Lifting system of crane

A hoisting system and crane technology, applied in the direction of the clockwork mechanism, the hoisting device, etc., can solve the problems of a set of transmission mechanism braking, etc., and achieve the effects of improving life, avoiding accidents, and increasing safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

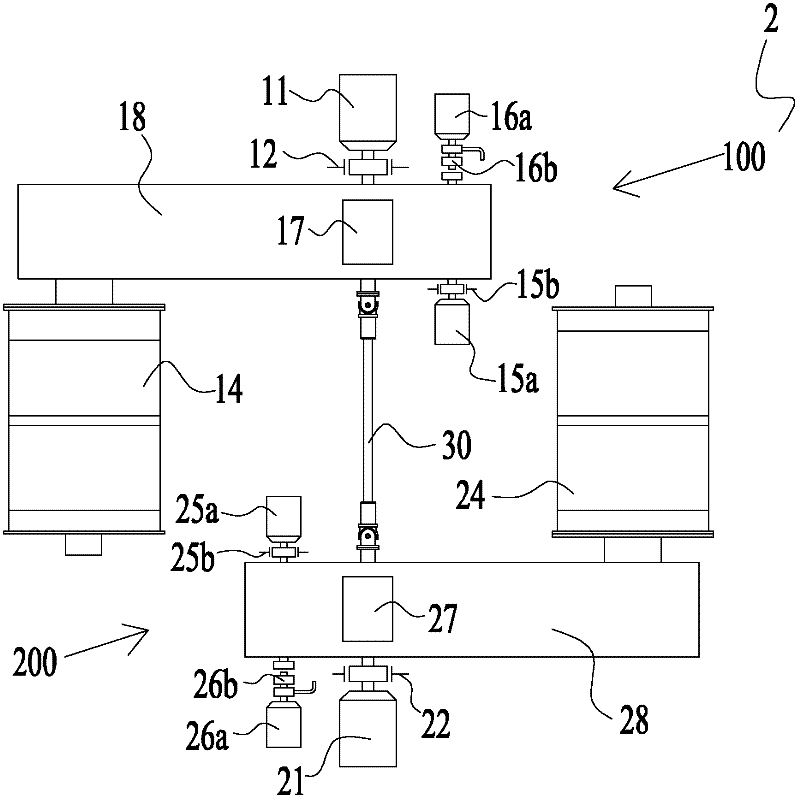

[0015] Please refer to figure 2 , which is a schematic top view of a preferred embodiment of the hoisting system of the crane of the present invention. Such as figure 2 As shown, the hoisting system 2 of the crane of the present invention includes two sets of "motor-reducer-drum" transmission mechanisms 100 and 200 that are independent and opposite to each other. The transmission mechanism 100 includes a motor 11 , a motor braking device 12 , a planetary reducer 18 and a reel 14 connected to the planetary reducer 18 by transmission. In addition, the transmission mechanism 100 also includes a tilting motor 15 a and a braking device 15 b for the tilting motor. The planetary reducer 18 is a multi-stage reducer, including a planetary package 17 . The transmission mechanism 200 includes a motor 21 , a motor braking device 22 , a planetary reducer 28 and a reel 24 connected to the planetary reducer 28 by transmission. In addition, the transmission mechanism 200 also includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com