Wide-area underwater coal-rock deep-hole pressure-bearing micro-explosion grouting water plugging method

A coal rock and grouting technology, which is applied in the wide-area underwater coal rock deep hole pressurized micro-explosion grouting water blocking field, can solve the problem that the surrounding rock drilling cannot accurately communicate with the water channel, the penetration is not large, and the increase in drilling The amount and cost of drilling holes can be solved, and the effect of increasing the range of blasting energy, weakening the intensity of concentrated action, and expanding the range of pressure relief and cracking can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

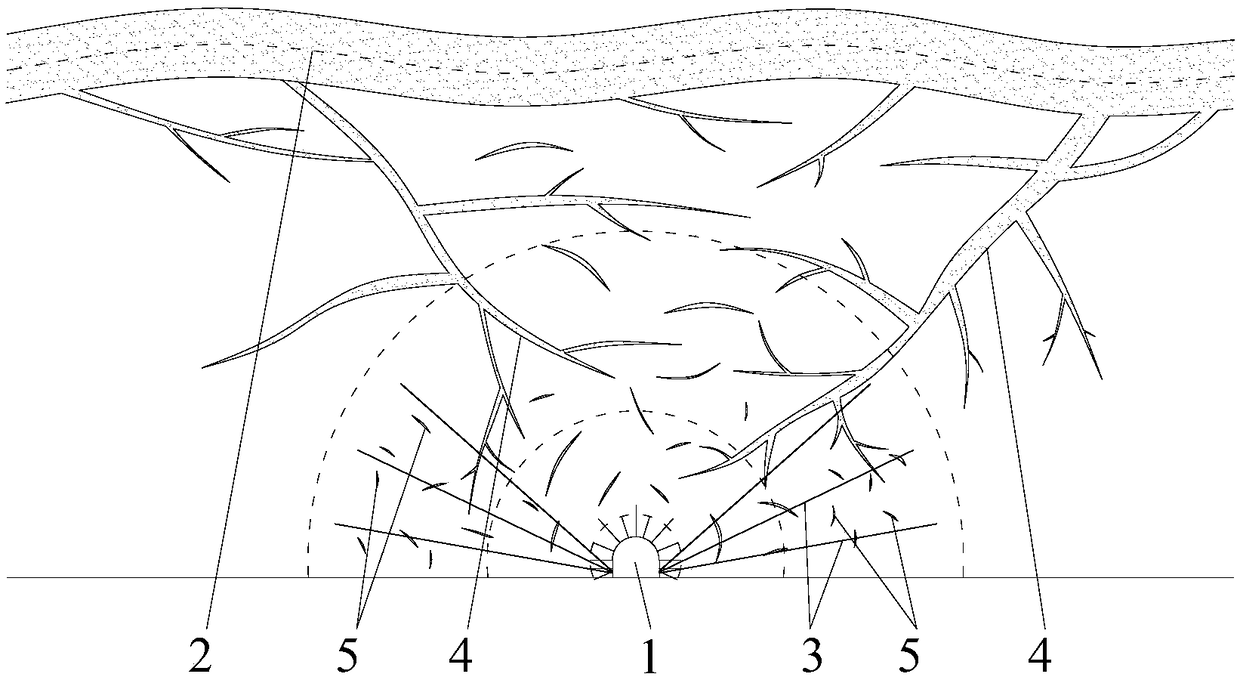

[0031] Taking the deep-hole pressurized micro-explosion grouting water plugging under the condition of water-rich roadway 1 overlying rock aquifer 2 and wide-area water-rich conditions as an example, the drilling 3 grouting plugging operation is carried out to realize the surrounding rock dominant water fissure 4 and secondary water conduction The wide area of fissure 5 is fully blocked. The present invention will be further described in conjunction with accompanying drawing:

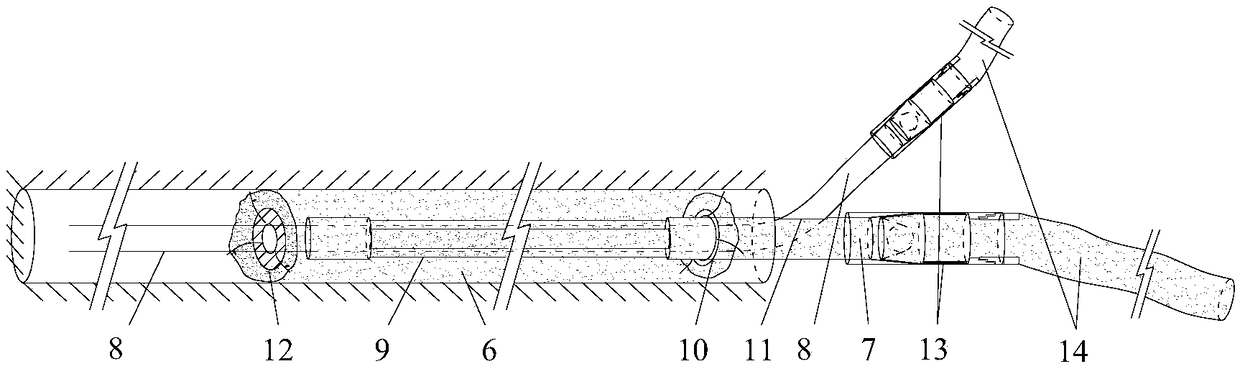

[0032] like figure 1 and figure 2 As shown, it is assumed that the depth of the drilling 3 in the surrounding rock of the rich water roadway 1 is 25m, and the diameter of the drilling is 100mm. The length of the designed drilling and grouting sealing section 6 is 15m. The hole spacing is kept at 1-3m, and solid explosives are used for micro-explosive cracking of coal and rock, and 2MPa mine water is used as the explosion medium.

[0033] Using the deep hole pressure micro-explosion method, pre-cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com