Method for preparing large-particle foam carbon by using corncob

A corncob and large particle technology, which is applied in the field of preparing large particle foamed carbon by using corncob, can solve the problems of non-biodegradation, high production cost, difficult degradation of foamed carbon, etc., and achieves high-value utilization and improved opening. The effect of high efficiency and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of pre-hydroxymethyl urea modified starch adhesive

[0030] (a) Add cornstarch and distilled water into the reactor, stir evenly, and prepare a cornstarch emulsion with a concentration of 40%,

[0031] (b) Heat up to 60°C, add ferrous sulfate accounting for 0.1% of the mass of corn starch, stir evenly, then add hydrogen peroxide accounting for 6% of the mass of corn starch, and oxidize for 30 minutes;

[0032] (c) Raise the temperature to 90±2°C, adjust the pH=3.0, add polyvinyl alcohol with a mass fraction of 10%, and react for 60 minutes;

[0033] (d) Add sodium hydroxide, adjust the pH of the reaction solution to 8.5, and gelatinize for 20 minutes; then add paraformaldehyde and react for 30 minutes;

[0034] (e) adjust the pH of the reaction solution to 6.0 with formic acid, add urea for 20 minutes of cross-linking reaction, and obtain the pre-hydroxymethyl urea modified starch adhesive;

[0035] Wherein, the mass ratio of cornstarch,...

Embodiment 2

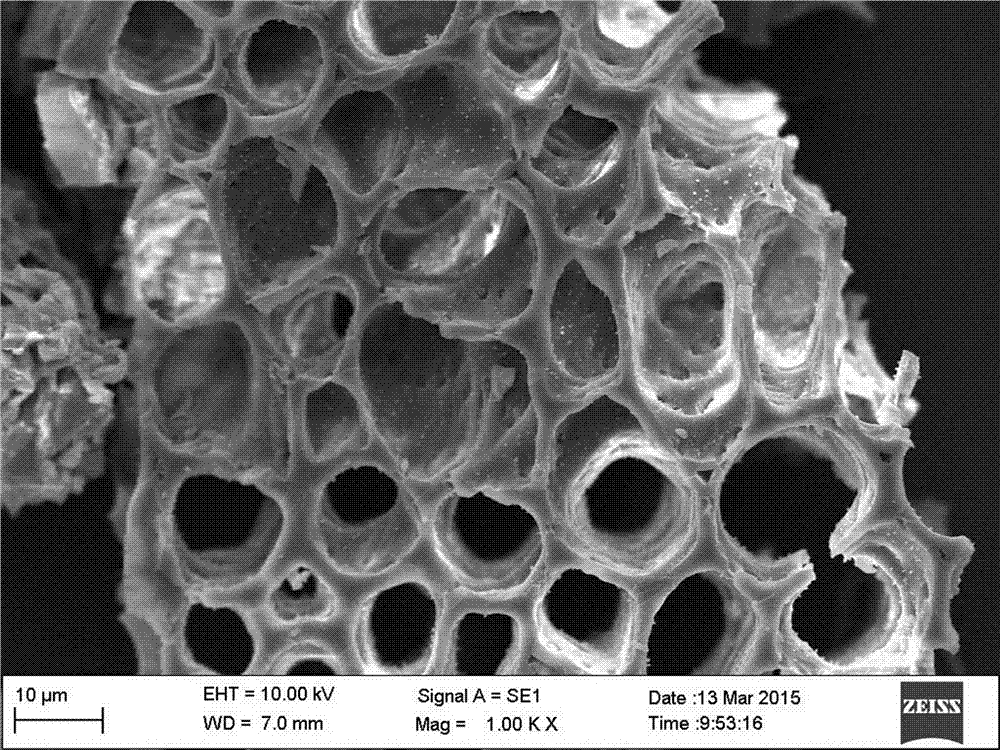

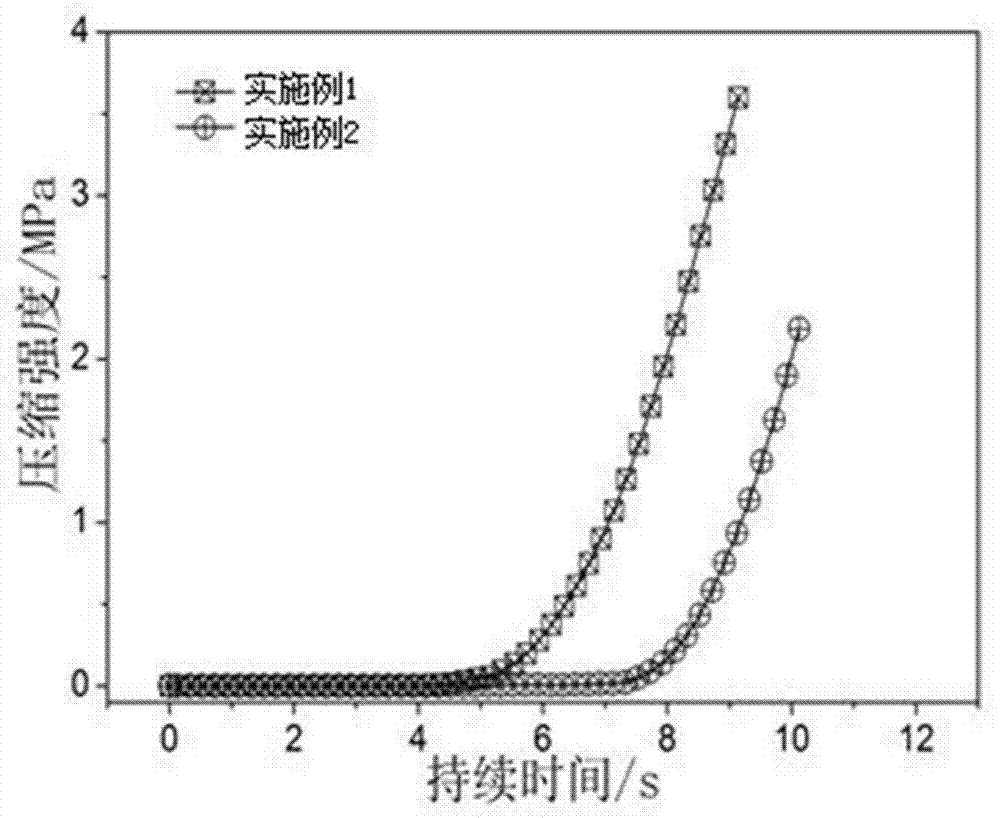

[0036] Example 2 Preparation of Large Particle Foamed Carbon

[0037] A kind of method that utilizes corncob to prepare large particle foamed charcoal, concrete steps are as follows:

[0038] (1) Dry the corn cob until the moisture content is lower than 12%, and then crush it to form 60-mesh corn cob powder;

[0039](2) Add 750g of sulfuric acid solution with a mass fraction of 20% into the reaction kettle, turn on the stirrer, stir at a rate of 150-180 rpm, slowly add 300 g of corncob powder, and carry out in-situ polycondensation reaction for 30 minutes under acid catalysis;

[0040] (3) Add 150 g of the pre-hydroxymethylurea-modified starch adhesive obtained in Example 1 to the reactor, heat up to 80°C, react for 60 minutes, then cool to 40°C, and centrifuge until the solid content is not less than 65%. , the centrifugation rate was 5000 rpm, and the brown viscous opaque liquid obtained was the biomass-based expandable slurry. The viscosity was 3890 mpa.s, the solid con...

Embodiment 3

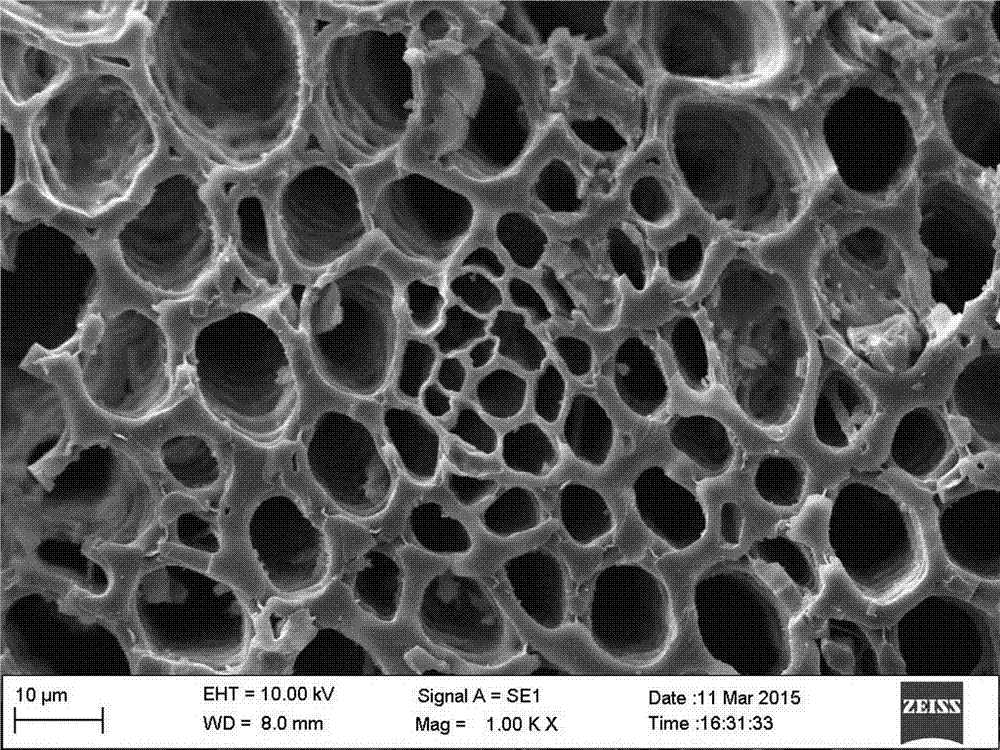

[0046] A kind of method that utilizes corncob to prepare large particle foamed charcoal, concrete steps are as follows:

[0047] (1) Dry the corn cob until the moisture content is lower than 12%, and then crush it to 90 mesh;

[0048] (2) Add 650 g of phosphoric acid solution with a mass fraction of 20% into the reactor, turn on the agitator, slowly add 300 g of corncobs, and carry out the in-situ polycondensation reaction for 40 min under acid catalysis;

[0049] (3) Add 100 g of pre-hydroxymethyl urea modified starch adhesive to the reaction kettle, raise the temperature to 80°C, react for 60 minutes, then cool down to 40°C, and centrifugally dehydrate until the solid content is 70%, and the obtained brown sticky The opaque liquid is the biomass-based expandable slurry. Its viscosity is 4530 mpa.s, its solid content is 71.35%, and its pH is 6.0.

[0050] (4) To the biomass-based expandable slurry obtained in step 3, add glycerol, 3.6% OP-10, and 6% azobis Formamide, 6% n-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com