Method for preparing monodispersed copper-protoxide hollow microsphere by aqueous phase cluster soft mold plates process

A technology of cuprous oxide and soft template method, which is applied in the direction of copper oxide/copper hydroxide, nanostructure manufacturing, nanotechnology, etc., can solve the problems of wide particle size distribution, poor structural stability, unfavorable mass production, etc., to achieve Convenient condition control, low cost, easy operation and repeatable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

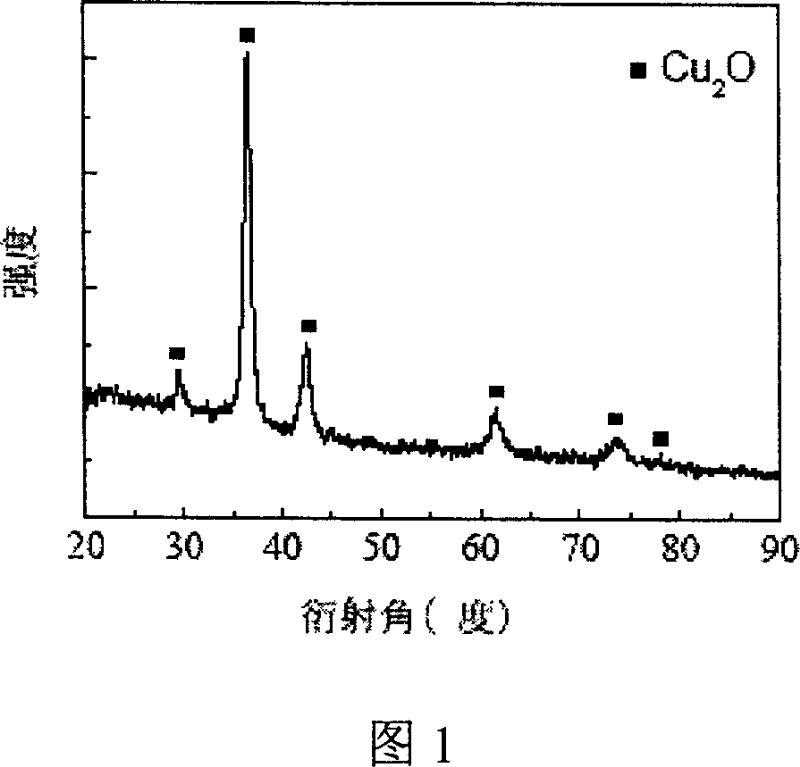

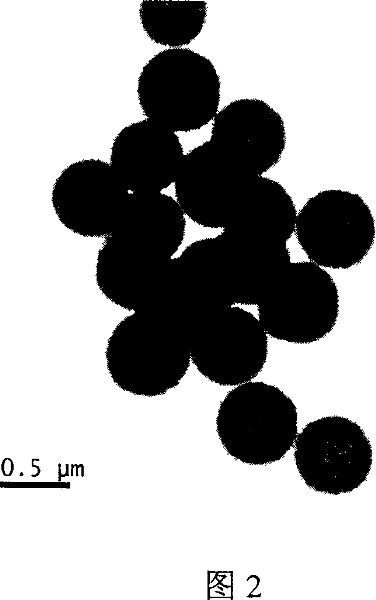

Embodiment 1

[0020] 1) Add a certain amount of polyvinylpyrrolidone and sodium lauryl sulfate into deionized water, heat to 40-60°C to fully dissolve and self-assemble into clusters, and mix with copper sulfate aqueous solution after the solution is cooled to room temperature , so that the final concentration of each component in the solution is respectively: copper sulfate 1mmol / L, polyvinylpyrrolidone 10g / L, sodium lauryl sulfate 9mmol / L;

[0021] 2) adjusting the pH value of the mixed solution obtained in step 1) with an aqueous sodium hydroxide solution to 8.5 to 11.5;

[0022] 3) During stirring, a 50% aqueous solution of hydrazine hydrate is added to the mixed solution obtained in step 2), and the molar ratio of copper sulfate to hydrazine hydrate is 1:20. After uniform mixing, stand still in a constant temperature water bath at 40-60°C to react for 55 minutes to obtain a colloidal solution containing monodisperse cuprous oxide hollow submicrospheres;

[0023] 4) Centrifuge the coll...

Embodiment 2

[0026] 1) Add a certain amount of polyvinylpyrrolidone and sodium lauryl sulfate into deionized water, heat to 40-60°C to fully dissolve and self-assemble into clusters, and mix with copper chloride aqueous solution after the solution is cooled to room temperature Mix so that the final concentration of each component in the solution is respectively: copper chloride 1mmol / L, polyvinylpyrrolidone 10g / L, sodium lauryl sulfate 35mmol / L;

[0027] 2) adjusting the pH value of the mixed solution obtained in step 1) with an aqueous sodium hydroxide solution to 8.5 to 11.5;

[0028] 3) During stirring, a 50% aqueous solution of hydrazine hydrate is added to the mixed solution obtained in step 2), and the molar ratio of copper sulfate to hydrazine hydrate is 1:20. After uniform mixing, stand still in a constant temperature water bath at 40-60°C to react for 55 minutes to obtain a colloidal solution containing monodisperse cuprous oxide hollow submicrospheres;

[0029] 4) Centrifuge the...

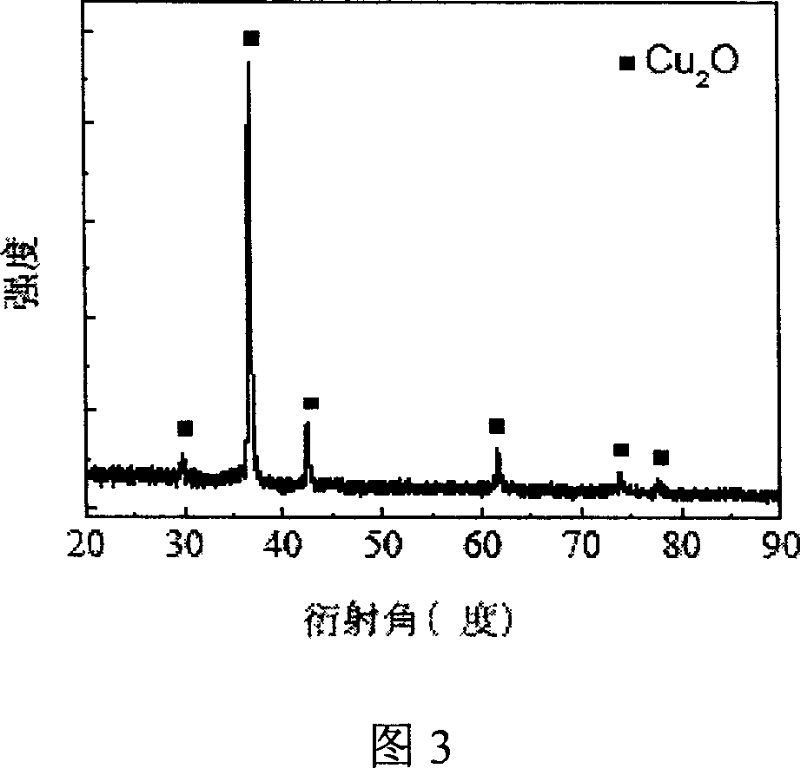

Embodiment 3

[0032] 1) Add a certain amount of polyvinylpyrrolidone and sodium lauryl sulfate into deionized water, heat to 40-60°C to fully dissolve and self-assemble into clusters, and mix with copper sulfate aqueous solution after the solution is cooled to room temperature , so that the final concentration of each component in the solution is respectively: copper sulfate 5mmol / L, polyvinylpyrrolidone 2g / L, sodium lauryl sulfate 9mmol / L;

[0033] 2) adjusting the pH value of the mixed solution obtained in step 1) with an aqueous sodium hydroxide solution to 8.5 to 11.5;

[0034] 3) During stirring, a 50% aqueous solution of hydrazine hydrate is added to the mixed solution obtained in step 2), and the molar ratio of copper sulfate to hydrazine hydrate is 1:20. After uniform mixing, stand still in a constant temperature water bath at 40-60°C to react for 55 minutes to obtain a colloidal solution containing monodisperse cuprous oxide hollow submicrospheres;

[0035] 4) Centrifuge the collo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com