Method for preparing large batch of binary superlattice emulsion balls

A superlattice and emulsion technology, which is applied in nanostructure manufacturing, nanotechnology for materials and surface science, formation of specific nanostructures, etc., can solve problems such as unfavorable material application value, multi-phase coexistence, material limitations, etc., to achieve Overcome the effects of inability to scale up large-scale preparation, simple assembly method, and controllable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Add 36 g iron oleate, 8 g oleic acid, 200 g 1-octadecene into a 500 ml three-necked bottle, and add a high-temperature magnet. After evacuating at 120° C. under the condition of stirring, the temperature was raised to 320° C. under an argon atmosphere, and kept at a constant temperature for 60 minutes, and then naturally cooled to obtain a brown or black reaction product. Next, add n-hexane, isopropanol and ethanol to the product, mix thoroughly, collect the precipitate by centrifugation, and dissolve it with n-hexane. After a uniform solution is formed, add isopropanol and methanol in turn, mix thoroughly, and The precipitate was collected and dispersed with n-hexane again to obtain 40 ml of oleic acid molecules as a ligand-protected uniform solution of 17 nm ferric oxide colloidal nanocrystals.

[0032] (2) Add 5.6 g of iron acetylacetonate, 2.0 g of cobalt acetylacetonate, 4.5 g of oleic acid, 21.0 g of oleylamine, and 25 ml of benzyl ether into a 250 ml three-ne...

Embodiment 2

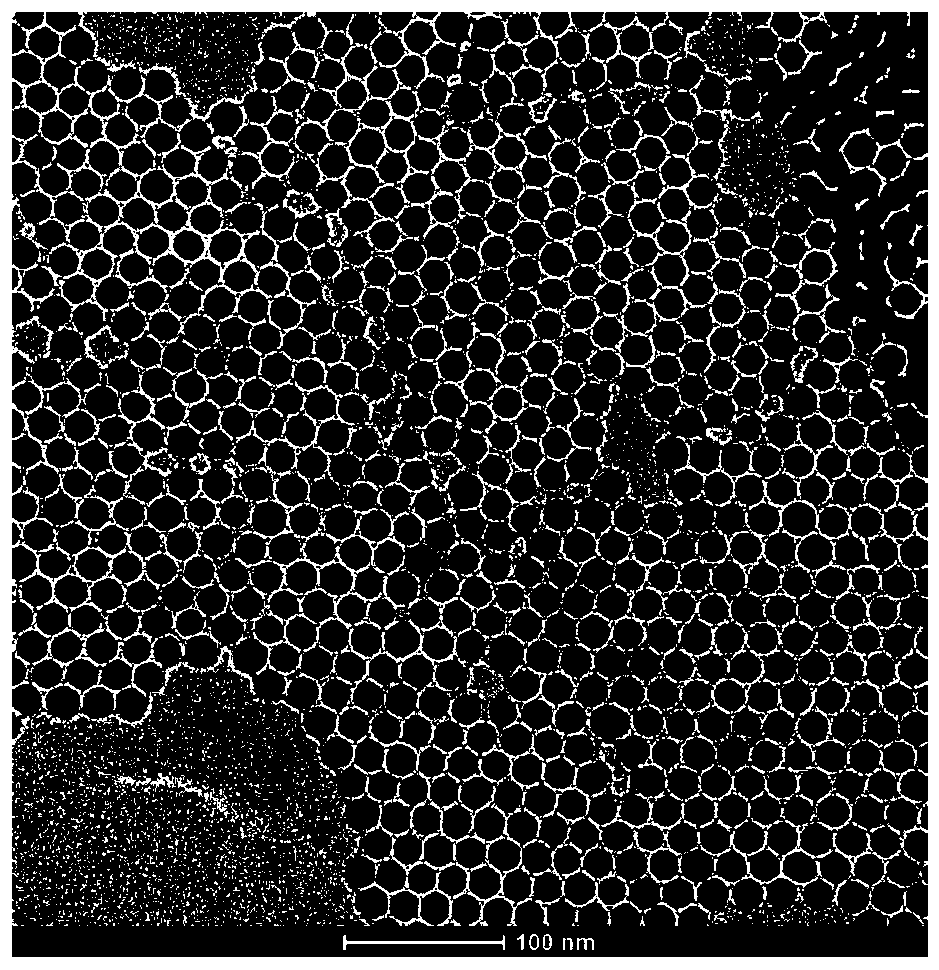

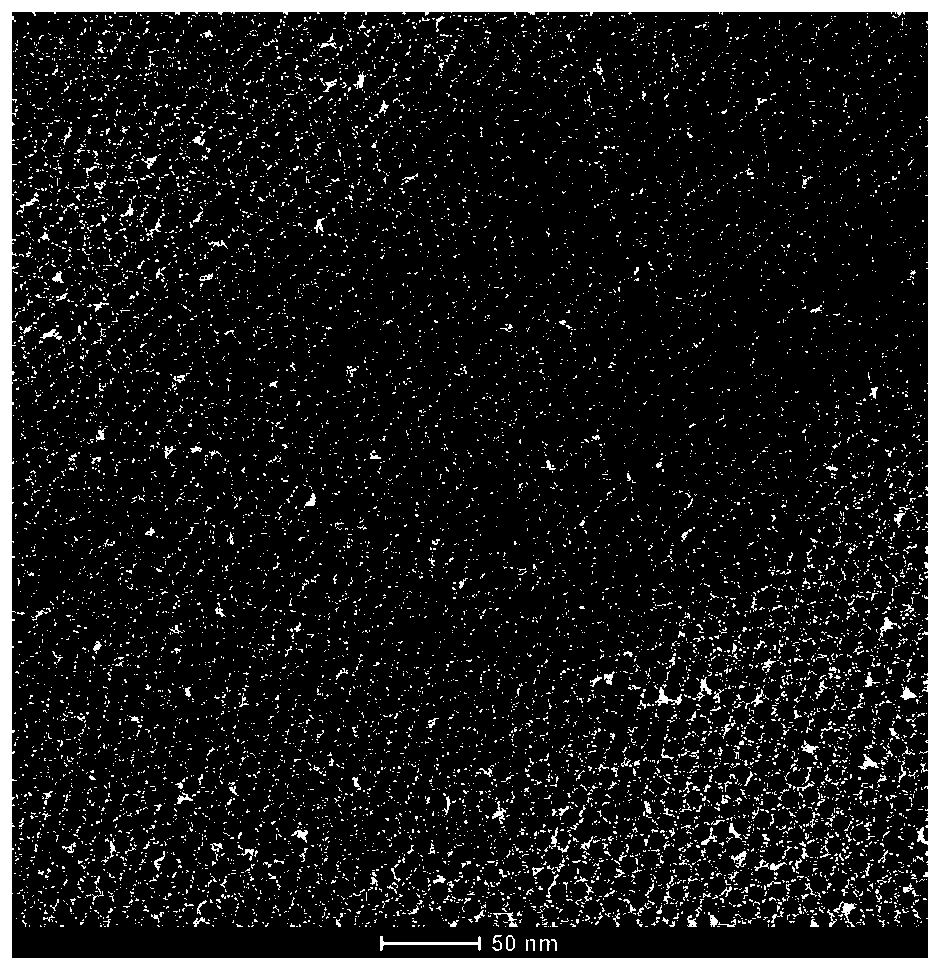

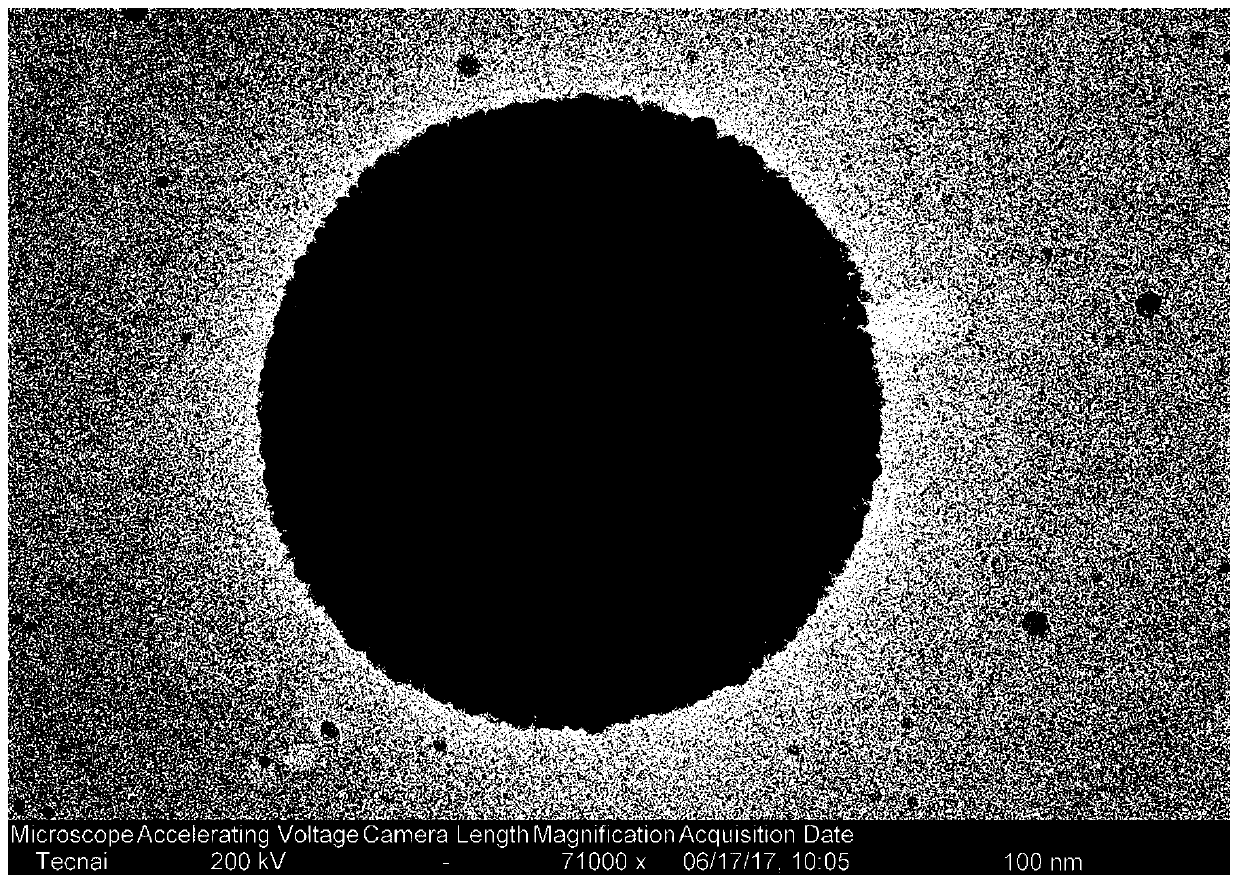

[0041] According to the basic steps of particle synthesis given in Example 1, by changing different synthesis conditions (reaction temperature, heating rate, reactant feed ratio), the particle size can be adjusted in the range of 2-20nm, excellent monodispersity and stable dispersion Inorganic nanoparticles in nonpolar solvents. The assembly method is the same as in Example 1, wherein the inorganic colloidal crystal nanoparticles are dispersed with chloroform, and 11nm iron ferric oxide particles and 4.5nm cobalt ferrite particles with a concentration of 10mg / mL are selected and mixed according to the ratio of the number of particles of 1:2. Take 10mL chloroform solution of particles, add 10mL sodium lauryl sulfate concentration to 100g / L deionized aqueous solution (volume ratio of oil phase to water phase is 1:1), emulsification rate is 12000rmp, homogenize for 5 minutes, And reacted under argon atmosphere at 20°C for 60 minutes, washed and separated to obtain 2 Morphology o...

Embodiment 3

[0043] The method is the same as in Example 1-2, the inorganic colloidal crystal nanoparticles are dispersed with toluene solvent, 7nm iron ferric oxide particles and 5nm cobalt ferrite particles with a concentration of 200mg / mL are selected, and mixed according to the ratio of the number of particles of 1:5, taking Add 1mL of particle chloroform solution to 100mL polyethylene glycol octylphenyl ether concentration of 2g / L deionized aqueous solution (volume ratio of oil phase to water phase is 1:100), emulsification rate is 2000rmp, homogeneity is 30 Minutes, and react under nitrogen atmosphere at 70°C for 30 minutes, wash and separate to obtain 5 Morphology of binary superlattice materials. After mixing particles of different types and sizes according to a certain concentration ratio, this method can be used to synthesize a series of binary superlattice materials with spherical emulsion shapes, including type AB, AB 2 Type, AB 3 Type, AB 4 Type, AB 5 Type, AB 6 Type, AB ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com