Process for separating molybdenum from lead in high-lead molybdenum ore

A kind of ore and process technology, applied in the field of molybdenum-lead separation process of high-lead molybdenum ore, can solve the problems of deteriorating selection operation conditions, low hardness of galena, easy crushing, etc., to improve product quality, strengthen suppression effect, solve the problem of containing The effect of high lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

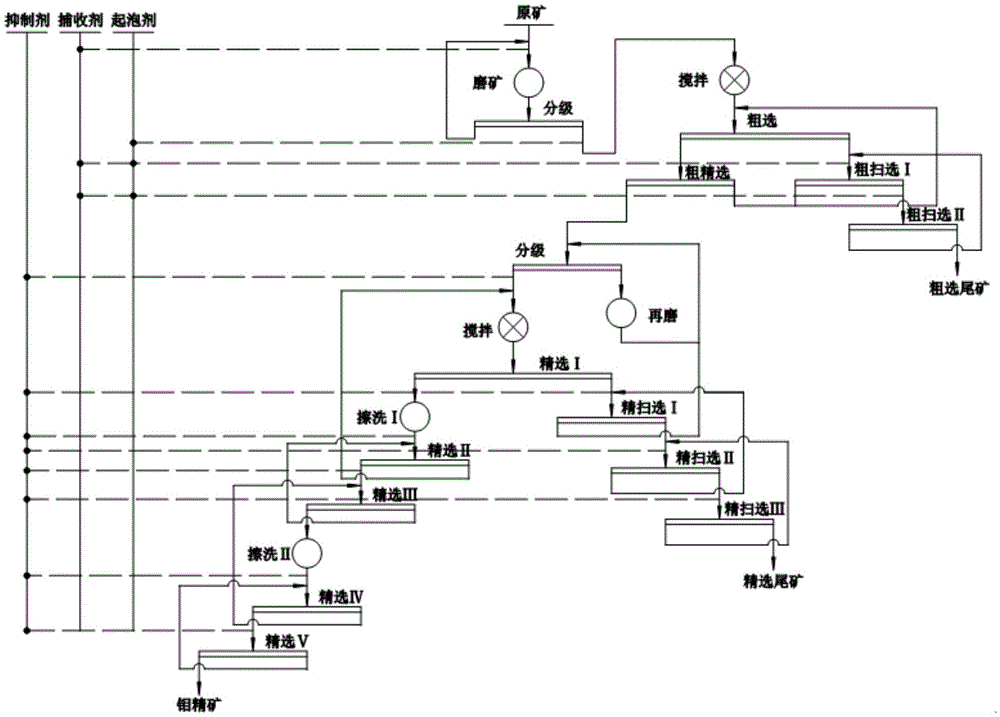

[0035] In this embodiment, the mass percent content of lead is 0.016% to carry out the separation of molybdenum and lead from molybdenum-lead molybdenum ore. The specific process and medicament system are as follows: Figure 4 As shown, it includes carrying out a stage of grading after the raw ore is subjected to a stage of grinding process, and also includes the following steps:

[0036] Step 1. Send a section of graded overflow into a flotation machine or a flotation column for roughing to obtain roughing foam and roughing tailings; add a phosphoknox inhibitor to the roughing, and the dosage of the phosphoknox inhibitor is 8g / t raw ore;

[0037] Step 2, send the roughing tailings described in step 1 into the flotation machine and carry out rough sweeping for the first time, obtain the first rough sweep tailings and the first rough sweep foam, and the first rough sweep Foam returns to step 1; the amount of frother used in the first rough sweep is 2.3g / t raw ore;

[0038] St...

Embodiment 2

[0043] In this embodiment, the mass percent content of lead is 0.020% for the high-lead molybdenum ore to carry out molybdenum-lead separation. The specific process and medicament system are as follows: Figure 4 As shown, it includes carrying out a stage of grading after the raw ore is subjected to a stage of grinding process, and also includes the following steps:

[0044] Step 1. Send a section of graded overflow into a flotation machine or a flotation column for roughing to obtain roughing foam and roughing tailings; add a phosphoknox inhibitor to the roughing, and the dosage of the phosphoknox inhibitor is 12g / t raw ore;

[0045] Step 2, send the roughing tailings described in step 1 into the flotation machine and carry out rough sweeping for the first time, obtain the first rough sweep tailings and the first rough sweep foam, and the first rough sweep Foam returns to step 1; the amount of frother used in the first rough sweep is 1.9g / t raw ore;

[0046] Step 3, sending...

Embodiment 3

[0051] The present embodiment carries out molybdenum-lead separation to the high-lead molybdenum ore that the mass percent content of lead is 0.038%, and specific process and medicament system are as follows Figure 4 As shown, it includes carrying out a stage of grading after the raw ore is subjected to a stage of grinding process, and also includes the following steps:

[0052] Step 1. Send a section of graded overflow into a flotation machine or a flotation column for roughing to obtain roughing foam and roughing tailings; add a phosphoknox inhibitor to the roughing, and the dosage of the phosphoknox inhibitor is 20g / t raw ore;

[0053] Step 2, send the roughing tailings described in step 1 into the flotation machine and carry out rough sweeping for the first time, obtain the first rough sweep tailings and the first rough sweep foam, and the first rough sweep Foam returns to step 1; the amount of frother used in the first rough sweep is 1.5g / t raw ore;

[0054] Step 3, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com