Preparation method of LED (light emitting diode) chip compounding-special conducting adhesive

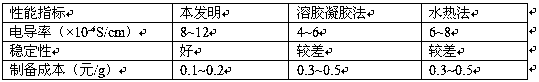

A technology of LED chips and conductive adhesives, applied in the direction of conductive adhesives, adhesives, adhesive additives, etc., can solve the problems of poor conductivity and stability, lack of chemical modification technology, and large resource consumption, and achieve stability and Improved electrical conductivity, simple process, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

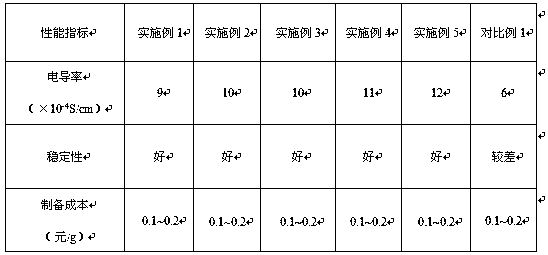

Examples

Embodiment 1

[0040] The weight parts of the raw material components of the composite conductive adhesive are:

[0041] 88 parts of thiophene, 5 parts of epoxy acrylic resin, 0.5 parts of silane coupling agent, 8 parts of trimethyl hydroxyethyl ammonium chloride, 0.5 parts of catalyst, 3 parts of copper sulfate pentahydrate; Ethoxysilane; the catalyst is nickel chloride;

[0042] The preparation process of composite conductive adhesive is as follows:

[0043](1) Dissolve thiophene in petroleum ether, use petroleum ether as eluent, pass through a silica gel chromatography column, and then rotary evaporate to remove petroleum ether, add the obtained purified thiophene to an aqueous solution of ethanol, and add a silane coupling agent, slowly Ultrasonic dispersion is carried out while stirring; in the aqueous ethanol solution, the mass concentration of ethanol is 50%; the addition amount of the aqueous ethanol solution is 3 times the mass of thiophene; the ultrasonic dispersion adopts an ultr...

Embodiment 2

[0048] The weight parts of the raw material components of the composite conductive adhesive are:

[0049] 85 parts of thiophene, 10 parts of epoxy acrylic resin, 1 part of silane coupling agent, 9 parts of trimethyl hydroxyethyl ammonium chloride, 1 part of catalyst, 4 parts of copper sulfate pentahydrate; the silane coupling agent is vinyl trimethoxy base silane; catalyst is zinc chloride;

[0050] The preparation process of composite conductive adhesive is as follows:

[0051] (1) Dissolve thiophene in petroleum ether, use petroleum ether as eluent, pass through a silica gel chromatography column, and then rotary evaporate to remove petroleum ether, add the obtained purified thiophene to an aqueous solution of ethanol, and add a silane coupling agent, slowly Ultrasonic dispersion is carried out while stirring; in the ethanol aqueous solution, the mass concentration of ethanol is 40%; the addition amount of the ethanol aqueous solution is 4 times the mass of thiophene; ultra...

Embodiment 3

[0056] The weight parts of the raw material components of the composite conductive adhesive are:

[0057] 88 parts of thiophene, 8 parts of epoxy acrylic resin, 0.8 parts of silane coupling agent, 8 parts of trimethyl hydroxyethyl ammonium chloride, 0.6 parts of catalyst, 2.6 parts of copper sulfate pentahydrate; the silane coupling agent is vinyl tri( Methoxyethoxy) silane; the catalyst is zinc powder;

[0058] The preparation process of composite conductive adhesive is as follows:

[0059] (1) Dissolve thiophene in petroleum ether, use petroleum ether as eluent, pass through a silica gel chromatography column, and then rotary evaporate to remove petroleum ether, add the obtained purified thiophene to an aqueous solution of ethanol, and add a silane coupling agent, slowly Ultrasonic dispersion is carried out while stirring; in the ethanol aqueous solution, the mass concentration of ethanol is 70%; the addition amount of the ethanol aqueous solution is twice the mass of thiop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com