Method for preparing iron oxide red hybridization pigment by means of clay minerals

A technology of clay minerals and pigments, applied in chemical instruments and methods, inorganic pigment treatment, fibrous fillers, etc., can solve the problems of poor acid resistance, iron red color is not bright enough, and has no color, etc., to achieve good dispersion and bright color , the effect of stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

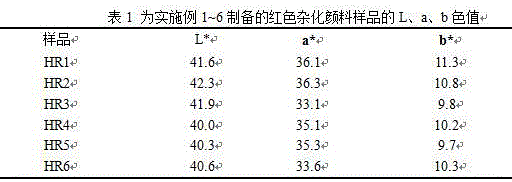

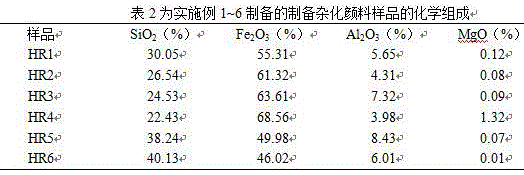

Embodiment 1

[0026] Weigh 10g of bentonite mineral powder that has been crushed and treated by rollers and ball mill for 12min, soak it with an aqueous solution containing 200g of ferric chloride for 2h, stir and mix evenly, then disperse it into 600mL of water, then add 0.15g of tartaric acid, stir well, Then transfer to a 1L hydrothermal reaction kettle, react at a temperature of 160°C and a pressure of 2MPa for 5h, and then cool down to room temperature at a rate of 10°C / min; the solid product is separated, washed, dried, and pulverized to obtain a red complex Chemical pigment (code HR1).

Embodiment 2

[0028] Weigh 100g of Yimeng clay mineral powder that has been crushed and roller-treated, and after ball milling for 120min, soak it with an aqueous solution containing 50g of ferric nitrate for 2h, mix it evenly with mechanical stirring, then disperse it into 400mL of water, add 0.1g of benzoic acid, and Stir evenly, then transfer to a 1L hydrothermal reaction kettle, react at a temperature of 300°C and a pressure of 8MPa for 60h, and then cool down to room temperature at a rate of 10°C / min; the solid product is separated, washed, dried, and pulverized. A red hybrid pigment (code HR2) was obtained.

Embodiment 3

[0030] Weigh 50g of crushed and roller-treated vermiculite ore powder and ball mill for 60min, soak it in an aqueous solution containing 100g of ferric sulfate for 2h, stir and mix evenly, then disperse it into 500mL of water, and then add 0.5g of ethylenediaminetetraacetic acid, Stir well, then transfer to a 1L hydrothermal reaction kettle, react at a temperature of 180°C and a pressure of 3MPa for 24h, then cool down to room temperature at a rate of 10°C / min, and separate, wash, dry, and pulverize the solid product Finally, a red hybrid pigment (No. HR3) is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com