Preparation method and applications of super-hydrophobic SiO2 aerogel powder

A super-hydrophobic, aerogel technology, applied in chemical instruments and methods, inorganic chemistry, fibrous fillers, etc. Problems such as poor quality of aerogel powder, to achieve the effect of adjustable particle size distribution, short preparation cycle, and reduced production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

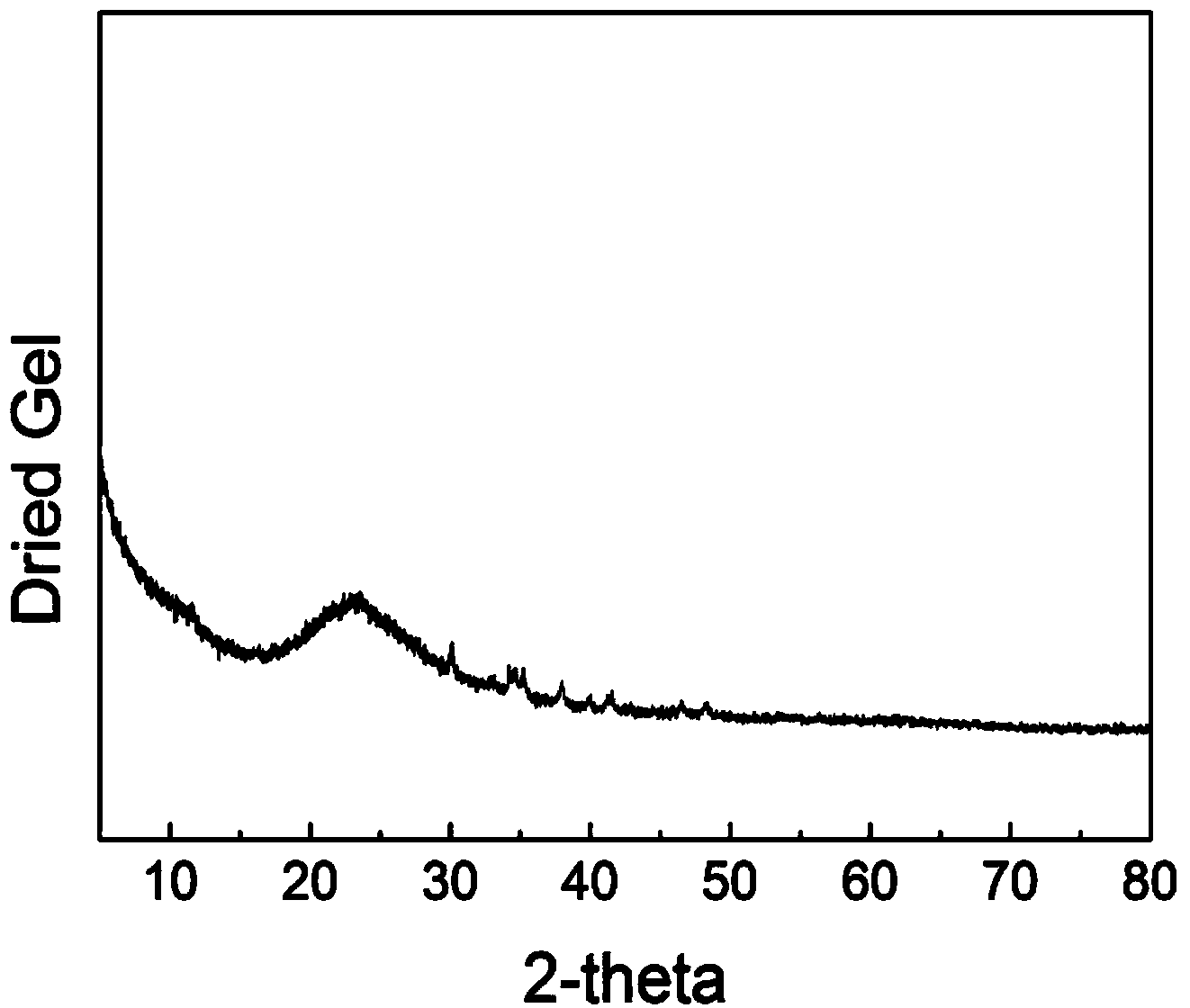

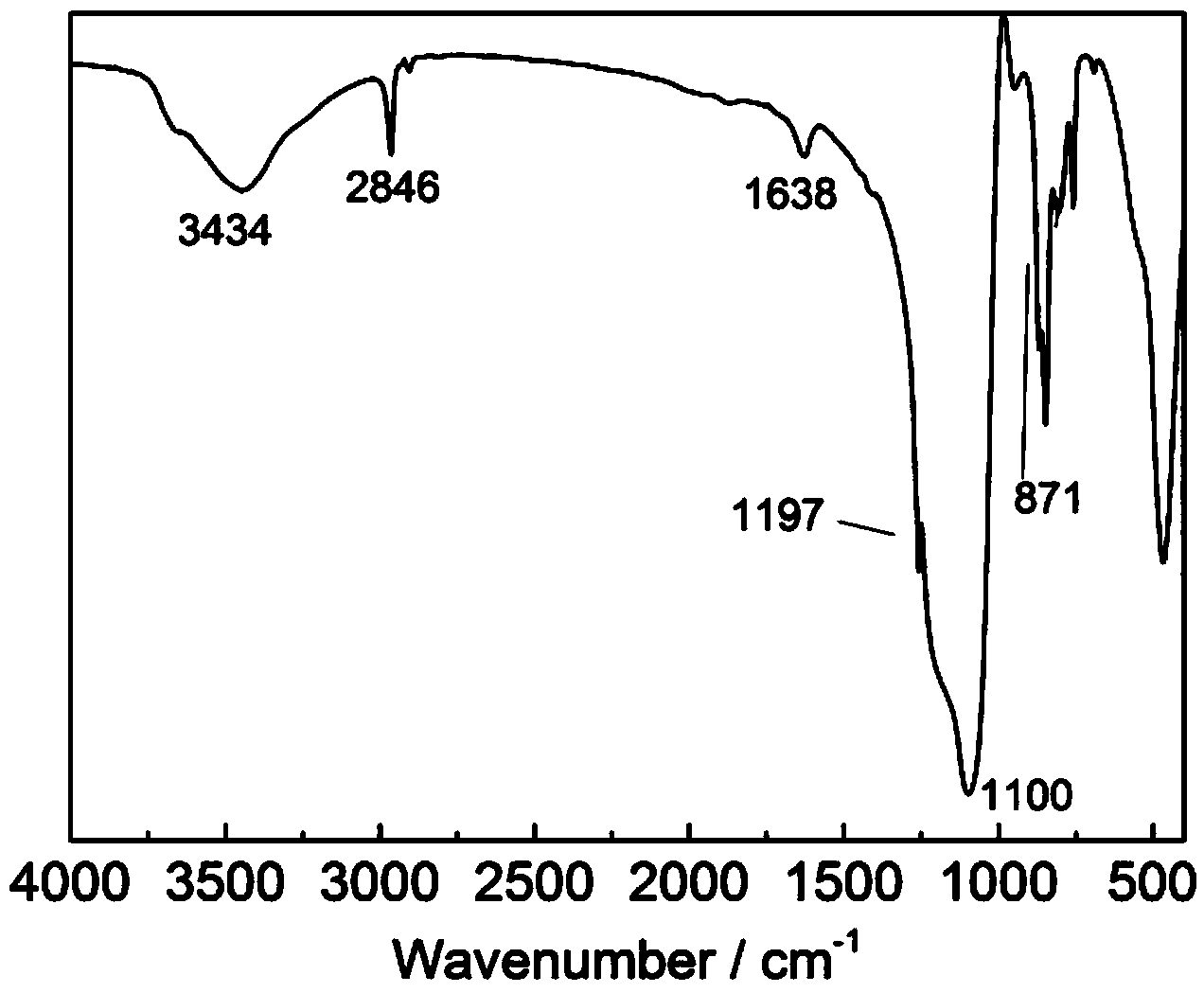

Embodiment 1

[0034] With 20% mass fraction of silicic acid sol as raw material, add 10ml kerosene and 2ml silicic acid sol in the container, and add 0.8g cetyltrimethylammonium bromide (CTAB) and 2.8g co-surfactant n-butyl alcohol. Use a 250rpm magnetic stirrer to stir until the liquid in the container changes from a milky white emulsion to a clear and transparent microemulsion. While stirring, add ammonia solution of pH ~ 12 dropwise, until the microemulsion is viscous, the reaction is completed, and fine wet gel particles are formed in the container. Add deionized water to the container, soak for 6h aging, wash with absolute ethanol, and filter with suction to remove kerosene and excess CTAB. The wet gel after suction filtration was replaced with alcohol and n-hexane as solvents for 2 hours and dispersed under ultrasonic waves at a frequency of 25 Hz for 1 hour. Use a solution of n-hexane and trimethylchlorosilane (TMCS) at a ratio of 2:1 for hydrophobic modification, wash the unreacte...

Embodiment 2

[0036]Dilute the sodium water glass with a modulus of 3.0 according to the water: water glass volume ratio (3:1), stir and filter evenly to obtain a water glass solution, add 10ml kerosene and 4ml water glass solution to the container, and add 4g dodecylsulfuric acid Sodium (SDS) and 3.5 g co-surfactant 2,4-hexanediol. Under stirring at 200 rpm, the liquid in the container changed from a milky white emulsion to a clear and transparent microemulsion. Add 2mol / L sulfuric acid solution dropwise while stirring, until the microemulsion is viscous, the reaction is completed, and wet gel particles are formed in the container. Add deionized water to the container, soak for 8 hours, age, wash alternately with absolute ethanol and deionized water, and filter 8 times to remove kerosene and excess SDS and Na + . The wet gel after suction filtration was replaced with alcohol and octane as solvents for 12 hours respectively. Use octane: TMCS (1:2) solution for solvent replacement and hyd...

Embodiment 3

[0038] Dilute sodium water glass with a modulus of 3.2 according to water: water glass volume ratio (4:1) and stir evenly, pass the diluted water glass through 732 sodium type strong acid styrene ion exchange resin to remove Na + , to obtain silicic acid sol. Take 20ml of heptane and 4ml of silicic acid sol, and add 1.6g of cetyltrimethylammonium bromide (CTAB) and 3.0g of co-surfactant n-butanol. Use a magnetic stirrer to stir until the liquid in the container changes from a milky white emulsion to a clear and transparent microemulsion. Add 2mol / L sodium hydroxide solution dropwise while stirring, until the microemulsion is viscous, the reaction is completed, and fine wet gel particles are formed in the container. After aging by immersion in deionized water for 8 h, it was washed with deionized water to remove CTAB. The wet gel after suction filtration was replaced with alcohol and heptane as solvents for 4 hours respectively and dispersed for 30 minutes under ultrasonic wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com