Method for preparing red hybridized pigment from red attapulgite clay

A technology of attapulgite clay and attapulgite, applied in the direction of fibrous fillers, etc., can solve the problems of high cost, complicated process, no utilization, etc., and achieve the effect of good stability, uniform particle size, and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

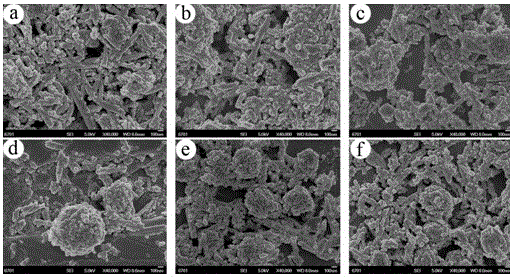

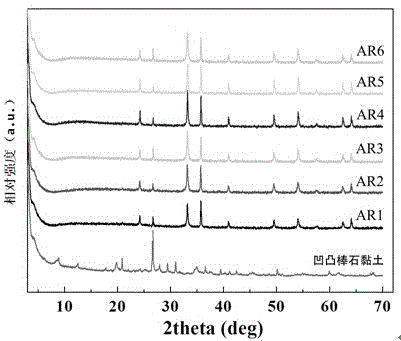

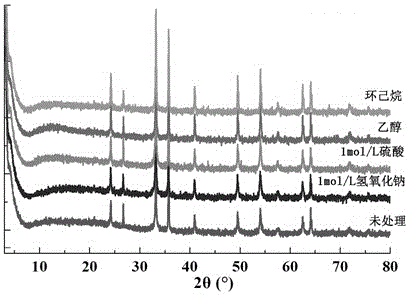

[0022] Mix 10g of red attapulgite clay treated with high-pressure homogenization with 100g of ferric chloride, grind it evenly and disperse it into 800mL of water; add 0.01g of chloroacetic acid, stir well, and ultrasonicate for 10min; transfer it to a 1L hydrothermal reaction kettle, Adjust the pH to 2, react at a temperature of 150°C, and a pressure of 5MPa for 48 hours; then cool down to room temperature at a rate of 15°C / min, and the solid product is separated, washed, dried, and pulverized to obtain a red hybrid pigment (No. AR1) . See Table 1 for the L, a, and b color values of the samples.

Embodiment 2

[0024] Mix 10g of ball-milled red attapulgite clay with 5g of ferric nitrate, grind it evenly and disperse it into 50mL of water; add 0.1g of peracetic acid, stir well, and ultrasonicate for 60min; transfer it into a 100mL hydrothermal reaction kettle, and adjust the pH To 1, react at a temperature of 280°C and a pressure of 2MPa for 48h; then cool down to room temperature at a rate of 15°C / min, and the solid product is separated, washed, dried, and pulverized to obtain a red hybrid pigment (code AR2). See Table 1 for the L, a, and b color values of the samples.

Embodiment 3

[0026]Mix 10g of acidified red attapulgite clay with 150g of iron acetate and 50g of iron acetylacetonate, grind them evenly and disperse them into 600mL of water; add 0.1g of glycine, stir well, and ultrasonicate for 10min; transfer to a 1L hydrothermal reaction kettle , adjust the pH to 5, react at a temperature of 200°C, and a pressure of 5MPa for 24 hours, and then cool down to room temperature at a rate of 15°C / min. The solid product is separated, washed, dried, and pulverized to obtain a red hybrid pigment (code AR3 ). See Table 1 for the L, a, and b color values of the samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com