Sulfomethylated alkali lignin-formaldehyde-sulfonated acetone polymer coal water slurry additive

A technology of sulfomethylated alkali lignin and sulfonated acetone, which is applied in the field of coal water slurry dispersants, can solve the problems of poor dispersion and viscosity reduction performance, weak adsorption of additives and coal particle surfaces, poor stability of coal water slurry, etc. problems, to achieve the effect of increasing the degree of sulfonation and molecular weight, good product stability, and improving product dispersibility and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

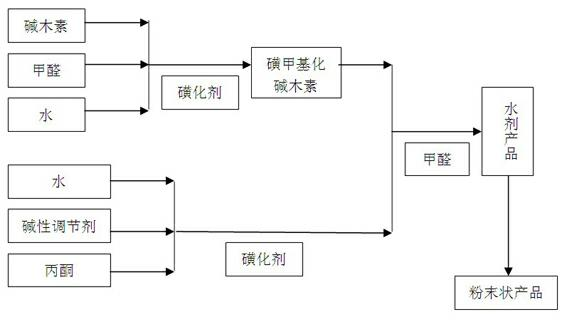

Method used

Image

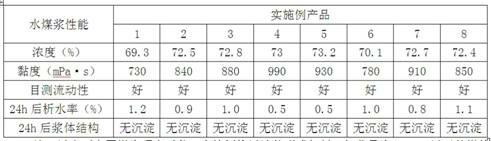

Examples

Embodiment 1

[0026] 1) The raw material components used in this embodiment are as follows:

[0027] Alkali lignin (extracted from kraft eucalyptus pulp black liquor): 134 kg;

[0028] Sodium metabisulfite: 27 kg;

[0029] Sodium sulfite: 53.5 kg;

[0030] Sodium hydroxide: 1.5 kg

[0031] Acetone: 20 kg;

[0032] Formaldehyde (37%): 80 kg;

[0033] Water: 684 kg.

[0034] 2) Preparation process steps and process parameters:

[0035] The preparation of the present invention is carried out under normal pressure:

[0036] (a) Add 20 kg of formaldehyde solution to a reactor containing 134 kg of alkali lignin and 310 kg of water, raise the temperature to 40°C, and react for 3.0 hours, then add 27 kg of sodium metabisulfite, raise the temperature to 95°C, and react After 2.0 hours, sulfomethylated alkali lignin is produced.

[0037] (b) Add 374 kg of water, 0.7 kg of sodium hydroxide, and 20 kg of acetone into the reactor in sequence, stir evenly, add 53.3 kg of sodium sulfite, raise the...

Embodiment 2

[0038] 1) The raw material components used in the present embodiment are as follows:

[0039] Alkali lignin (extracted from alkaline bamboo and bagasse pulp black liquor, the mass ratio of bamboo and bagasse is 1:3): 115 kg;

[0040] Sodium bisulfite: 23 kg;

[0041] Sodium sulfite: 46 kg;

[0042] Potassium hydroxide: 1.0 kg

[0043] Acetone: 57 kg;

[0044] Formaldehyde (37%): 86 kg;

[0045] Water: 672 kg.

[0046] 2) Preparation process steps and process parameters:

[0047] The preparation of the present invention is carried out under normal pressure:

[0048] (a) Add 20 kg of formaldehyde solution to a reactor containing 115 kg of alkali lignin and 200 kg of water, raise the temperature to 55°C, and react for 3.0 hours, then add 23 kg of sodium bisulfite, and raise the temperature to 100°C , After 2.0h of reaction, sulfomethylated alkali lignin was produced.

[0049] (b) Add 472 kg of water, 1.0 kg of potassium hydroxide, and 57 kg of acetone to the reactor in sequ...

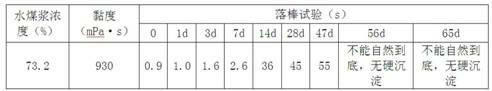

Embodiment 3

[0050] 1) The raw material components used in the present embodiment are as follows:

[0051] Alkali lignin (extracted from soda birch pulp black liquor): 166 kg;

[0052] Sodium sulfite: 70 kg;

[0053] Sodium phosphate: 8 kg

[0054] Acetone: 104 kg;

[0055] Formaldehyde (37%): 54 kg;

[0056] Water: 598 kg.

[0057] 2) Preparation process steps and process parameters:

[0058] The preparation of the present invention is carried out under normal pressure:

[0059] (a) Add 18 kg of formaldehyde solution to a reactor containing 166 kg of alkali lignin and 278 kg of water, raise the temperature to 55°C, and react for 3.0 hours, then add 23 kg of sodium sulfite, raise the temperature to 90°C, and react for 2.0 After h, make sulfomethylated alkali lignin.

[0060] (b) Add 320 kg of water, 8 kg of sodium phosphate, and 104 kg of acetone into the reactor in sequence, stir evenly, add 47 kg of sodium sulfite, raise the temperature to 65°C, and react for 2.0 hours, then add t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com