Contact piece structure for vehicle-mounted cigarette lighter socket

A vehicle-mounted cigarette lighter and cigarette lighter technology, which is applied in the direction of vehicle connectors, contact parts, bases/shells, etc., can solve problems such as adverse effects of contact resistance, poor contact consistency, and limited flow performance, so as to improve stable battery life Capability and safety, conductivity and stability, and the effect of increasing the smoothness of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to illustrate the embodiments of the present application or the technical solutions in the prior art more clearly, the embodiments will be briefly introduced below.

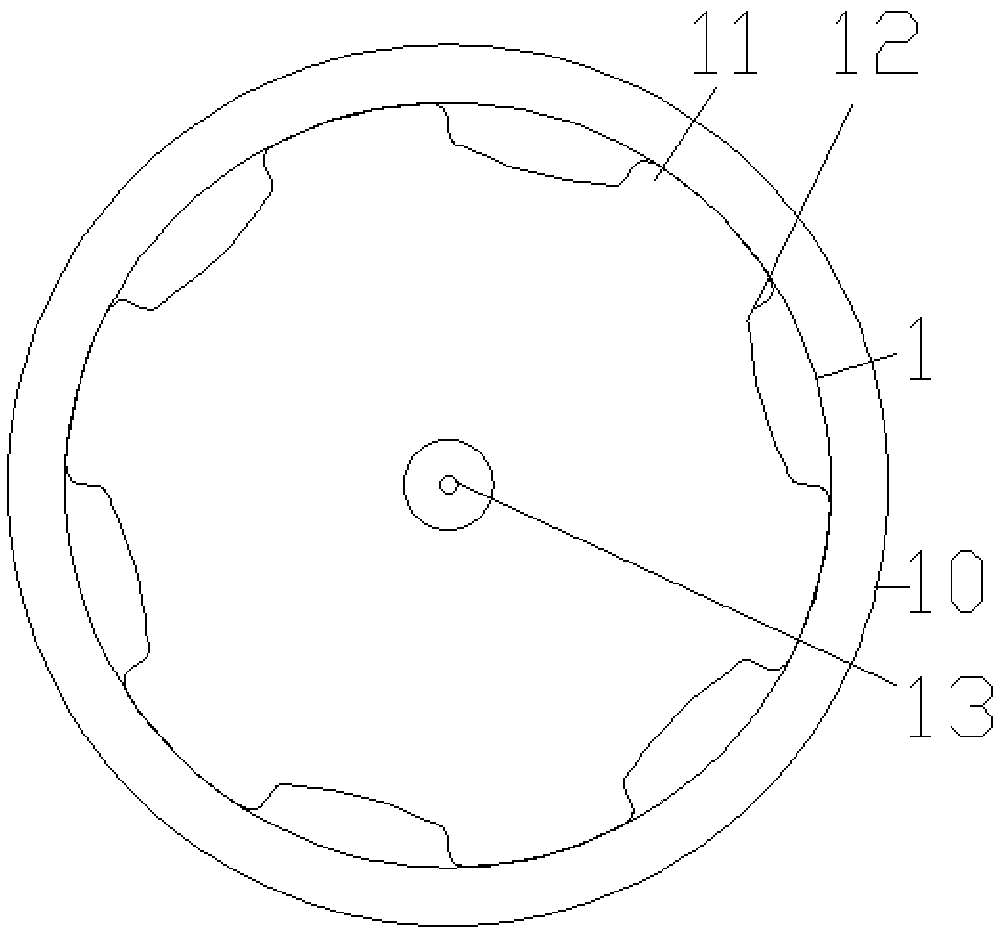

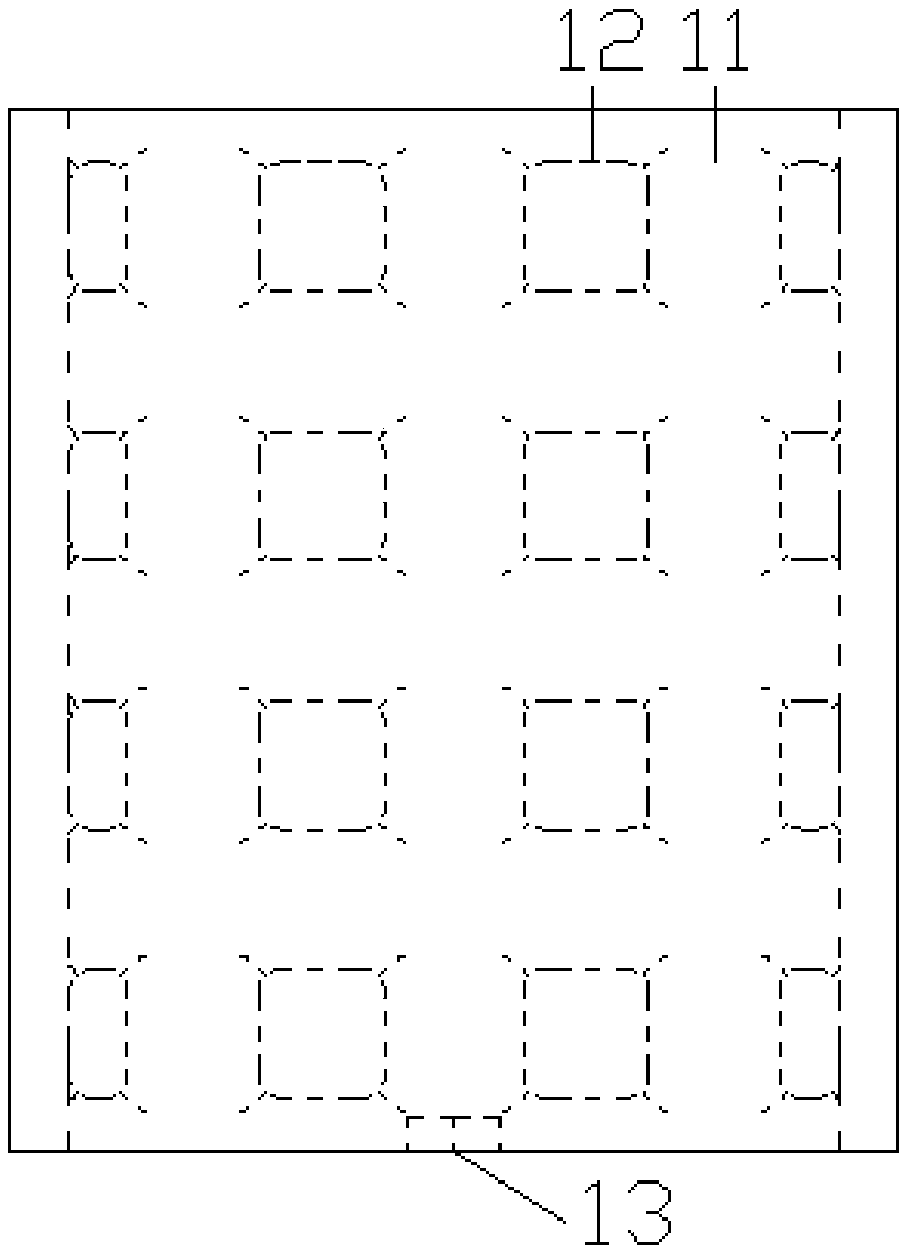

[0016] Such as Figure 1~2 , a contact piece structure for a vehicle-mounted cigarette lighter socket, the inner wall of the cigarette lighter socket 10 has a contact shell 1, the thickness of the contact shell 1 is 0.8~2.5mm, and the contact shell 1 includes concave parts 11 and convex parts arranged at regular intervals 12. The bottom of the cigarette lighter socket 10 has an intermediate pole 13 connected to the external plug; the concave parts 11 and the convex parts 12 are evenly distributed in 6~8 groups on the inner wall of the cigarette lighter socket 10, and evenly distributed in the vertical direction for 3~ 5 groups;

[0017] Both the concave portion 11 and the convex portion 12 are rounded rectangles, the concave portion 11 is one of a concave spherical surface, a paraboloid or a hype...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Horizontal width | aaaaa | aaaaa |

| Vertical width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com