Method for preparing lanthanide series rare earth ions doped with bismuth titanate non-plumbum ferroelectric nano-wire

A technology of ion doping and lanthanide rare earth, which is applied in the field of preparation of lanthanide rare earth ion-doped bismuth titanate lead-free ferroelectric nanowire material, can solve the problems of complex operation process, high pressure of catalyst, long preparation cycle, etc., and achieve The effect of simple technical process, easy control and good market prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

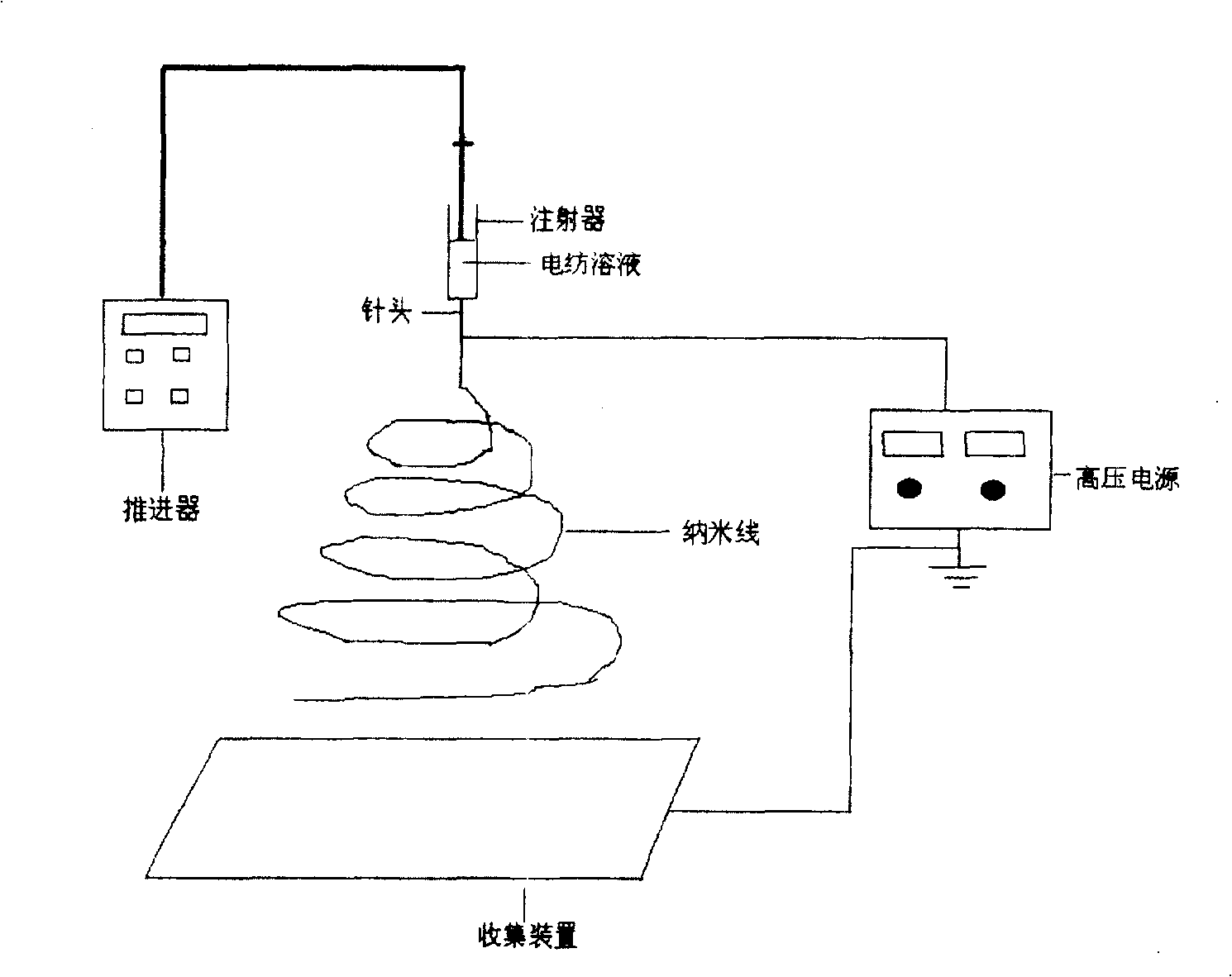

Method used

Image

Examples

Embodiment 1

[0035]With electronic balance, according to the molar ratio of Bi and Nd is 3.15: 0.85, take by weighing bismuth nitrate (excessive 10%) and neodymium nitrate 1.6978g and 0.3865g respectively, then add glacial acetic acid as solvent and carry out magnetic stirring, its mixture is mixed at normal temperature Completely dissolve to obtain solution A; according to the molar ratio of bismuth, neodymium and titanium is 3.15:0.85:3, weigh 1.0419g of tetrabutyl titanate and put it into another container, then add an appropriate amount of acetylacetone as a stabilizer, and then add solvent Glacial acetic acid, stirred for a while to obtain solution B; while stirring solution A with a magnetic stirrer, slowly add solution B to solution A dropwise, then dilute it with glacial acetic acid, and continue stirring for 1 hour to obtain a 0.05mol / L solution 20ml, after standing for 3 days, filter to get clear and transparent orange-yellow Bi 3.15 Nd 0.85 Ti 2 o 12 solution. Weigh 0.06g of...

Embodiment 2

[0037] Bi 3.15 Nd 0.85 Ti 3 o 12 The preparation process of the solution is the same as in Example 1. Weigh 0.2g of polyvinylpyrrolidone (PVP, Mw=630,000), dissolve it in 1ml of dichloromethane, magnetically stir at room temperature for 40min until completely dissolved, and prepare a 13.1% polyvinylpyrrolidone solution by mass ratio. Using acetylacetone as a stabilizer, take 1ml of Bi 3.15 Nd 0.85 Ti 3 o 12 The solution was added to the above-mentioned polyvinylpyrrolidone solution, and subjected to vigorous magnetic stirring at room temperature for 3 hours until the solution was completely uniformly mixed to obtain an orange-yellow transparent viscous solution, which was used as an electrospinning precursor solution for preparing nanowires. Put the above-mentioned electrospinning precursor solution into a plastic syringe, install a stainless steel needle and connect it to the positive electrode, the inner diameter of the needle is 0.5mm, adjust and control the voltage ...

Embodiment 3

[0039] With an electronic balance, according to the molar ratio of Bi and Nd is 3.54:0.46, respectively weigh bismuth nitrate (10% excess) and neodymium nitrate 1.9079g and 0.2092g, then add glacial acetic acid as solvent and carry out magnetic stirring, and its mixture is mixed at normal temperature Completely dissolve to obtain solution A; according to the molar ratio of bismuth, neodymium and titanium is 3.54:0.46:3, weigh 1.0419g of tetrabutyl titanate and put it into another container, then add an appropriate amount of acetylacetone as a stabilizer, and then add solvent Glacial acetic acid, stirred for a while to obtain solution B; while stirring solution A with a magnetic stirrer, slowly add solution B to solution A dropwise, then dilute it with glacial acetic acid, and continue stirring for 1 hour to obtain a 0.05mol / L solution 20ml, after standing for 7 days, filter to get clear and transparent orange-yellow Bi 3.54 Nd 0.46 Ti 3 o 12 solution. Weigh 0.06g of polyvi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com