Preparation method of calcined kaolin with high oil absorption

A technology of calcined kaolin and high oil absorption, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as not easy to disperse, equipment corrosion, and product sieve residue exceeding the standard, and achieve easy dispersion and non-corrosiveness The effect of viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

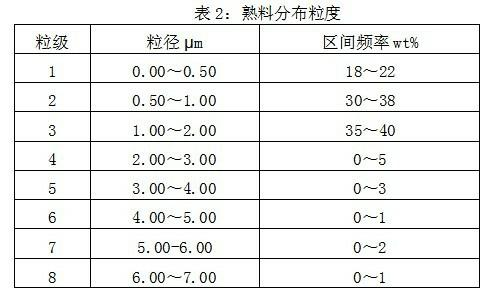

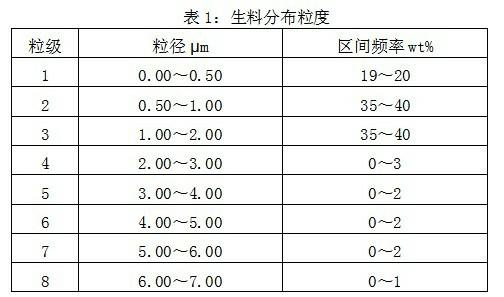

[0021] Embodiment 1-3: The preparation method of the high oil absorption calcined kaolin adopts the following process.

[0022] Coal series kaolinite is screened, ore washed, crushed, milled, stripped, and spray-dried to form raw meal. The raw meal is depolymerized and dispersed, then calcined into clinker, and finally the clinker is depolymerized and dispersed to obtain calcined Kaolin.

[0023] 1. Raw ore ratio: Shanxi Hunyuan Coal Measures Kaolinite 40~50wt%, Shanxi Huairen Coal Measures Kaolinite 30~40wt%, Shanxi Tashan Coal Measures Kaolinite 10~30wt%;

[0024] According to the composition content of each raw ore, it is configured into the following three weight ratios of coal-measure kaolinite ore blending:

[0025] (1) SiO 2 : 44.5%; Al 2 o 3 : 39.5%; Fe 2 o 3 : 0.1%; TiO 2 : 0.9%; LOI: 15%.

[0026] (2) SiO 2 : 45.8%; Al 2 o 3 : 37%; Fe 2 o 3 : 0.2%; TiO 2 : 1.0%; LOI: 16%.

[0027] (3) SiO 2 : 46.5%; Al 2 o 3 : 38.15%; Fe 2 o 3 : 0.25%; TiO 2 : 1....

Embodiment 4-6

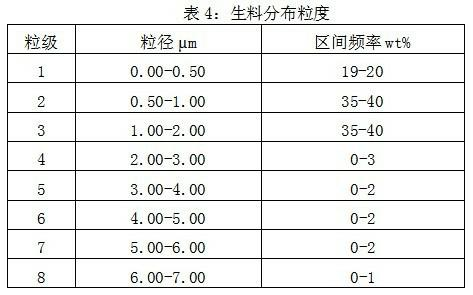

[0049] Embodiment 4-6: The preparation method of the high oil absorption calcined kaolin adopts the following process.

[0050] The kaolin is screened, ore washed, crushed, milled, stripped, and spray-dried to form a raw meal. The raw meal is depolymerized and dispersed, and then the clinker is calcined. Finally, the clinker is depolymerized and dispersed to obtain calcined kaolin.

[0051] 1. Raw ore ratio: Maoming kaolin 60-80wt%, Longyan kaolin 20-40wt%

[0052] According to the composition content of each raw ore, it is configured into the following three kinds of kaolin ore blending ratios by weight:

[0053] (1) SiO 2 : 44.5%; Al 2 o 3 : 39%; Fe 2 o 3 : 0.2%; TiO 2 : 1.1%; LOI: 15.2%.

[0054] (2) SiO 2 : 45.5%; Al 2 o 3 : 39.5%; Fe 2 o 3 : 0.2%; TiO 2 : 0.8%; LOI: 14%.

[0055] (3) SiO 2 : 46.5%; Al 2 o 3 : 37%; Fe 2 o 3 : 0.1%; TiO 2 : 0.4%; LOI: 16%.

[0056] 2. Raw meal depolymerization and breaking up parameters

[0057] Current: 150-170A

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com