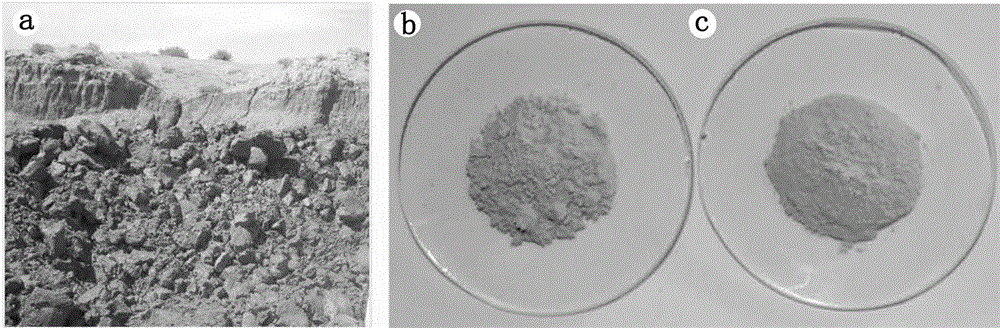

Method for preparing micro-nano hybrid mesoporous adsorbing microspheres by utilizing red attapulgite clay

A technology of attapulgite clay and adsorption microspheres, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., to achieve the effects of high-value utilization, easy process control, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

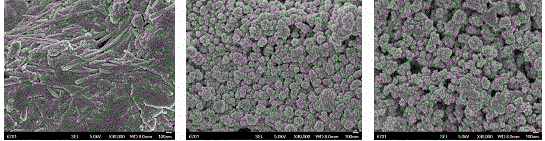

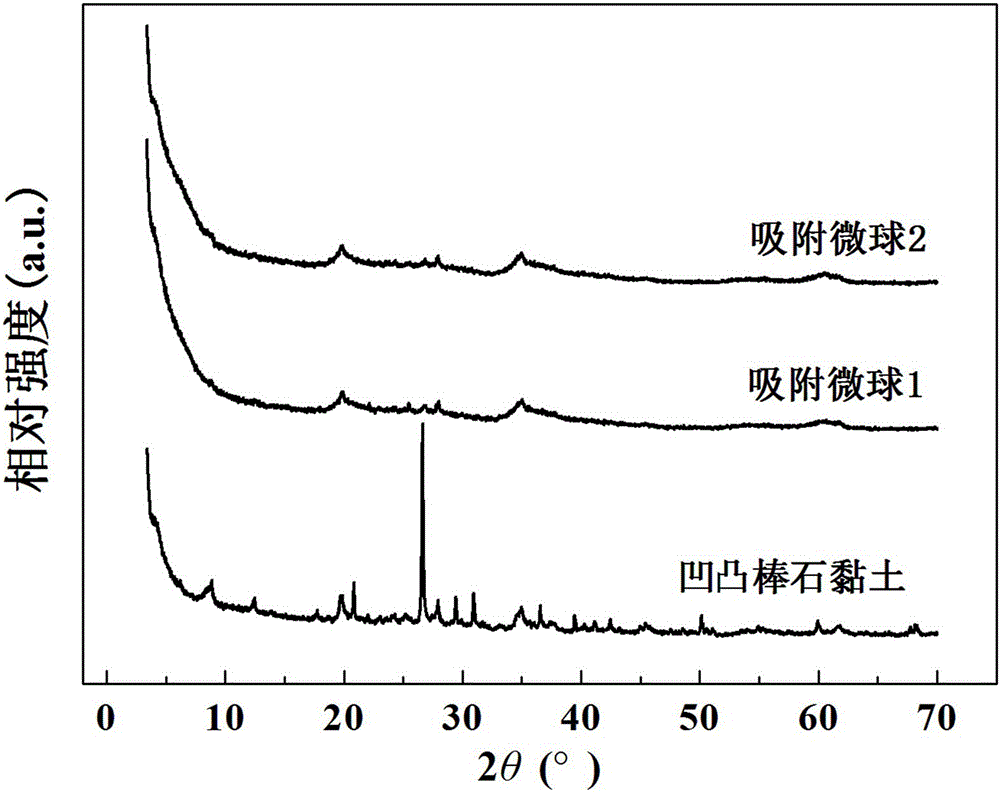

[0023] Example 1: Mix 100g of attapulgite clay mineral powder with 10g of sodium silicate and grind for 4 hours, then heat-treat with microwave at 140°C for 0.5; disperse the obtained product into 800mL of an aqueous solution containing 0.25g of citric acid, and then add 7.5 150mL aqueous solution of 1g magnesium chloride and 2.5g zinc chloride, fully stirred, transferred to a 2L hydrothermal reaction kettle, reacted at 260°C for 48h, and cooled to room temperature at 10°C / min; the solid product was separated, washed with water, and vacuum After drying and crushing, the off-white adsorption material was obtained.

Embodiment 2

[0024] Example 2: Mix 100g of attapulgite clay mineral powder with 100g of potassium metasilicate, grind for 4h, then heat-treat with microwave at 80°C for 4h; disperse the obtained product into 800mL of an aqueous solution containing 2g of ethylenediaminetetraacetic acid, and then Add 150mL of aqueous solution containing 60g of magnesium nitrate and 20g of zinc nitrate, stir well, transfer to a 2L hydrothermal reaction kettle, react at 160°C for 2h, and cool down to room temperature at 10°C / min; separate the solid product, wash with water, Vacuum dried and crushed to obtain off-white adsorption material.

Embodiment 3

[0025] Example 3: Mix 100g of attapulgite clay mineral powder with 50g of sodium potassium silicate and grind for 4 hours, then heat it with microwave at 100°C for 1 hour; disperse the obtained product into 800mL of aqueous solution containing 0.5g of oxalic acid, and then add 49.5 150 mL of aqueous solution of 1 g of magnesium acetate and 0.5 g of zinc acetate, stirred well, transferred to a 2L hydrothermal reaction kettle, reacted at 180°C for 24 hours, and cooled to room temperature at 10°C / min; the solid product was separated, washed with water, and vacuum After drying and crushing, the off-white adsorption material was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com