Radial efficient powder selecting machine and design method of powder selecting machine

A design method and technology of a powder separator, which are applied in chemical instruments and methods, solid separation, and separation of solids from solids by airflow, which can solve the problem of increasing airflow resistance, increasing powder separation resistance loss, and increasing system power consumption. and other problems, to achieve the effect of high powder selection efficiency, low resistance, and wide gradation of finished particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

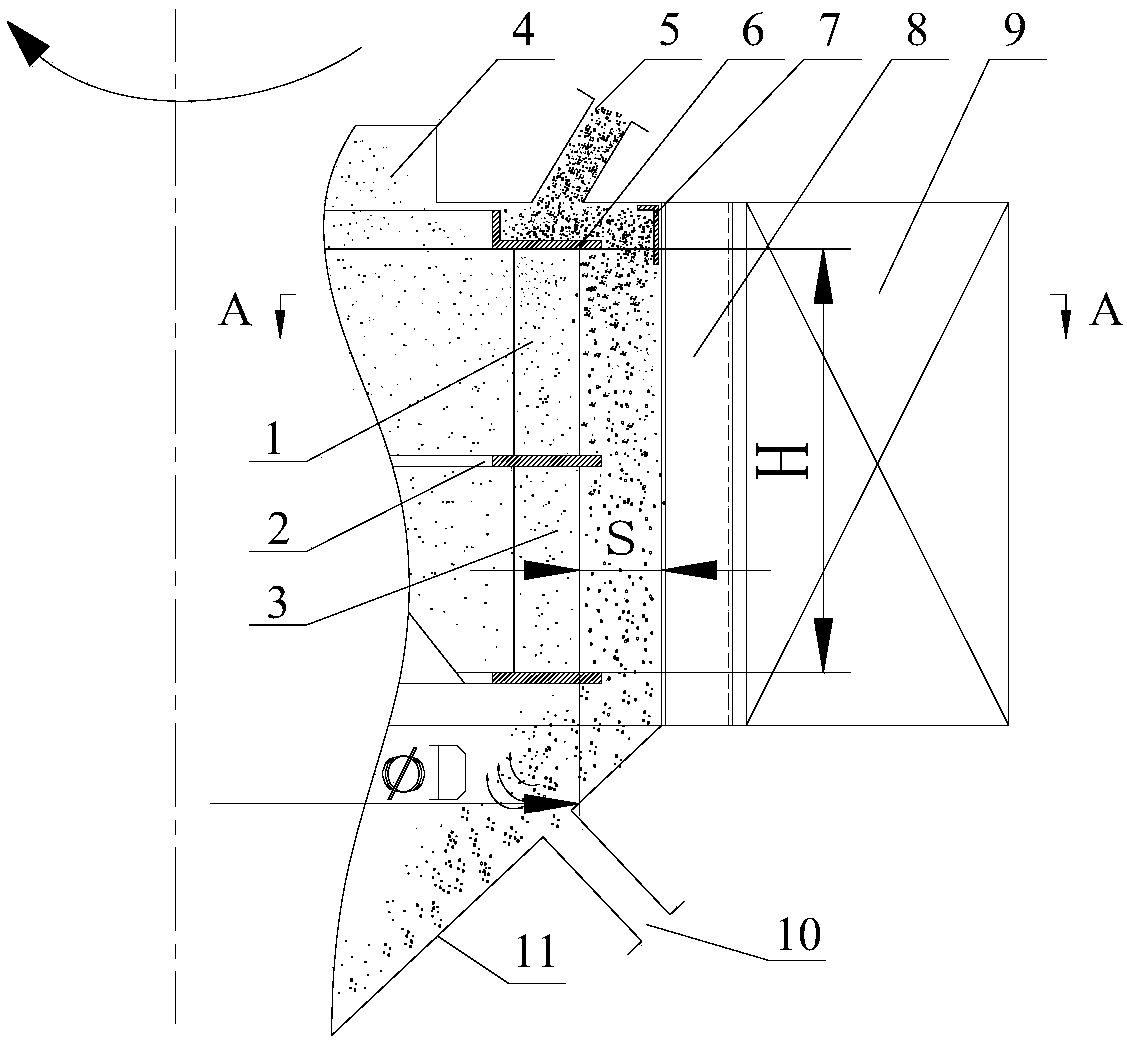

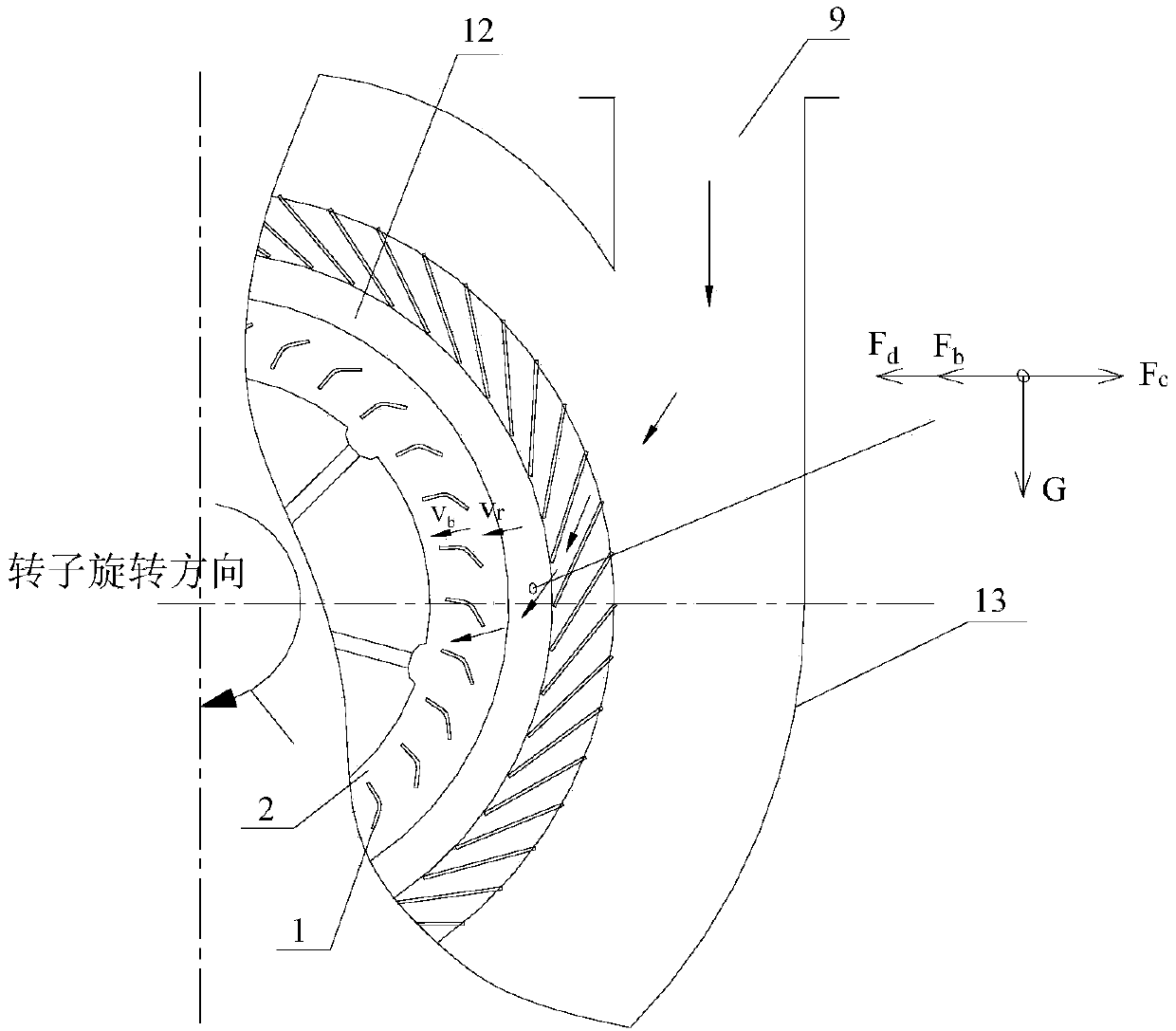

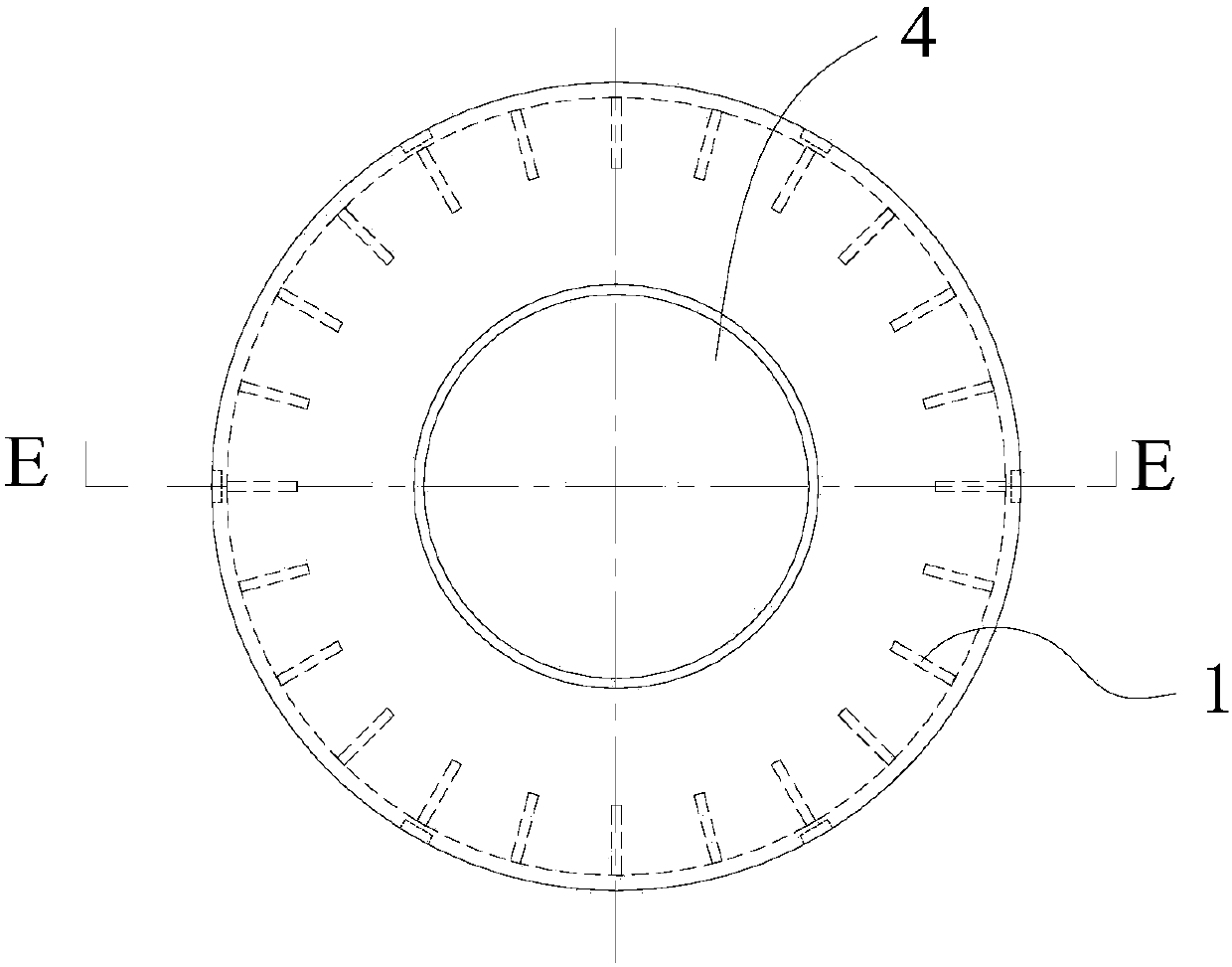

[0056] Example 1, see figure 1 and figure 2 , a centripetal high-efficiency powder separator, comprising a powder separator housing 13, a finished product outlet 4 arranged on the upper part of the powder separator; an air inlet connected to the powder separator casing and a feeding port 5 arranged on the upper part; corresponding to feeding There is a material spreading plate 6 in the shell of the powder separator at the position of the material opening, and a material buffer plate 7 is provided at the corresponding position of the material spreading plate. The coarse powder collecting cone 11 located at the lower end of the powder separator shell is provided with three times Air inlet 10; the powder separator rotor 2 installed in the powder separator housing is provided with the upper and lower moving blades of the powder separator rotor. The blades are named as two-stage moving blades 3, and stationary blades are installed on the powder separator housing corresponding to...

Embodiment 2

[0107] Example 2, see Figure 8 and Figure 9 , a centripetal high-efficiency powder separator, including a powder separator shell 13, a finished product outlet 4 arranged on the upper part of the powder separator; connecting the air inlet 9 and the feeding port 5 of the powder separator shell, this model belongs to The air inlet and the feeding port of the prior art are the same; the feeding port is on the side of the powder separator shell; the coarse powder collecting cone located at the lower end of the powder separator shell is provided with a tertiary air blower on the coarse powder collecting cone. Entrance 10; the powder separator rotor 2 installed in the powder separator housing, the upper and lower moving blades of the powder separator rotor are set, and the upper moving blade is named as a section of moving blade 1 for convenience of explanation, and the lower moving blade Named as the second-stage moving blade 3, the powder separator shell is equipped with a stati...

Embodiment 3

[0108] Example 3, see Figure 10 and Figure 11 , a centripetal high-efficiency powder separator, including a powder separator shell 13, a finished product outlet 4 arranged on the upper part of the powder separator; connecting the air inlet 9 and the feeding port 5 of the powder separator shell, this model belongs to The air inlet and the feeding port of the prior art are the same; the feeding port is at the lower end of the powder separator shell; the coarse powder collecting cone located at the lower end of the powder separator shell; The powder separator rotor 2 in the machine housing is provided with the upper and lower movable blades of the powder separator rotor. For the convenience of explanation, the upper movable blade is named as the first-stage movable blade 1, and the lower movable blade is named as the second-stage movable blade 3 , corresponding to the position of the moving blade, a static blade is installed on the shell of the powder selector; the moving blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com