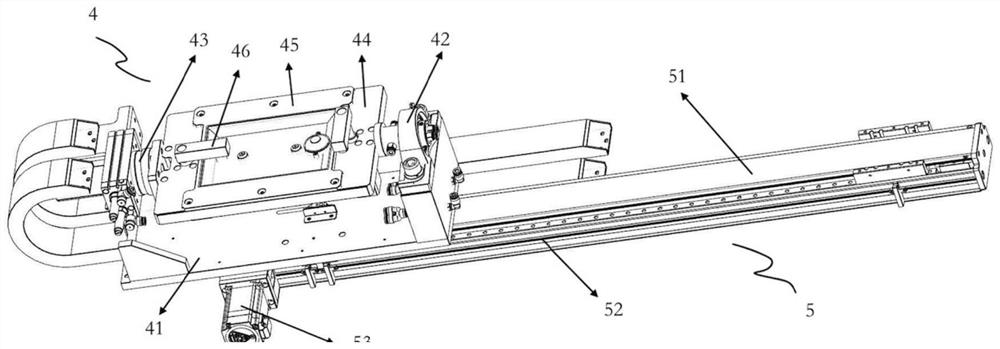

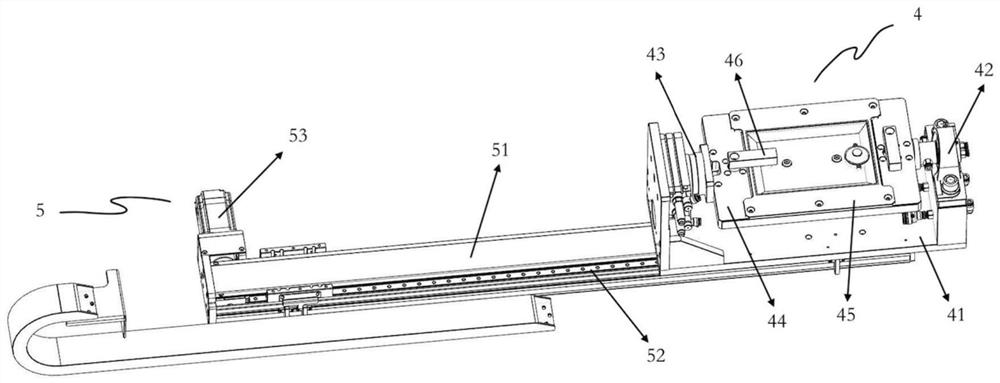

[0036] In order to improve the efficiency of the screw machine to the workpiece lock screw, the double Y-axis fixture carrier transfer mechanism can be set up to move and process two workpieces at the same time. The structure of the two fixture carrier mechanisms is exactly the same, and both a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com