Coking coal moisture adjusting technology

A technology for coal moisture conditioning and coking coal, applied in coke ovens, petroleum industry and other directions, can solve the problems of poor adaptability, high power consumption and high investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

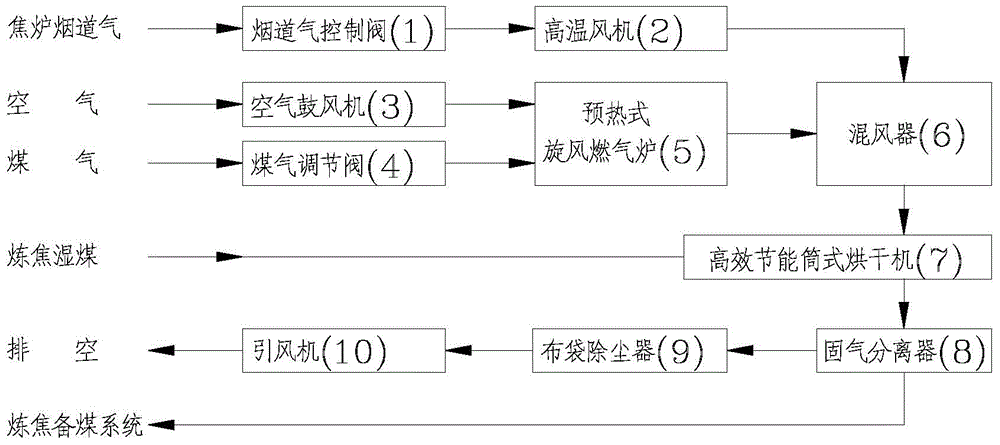

Method used

Image

Examples

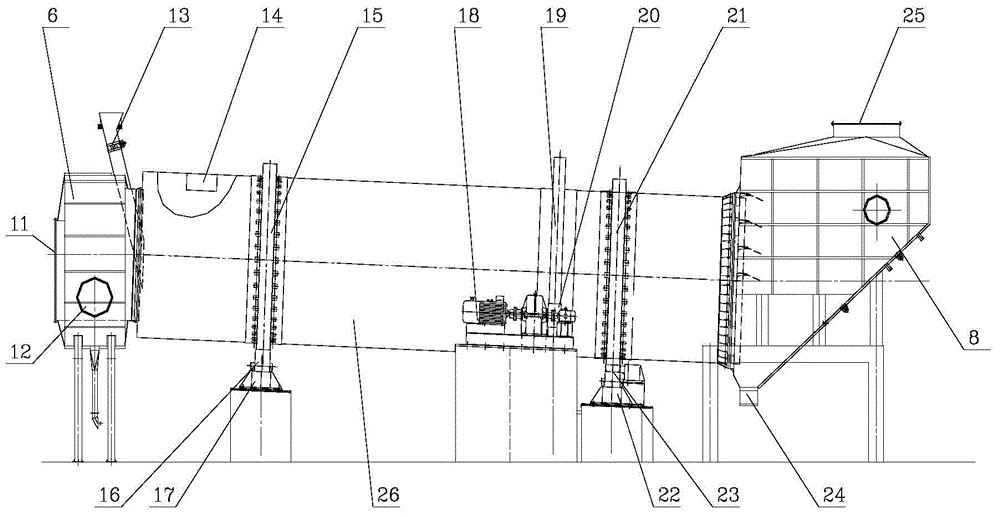

Embodiment 1

[0101] The high-efficiency and energy-saving drum dryer is composed of a drum (26), a vibrating feeding chute (13), a lifting plate (14), a front roller device, a driving device and a rear roller device. The drum (26) consists of The feed end to the discharge end are arranged in a slope from high to low, with a slope of 2-3 0 , the drum (26) is equipped with an air mixer (6) at the feed end, a solid-gas separator (9) is installed at the discharge end, and a vibrating feeding chute (13) is provided above the feed end of the drum (26), and the drum ( 26) There is a lifting plate (14) inside the cylinder, a drive device is installed in the middle of the drum (26), and a front roller device and a rear roller device are arranged on both sides of the driver device. The front roller device is composed of the front roller ring (15 ), the front support wheel (16) and the front support frame (17), the rear support wheel device is composed of the rear support wheel ring (21), the rear su...

Embodiment 2

[0128] This example is a coal humidity control system for a stamped coke oven.

[0129] 1. Coal humidity control system parameters and calculation results

[0130] Dry coal volume for coal humidity control: G=180000kg / h;

[0131] The maximum flue gas volume extracted by coal humidity control: Q 1 =160,000 Nm 3 / h;

[0132] Moisture on wet basis before coal feed into dryer: W 1 =16%;

[0133] Moisture on a wet basis after the coal material leaves the dryer: W 2 =11%;

[0134] Temperature of coal material before entering the dryer: T 1 =20℃;

[0135] Temperature of coal after leaving the dryer: T 2 =60℃;

[0136] Flue gas temperature before entering the dryer: T 3 =220℃;

[0137] Exhaust gas temperature after leaving the dryer: T 6 =80℃;

[0138] Heat dissipation coefficient of dryer: k=0.08;

[0139] The gas is coke oven gas, and the low calorific value of coke oven gas is q=4000kcal / Nm 3 , the air excess coefficient of burning coke oven gas is taken as 1.2.

...

Embodiment 3

[0153] This example is a coal humidity control system for a stamped coke oven.

[0154] 1. Coal humidity control system parameters and calculation results

[0155] Dry coal volume for coal humidity control: G=280000kg / h;

[0156] The maximum flue gas volume extracted by coal humidity control: Q 1 =160,000 Nm 3 / h;

[0157] Moisture on wet basis before coal feed into dryer: W 1 =18%;

[0158] Moisture on a wet basis after the coal material leaves the dryer: W 2 =11%;

[0159] Temperature of coal material before entering the dryer: T 1 =20℃;

[0160] Temperature of coal after leaving the dryer: T 2 =60℃;

[0161] Flue gas temperature before entering the dryer: T 3 =160℃;

[0162] Exhaust gas temperature after leaving the dryer: T 6 =80℃;

[0163] Heat dissipation coefficient of dryer: k=0.08;

[0164] The gas is coke oven gas, and the low calorific value of coke oven gas is q=4000kcal / Nm 3 , the air excess coefficient of burning coke oven gas is taken as 1.2.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com