Method for extracting natural saponin and biosurfactant composite product

A bio-surface and active agent technology, applied in the field of extracting natural and bio-surfactant composite products, can solve the problems of insufficient and efficient utilization of carbohydrates and high surface tension of natural saponin, reducing energy consumption and efficient utilization of raw materials , the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

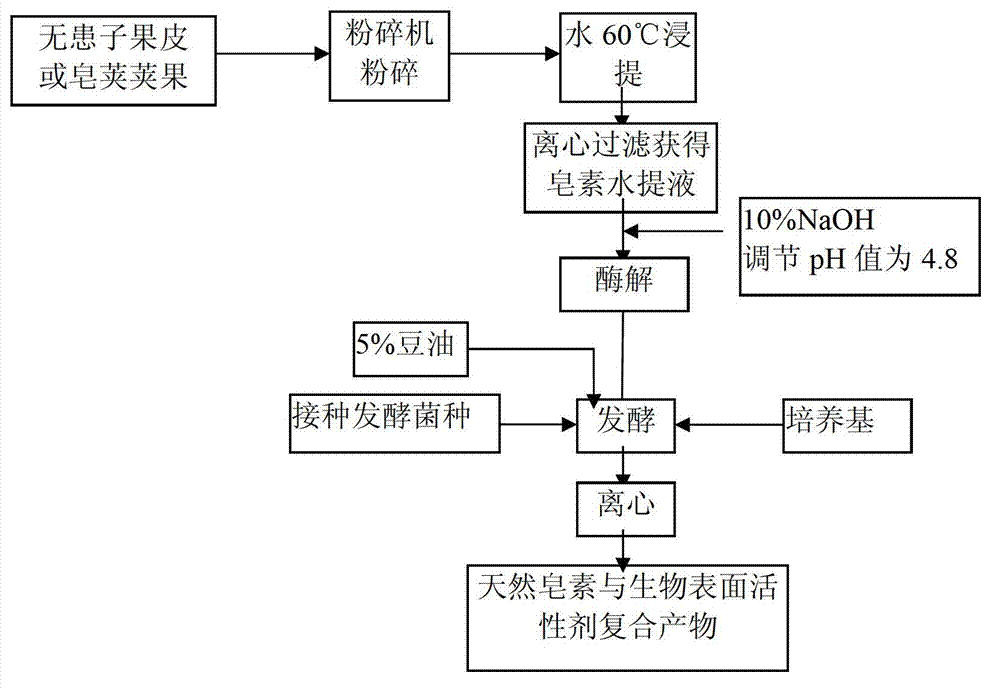

[0072] Such as figure 1 Shown, the method concrete process of extracting natural saponin and biosurfactant composite product of the present invention is as follows:

[0073] The air-dried Sapindus fruit peel is removed to remove impurities and iron, the electric pulverizer pulverizes the peel, passes through a 12-mesh sieve, and vibrates and extracts saponin in a constant temperature shaker at 60°C and 150 revolutions, wherein the weight ratio of raw materials to water is 1: 6. The extraction time is 5h. Place the extract in a centrifuge with a rotating speed of 3000rpm, centrifuge for 15min, and collect the supernatant, which is the aqueous extract of Sapindus chinensis.

[0074] With 10% NaOH solution, add 1-2 drops dropwise to adjust the pH value of the solution to 4.8. Add 450 IU cellobiase / L to the solution, and carry out saccharification and hydrolysis for 96 hours in a full-temperature shaking incubator at 45° C. and 180 rpm.

[0075] The enzyme hydrolyzate was used ...

Embodiment 2

[0077] Such as figure 1 Shown, the method concrete process of extracting natural saponin and biosurfactant composite product of the present invention is as follows:

[0078] Remove impurities and iron from the air-dried acacia pods, crush the pericarp with an electric pulverizer, pass through a 12-mesh sieve, and extract saponin by vibrating in a constant temperature shaker at 60°C and 150 rpm, wherein the weight ratio of raw materials to water is 1:8, The extraction time is 5h. The extract is placed in a centrifuge with a rotating speed of 3000rpm, centrifuged for 15min, and the supernatant is collected, which is the aqueous extract of saponins.

[0079] With 10% NaOH solution, add 1-2 drops dropwise to adjust the pH value of the solution to 4.8. Add 450 IU cellobiase / L to the solution, and carry out saccharification and hydrolysis for 96 hours in a full-temperature shaking incubator at 45° C. and 180 rpm.

[0080] The enzyme hydrolyzate was used as the fermentation substr...

Embodiment 3

[0082] Such as figure 1 Shown, the method concrete process of extracting natural saponin and biosurfactant composite product of the present invention is as follows:

[0083] The air-dried Sapindus fruit peel is removed to remove impurities and iron, the electric pulverizer pulverizes the peel, passes through a 20-mesh sieve, and vibrates and extracts saponin in a constant temperature shaker at 60°C and 150 revolutions, wherein the weight ratio of raw materials to water is 1: 2. The extraction time is 4h. Place the extract in a centrifuge with a rotating speed of 3000rpm, centrifuge for 15min, and collect the supernatant, which is the aqueous extract of Sapindus chinensis.

[0084] With 10% NaOH solution, add 1-2 drops dropwise to adjust the pH value of the solution to 4.8. Add 450 IU cellobiase / L to the solution, and carry out saccharification and hydrolysis for 96 hours in a full-temperature shaking incubator at 45° C. and 180 rpm.

[0085] The enzyme hydrolyzate was used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com