Shape-controllable nano lithium titanate composite and preparation method thereof and lithium ion battery

A nano-lithium titanate and composite material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as insufficient rate performance and cycle performance of lithium-ion batteries, improve stability and conductivity, and inhibit flatulence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]According to the ratio of Li:(Ti+M) substance amount is 0.82:(0.95+0.05), respectively weigh lithium hydroxide 30.00g, titanium dioxide 116.66g, zirconia 9.39g and dispersion medium deionized water 150ml and fully Mix for 4 hours and sinter at 800°C for 20 hours to obtain a lithium titanate composite material precursor with the molecular formula Li 4 Ti 4.95 Zr 0.05 o 12 . Weigh 100g of the crushed lithium titanate composite precursor and add it to 400g of deionized water to form a slurry. At the same time, add zirconium hydroxide according to n(Zr):n(precursor)=0.01, and add zirconium hydroxide according to m(carbon):m (Precursor) = 0.015 Add citric acid and grind in a sand mill until D50 is 250nm. The resulting final slurry was spray dried with an inlet temperature of 300°C. Under the protection of hydrogen, it was sintered at 800°C for 5h to obtain a nano-lithium titanate composite material coated with carbon and zirconia.

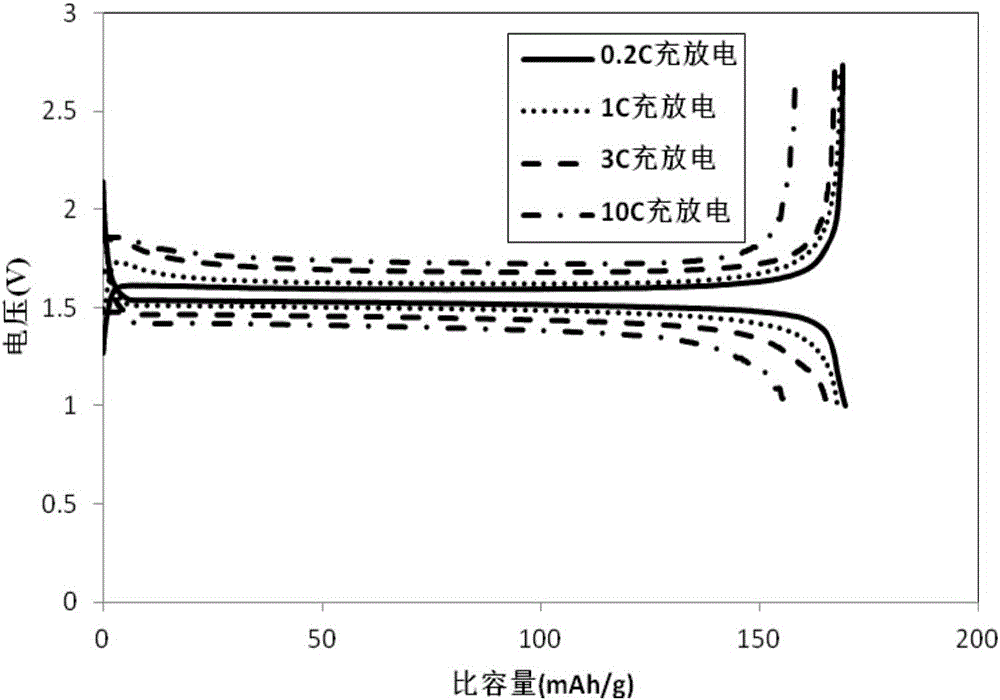

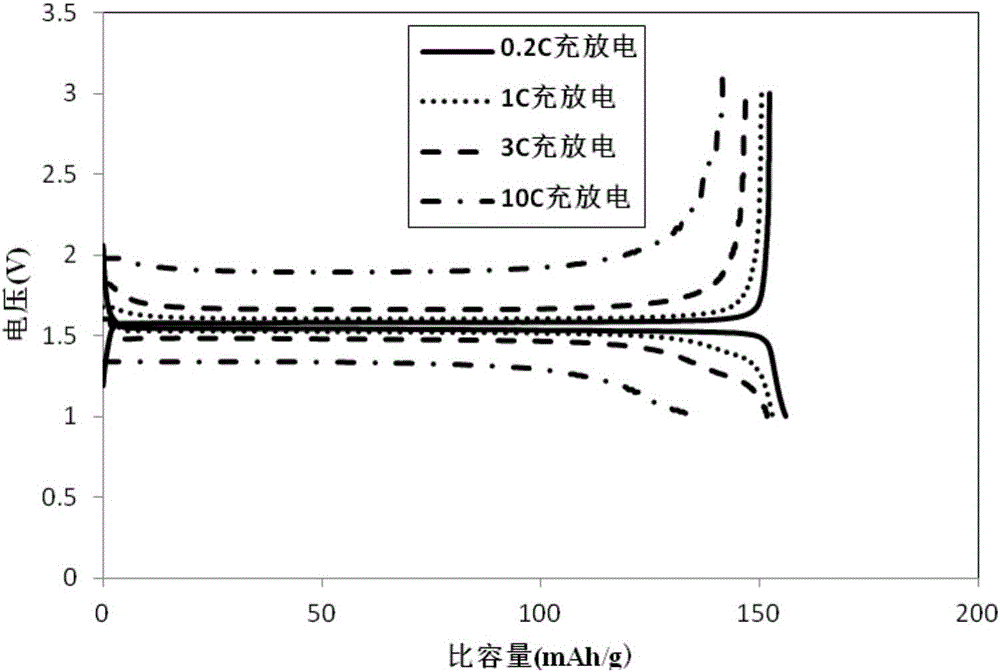

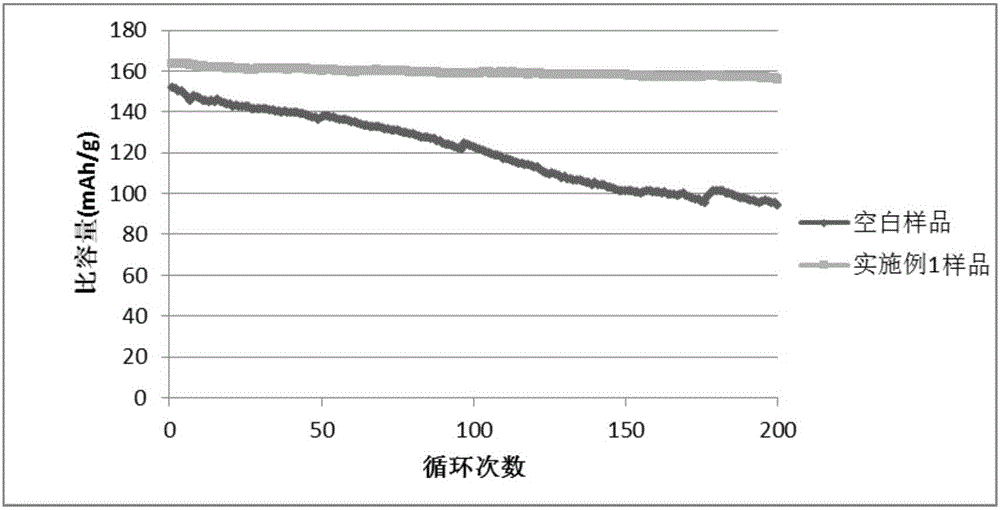

[0039] After testing, the particle si...

Embodiment 2

[0042] According to the ratio of Li:(Ti+M) substance amount is 0.82:(0.92+0.08), respectively weigh 60.00g of lithium oxalate, 67.43g of metatitanic acid, 7.60g of molybdenum dioxide and 150ml of methanol as a dispersion medium and fully Mix for 2 hours and sinter at 850°C for 15 hours to obtain a lithium titanate composite material precursor with the molecular formula Li 4 Ti 4.92 Mo 0.08 o 12 . Weigh 100g of the crushed lithium titanate composite material precursor and add it to 300g of ethanol, configure it into a slurry, and add alumina according to n(Al):n(precursor)=0.025, and add according to m(carbon):m (Precursor) = 0.15 Add sucrose and grind in a sand mill until D50 is 150nm. The resulting final slurry was subjected to dynamic vacuum drying at a drying temperature of 70 °C. In methane atmosphere, sintering at 700°C for 8h, to obtain nano-lithium titanate composite material coated with carbon and aluminum oxide.

[0043] After testing, the particle size D50 of t...

Embodiment 3

[0046] According to the ratio of Li:(Ti+M) substance amount is 0.85:(0.94+0.06), respectively weigh 40.00g of lithium carbonate, 95.09g of titanium dioxide, 3.85g of aluminum oxide and 150ml of deionized water and mix them fully in a ball mill for 2h, Sintering at 1000°C for 2 hours to obtain the precursor of lithium titanate composite material, the molecular formula is Li 4 Ti 4.94 Al 0.06 o 12 . Weigh 100g of the crushed lithium titanate composite material precursor and add it to 300g deionized water to form a slurry, and add molybdenum dioxide according to n(Mo):n(precursor)=0.04, and according to m(carbon): m (precursor) = 0.2 Add citric acid and grind in a sand mill until D50 is 350nm. The resulting final slurry was spray dried with an inlet temperature of 300°C. Sintering at 500° C. for 10 h in an air atmosphere to obtain a molybdenum dioxide-coated nano-lithium titanate composite material.

[0047] After testing, the particle size D50 of the nano-lithium titanate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com