Flicker glass of silicate activated by terbium, and preparation method

A technology of scintillation glass and silicate, which is applied in glass manufacturing equipment, glass pressing, glass molding, etc., can solve the problems that the sensitivity of X-ray imaging has not been well developed, and achieve easy-to-large size, chemical composition Easy to adjust, good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A terbium-activated silicate scintillation glass, with silicate as the matrix, is characterized in that: the scintillation glass introduces Tb 3+ is the active ion, Gd 3+ As a sensitizer, BaF 2 As a flux, it is prepared by melting method, and it is formed by shaping and annealing.

[0045] 1. Preparation process

[0046] The first step: formula (by mole percentage):

[0047] SiO 2 69.18mol%

[0048] BaO 16.67mol%

[0049] BaF 2 4.17mol%

[0050] Na 2O 1.91mol%

[0051] K 2 O 1.81mol%

[0052] Li 2 O 2.38mol%

[0053] al 2 o 3 0.87mol%

[0054] Tb 2 o 3 1.46mol%

[0055] Gd 2 o 3 1.56mol%

[0056] Step 2: Mix the formula thoroughly and melt it at 1400-1450°C for 3-6 hours by melting method;

[0057] The third step: Pour the prepared glass liquid into the preheated mold and shape it;

[0058] The fourth step: annealing treatment in the muffle furnace, at 600 ° C for 3 hours.

[0059] 2. Test

[0060] The prepared glass...

Embodiment 2

[0064] Others are all the same as Example 1, but the formula in the preparation process is different.

[0065] Formula (by mole percentage):

[0066] SiO 2 69.18mol%

[0067] BaO 16.67mol%

[0068] BaF 2 4.17mol%

[0069] Na 2 O 1.91mol%

[0070] K 2 O 1.80mol%

[0071] Li 2 O 2.38mol%

[0072] al 2 o 3 0.87mol%

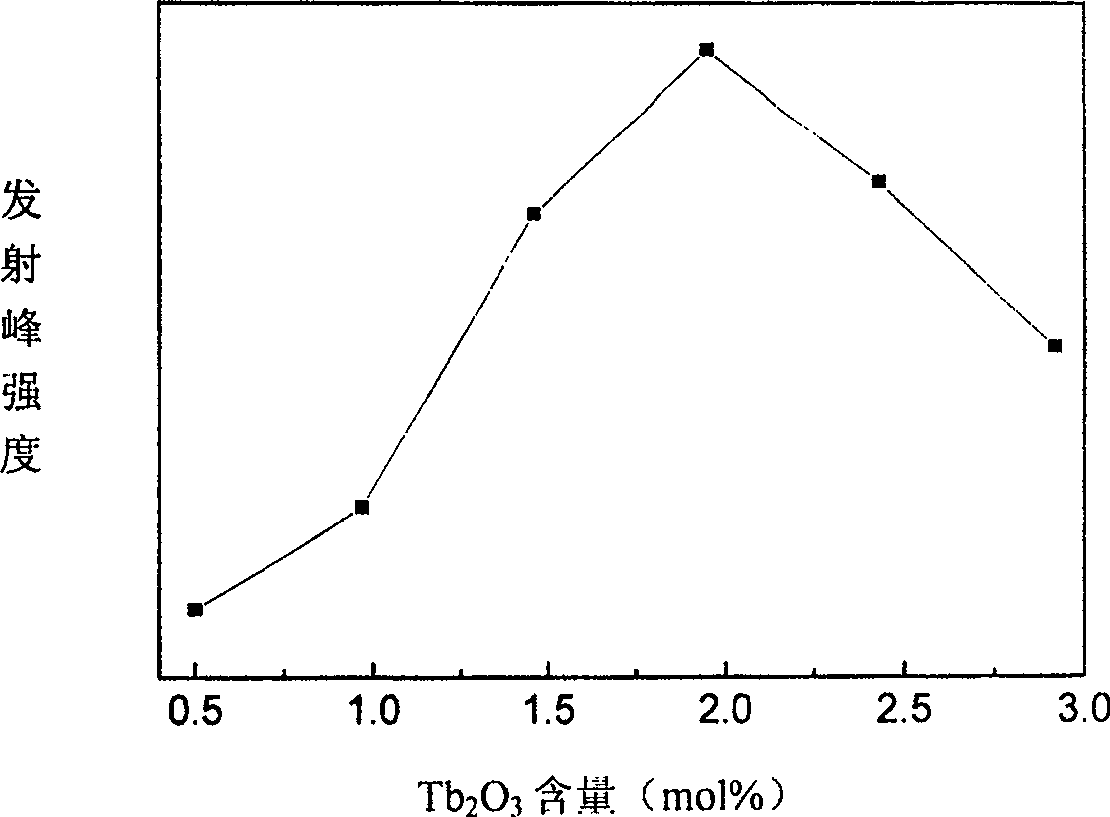

[0073] Tb 2 o 3 1.95mol%

[0074] Gd 2 o 3 1.07mol%

[0075] The emission peak intensity of the terbium-activated silicate scintillation glass prepared by this formula is close to the highest value.

Embodiment 3

[0077] Others are all the same as Example 1, but the formula in the preparation process is different.

[0078] Formula (by mole percentage):

[0079] SiO 2 69.19mol%

[0080] BaO 16.67mol%

[0081] BaF 2 4.17mol%

[0082] Na 2 O 1.91mol%

[0083] K 2 O 1.80mol%

[0084] Li 2 O 2.38mol%

[0085] al 2 o 3 0.87mol%

[0086] Tb 2 o 3 2.43mol%

[0087] Gd 2 o 3 0.58mol%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com