Non-volatile memory element and preparation method thereof

A non-volatile storage and component technology, applied in the field of new micro-nano electronic functional devices, can solve the problem of insufficient resistance ratio, achieve the effects of good compactness, easy control of chemical composition, and improved signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

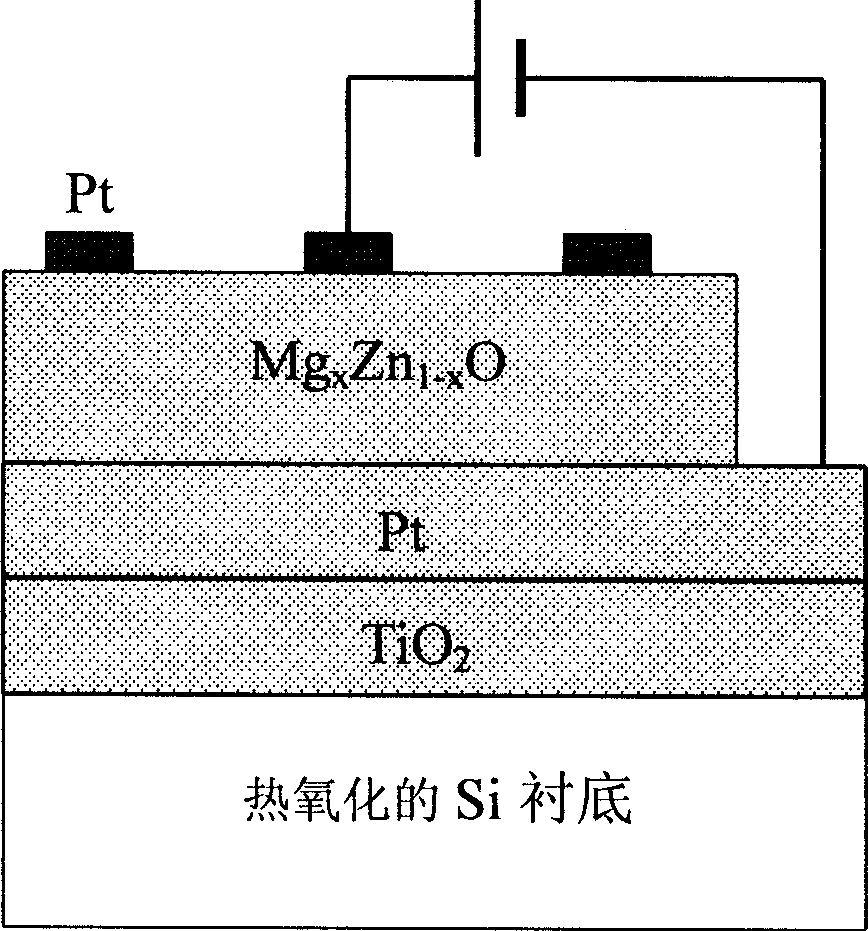

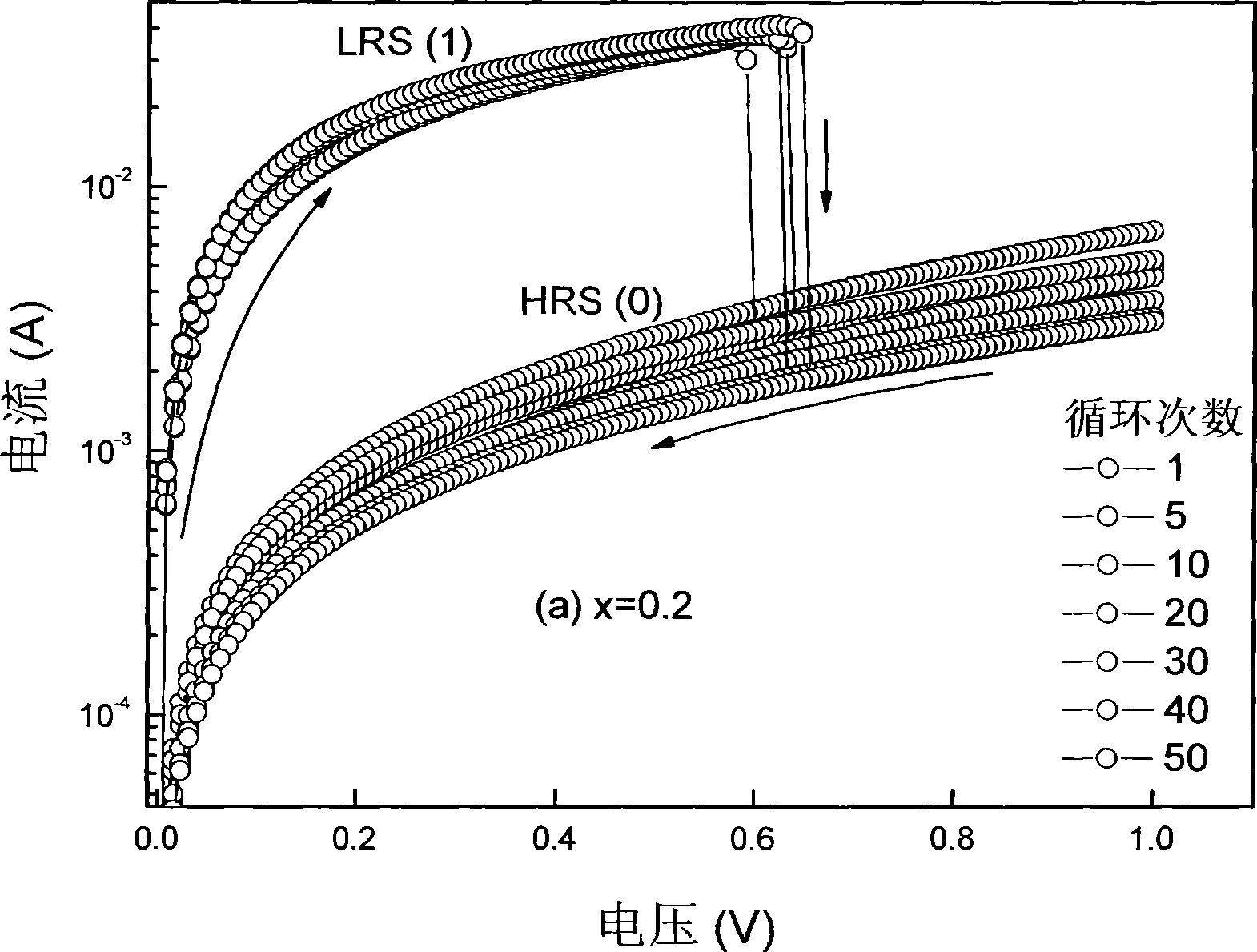

[0026] Embodiment 1 prepares Mg 0.2 Zn 0.8 O storage device

[0027] (1) Preparation of Mg 0.2 Zn 0.8 O precursor solution: Mix 0.8419g diethanolamine with ethylene glycol methyl ether, then add the required zinc acetate dihydrate and magnesium acetate tetrahydrate, heat to 120°C for 10min, cool to 80°C, keep the temperature for 2h, and cool to room temperature get Mg 0.2 Zn 0.8 O solution, the concentration was adjusted to 0.5mol / L, and the final solution volume was 20ml to obtain the precursor solution.

[0028] (2) Preparation of Mg 0.2 Zn 0.8 O thin film: the Mg 0.2 Zn 0.8 O precursor in clean Pt / TiO 2 / SiO 2 / Si substrate with spin-coating method to prepare thin film, the number of layers is six. The film flinging parameter is 2500 rpm, the time is 20 seconds, and the pretreatment temperature of each layer is 350° C., and the time is 5 minutes. Repeat the process of throwing film-pretreatment-removing film to obtain Mg 0.2 Zn 0.8 O film.

[0029] (3) the a...

Embodiment 2

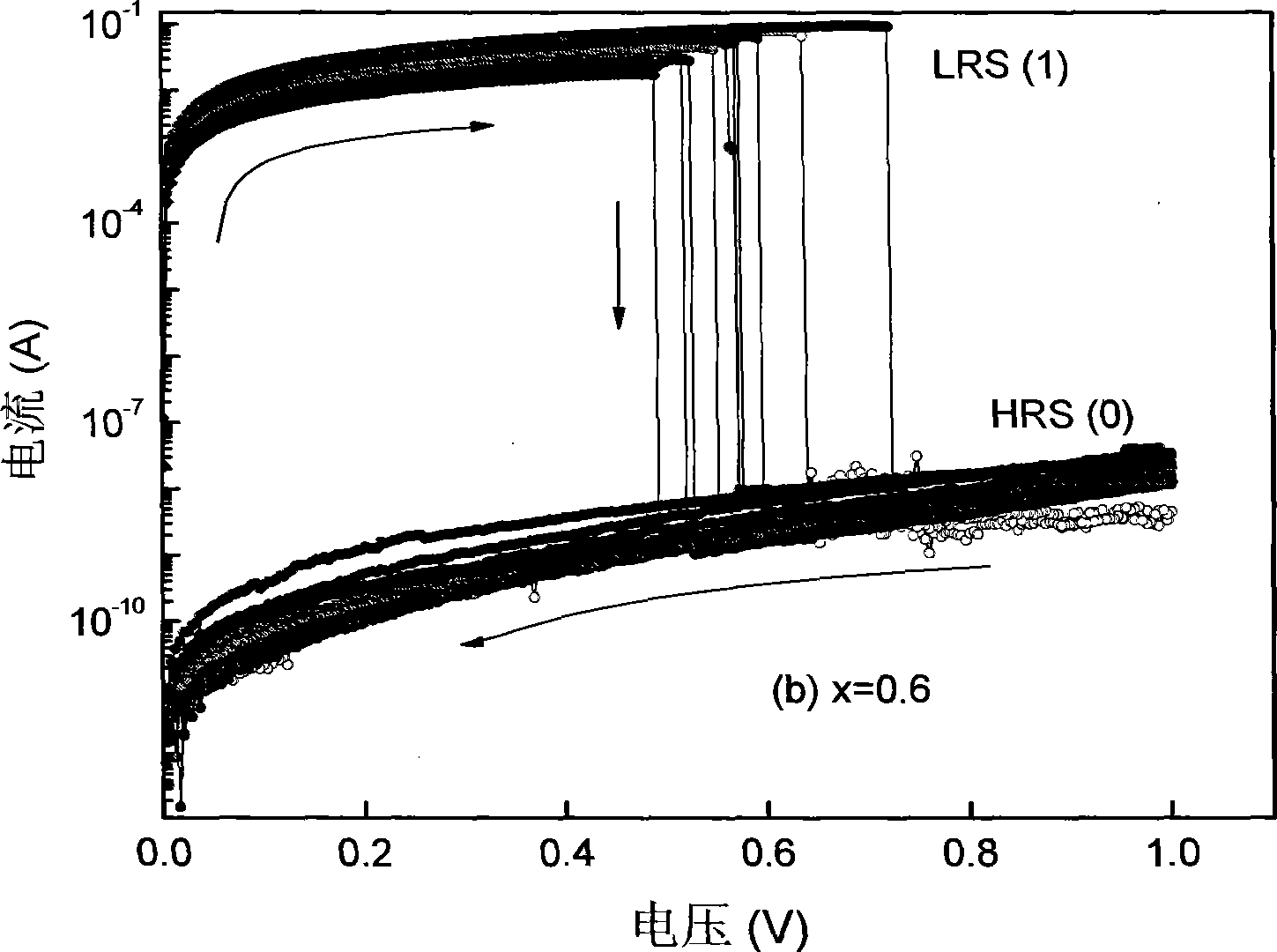

[0033] (1) Preparation of Mg 0.6 Zn 0.4 O solution: fully mix diethanolamine with the solvent, then add zinc acetate at room temperature, add magnesium acetate and mix evenly after dissolving, drop in 1ml of glacial acetic acid, stir at room temperature for 2 hours, then sonicate for 10 minutes, adjust the concentration, and obtain Mg 0.6 Zn 0.4 O precursor;

[0034] Mg 0.6 Zn 0.4 The preparation of O thin film and device is the same as (2), (3) and (4) of Example 1.

[0035] For device memory characteristics see image 3 , initialized with a 5mA current pulse for 50ms before the cyclic I-V curve test. The device can repeatedly switch between high and low resistance states, and the resistance ratio of high and low resistance states is greater than 10 7 .

Embodiment 3

[0037] (1)Mg 0.8 Zn0.2 O solution configuration: fully mix diethanolamine with the solvent, then add zinc acetate at room temperature, add magnesium acetate and mix evenly after dissolving (see Table 1), drop in 1ml of glacial acetic acid, stir at room temperature for 2h, then ultrasonicate for 10min, adjust Concentration, to obtain Mg for film preparation 0.8 Zn 0.2 O precursor;

[0038] Mg 0.8 Zn 0.2 The preparation of O thin film and device is the same as (2), (3) and (4) of Example 1.

[0039] The device memory characteristics are similar to (5) of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com