A coal mine surface horizontal well segmental dynamic coal digging method for diameter expansion

A horizontal well and surface technology, which is applied to drilling equipment and methods, earthwork drilling, wellbore flushing, etc., can solve the problems of underground gas drainage safety hazards, large engineering volume, and high cost, and achieve the elimination of safety hazards and improve The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in conjunction with the accompanying drawings.

[0024] In the mine preparation area and development preparation area, the horizontal wells on the coal mine surface are arranged along the direction of the mining face. The horizontal wells have three openings for the shaft structure, three openings for completion of the open hole, and lowering of the glass fiber reinforced plastic casing. The gas pre-drainage by segmental dynamic coal digging and expansion method will greatly improve the extraction efficiency and increase the productivity of horizontal wells.

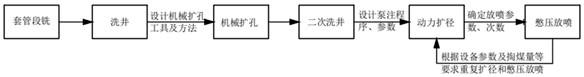

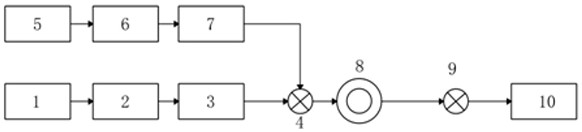

[0025] The technical solution adopted in the present invention is: to carry out dynamic diameter expansion in the target interval of the horizontal section of the coalbed methane horizontal well, and the technological process is to carry out casing section milling and mechanical reaming in the designed target horizontal section, and then use high-pressure atomized air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com