Thick coal seam top and bottom linkage horizontal well subsection seam making, coal washing and outburst eliminating method

A technology for horizontal wells and thick coal seams, which is applied in earthwork drilling, wellbore/well components, gas discharge, etc., and can solve problems such as heavy construction workload, high construction cost, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

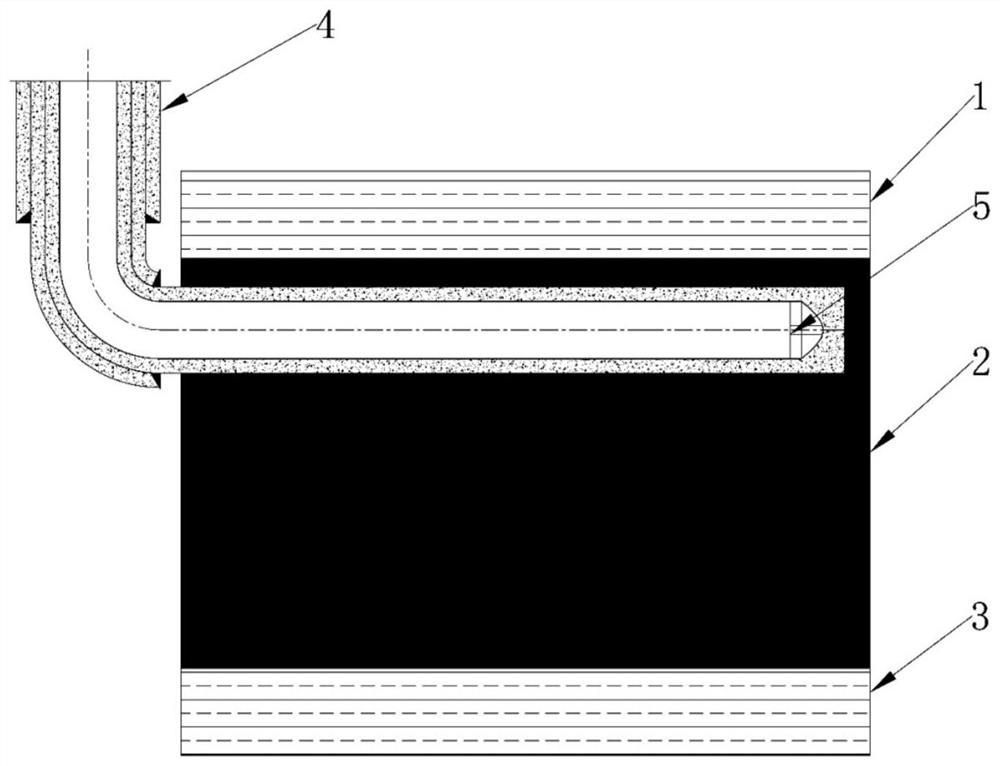

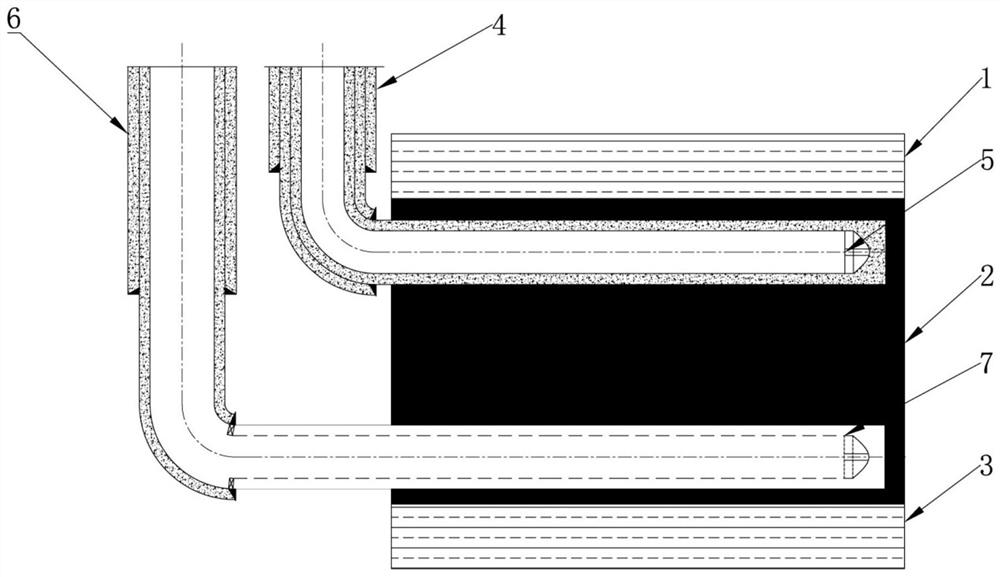

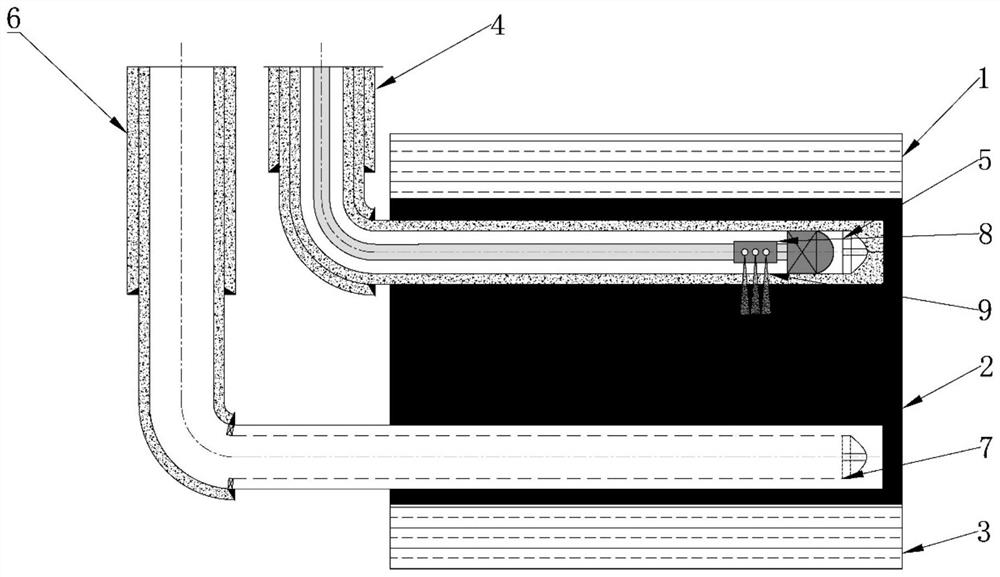

[0037] see Figure 1-Figure 7 , showing the method for jointing the top and bottom of the thick coal seam with the horizontal well to create fractures and wash coal and eliminate outbursts in stages, which is mainly used for gridding and outburst elimination in thick coal seams.

[0038] Wherein, the method for jointing horizontal wells at the top and bottom of the thick coal seam to create seams and wash coal to eliminate outbursts may include the following steps:

[0039] Step 1: Drill an L-shaped top horizontal well 4 on the top of the coal seam 2, and the top horizontal well 4 is drilled into the casing 5 three times, and the whole well section is cemented and completed (such as figure 1 );

[0040] Specifically, the horizontal section of the L-shaped top horizontal well 4 is located at the top of the coal seam 2 within the range of 0-0.5m below the rock formation of the coal seam roof 1, and the top horizontal well 4 adopts a three-open shaft structure, and the top horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com