Biomass-based nitrogen self-doped porous carbon material and preparation method and application thereof

A self-doping, porous carbon technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as the development limitation of carbon materials, reduce production costs, realize high-value utilization, and direct doping methods. effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

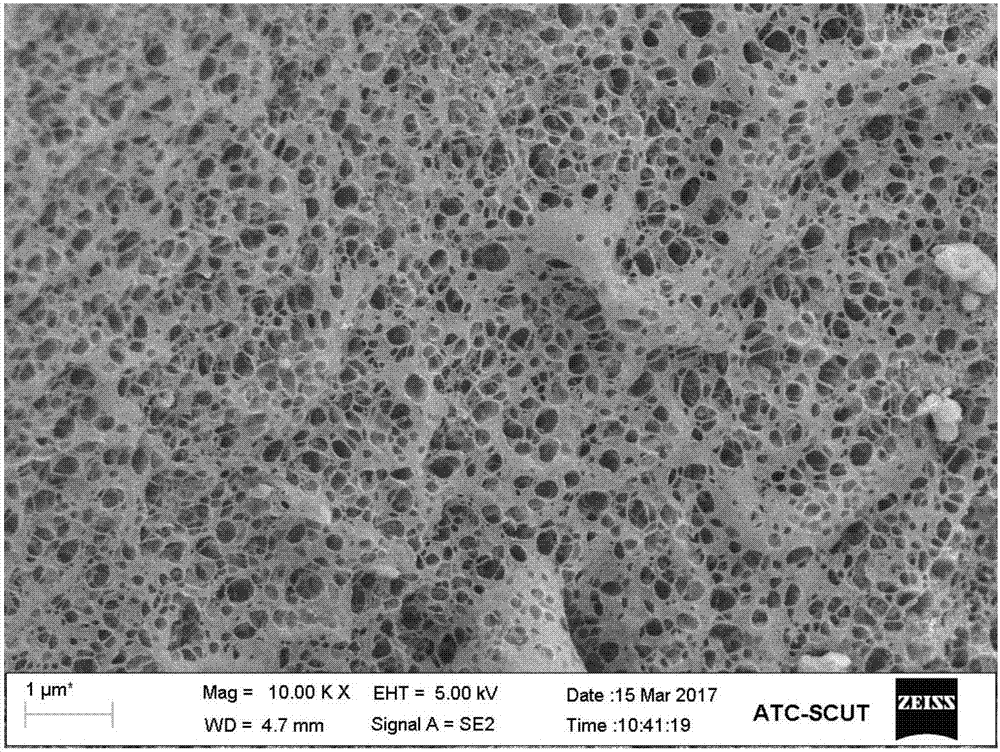

[0037] A preparation method of a biomass-based nitrogen self-doped porous carbon material in this embodiment, the specific preparation steps are as follows:

[0038] (1) Add 3g of chitosan and 60ml of deionized water into the reactor, seal and heat to 250°C, and stir for 4 hours at a constant temperature; after the reaction, cool to room temperature, take out the solid product in the reactor, and wash it with deionized water , drying the washed product to obtain a high-temperature water-treated pre-carbonized product;

[0039] (2) Add a certain quality of KHCO into the beaker 3 , adding a small amount of water will KHCO 3 dissolved, and the pre-carbonized product was added to the beaker (KHCO 3 The mass ratio to the pre-carbonized product is 1:1) Stir evenly, and dry the mixture; then carbonize and activate the above-mentioned dried mixture in a nitrogen atmosphere, heat up from room temperature at 3°C / min to the target temperature of 750°C, and keep it warm 1 hour; after t...

Embodiment 2

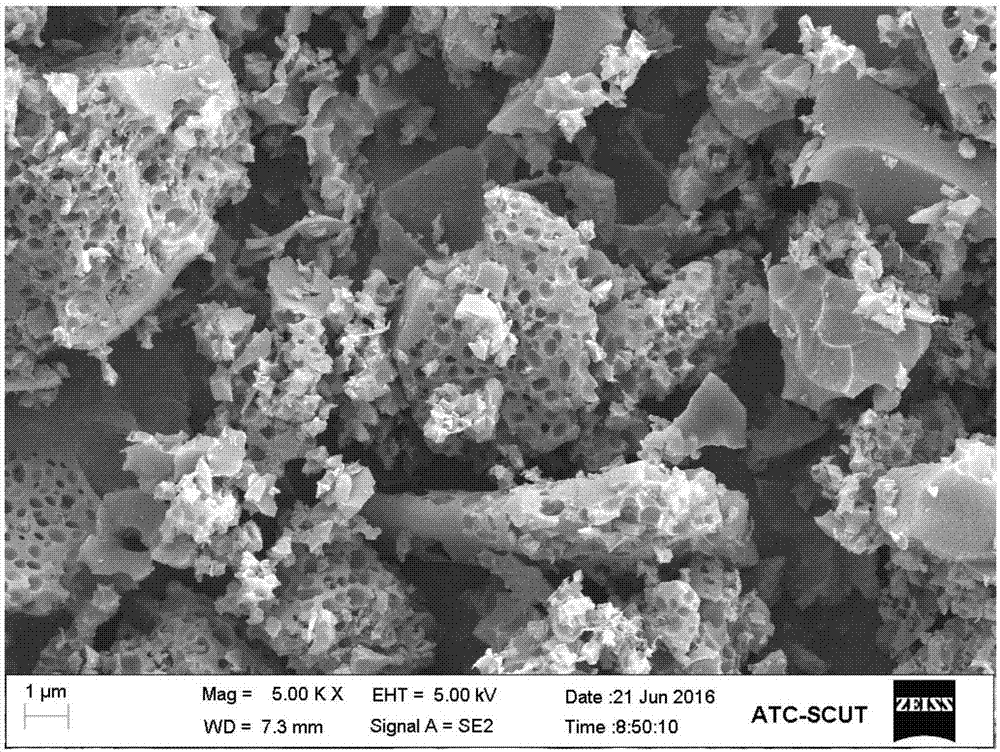

[0043] A preparation method of a biomass-based nitrogen self-doped porous carbon material in this embodiment, the specific preparation steps are as follows:

[0044] (1) Add 3g of chitin and 60ml of deionized water into the reactor, seal and heat to 250°C, and stir for 4 hours at a constant temperature; after the reaction, cool to room temperature, take out the solid product in the reactor, wash it with deionized water, drying the washed product to obtain a high-temperature water-treated pre-carbonized product;

[0045] (2) Add a certain quality of KHCO into the beaker 3 , adding a small amount of water will KHCO 3 dissolved, and the pre-carbonized product was added to the beaker (KHCO 3 The mass ratio to the pre-carbonized product is 1:1) Stir evenly, and dry the mixture; then carbonize and activate the above-mentioned dried mixture in a nitrogen atmosphere, heat up from room temperature at 3°C / min to the target temperature of 750°C, and keep it warm 1 hour; after the reac...

Embodiment 3

[0048] A preparation method of a biomass-based nitrogen self-doped porous carbon material in this embodiment, the specific preparation steps are as follows:

[0049] (1) Add 3g of chitosan and 30ml of deionized water to the reactor, seal and heat to 180°C, and stir at a constant temperature for 2 hours; after the reaction, cool to room temperature, take out the solid product in the reactor, wash it with tap water, and The washed product is dried to obtain a high-temperature water-treated pre-carbonized product;

[0050] (2) Add a certain amount of NaOH in the beaker, add a small amount of water to dissolve NaOH, add the pre-carbonized product to the beaker (the mass ratio of NaOH and pre-carbonized product is 1:1) and stir evenly, and dry the mixture; then The above-mentioned dried mixture was carbonized and activated in a nitrogen atmosphere, and the temperature was raised from room temperature to the target temperature of 750 °C at a rate of 3 °C / min, and kept for 1 hour; af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com