High-luminous-intensity terbium-activated silicate glass and preparation method thereof

A silicate glass and luminous intensity technology, applied in the field of high luminous intensity terbium-activated silicate glass and its preparation, can solve the problems of high defect state density, unsatisfactory energy transfer efficiency between ions, etc., and achieve enhanced luminescence The effect of strength, simple preparation process and easy adjustment of chemical composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] One, the preparation method of the terbium-activated silicate glass of high luminous intensity comprises the following steps:

[0069] The first step: formula (by mass percentage)

[0070] SiO 2 45.3%

[0071] al 2 o 3 1.5%

[0072] B 2 o 3 3.0%

[0073] BaO 9.9 %

[0074] Cs 2 O 9.9 %

[0075] Na 2 O 2.8 %

[0076] Li 2 O 2.0 %

[0077] K 2 O 1.3 %

[0078] Gd 2 o 3 9.0%

[0079] Tb 4 o 7 15.3%;

[0080] Step 2: After fully mixing the above formula evenly, melt it in the air atmosphere at 1500-1550 ℃ for 3-5 hours by melting method to obtain molten glass;

[0081] Step 3: Pour the molten glass into the preheated mold to shape it;

[0082] Step 4: heat preservation at 500-650° C. for 2-4 hours in a muffle furnace for annealing treatment.

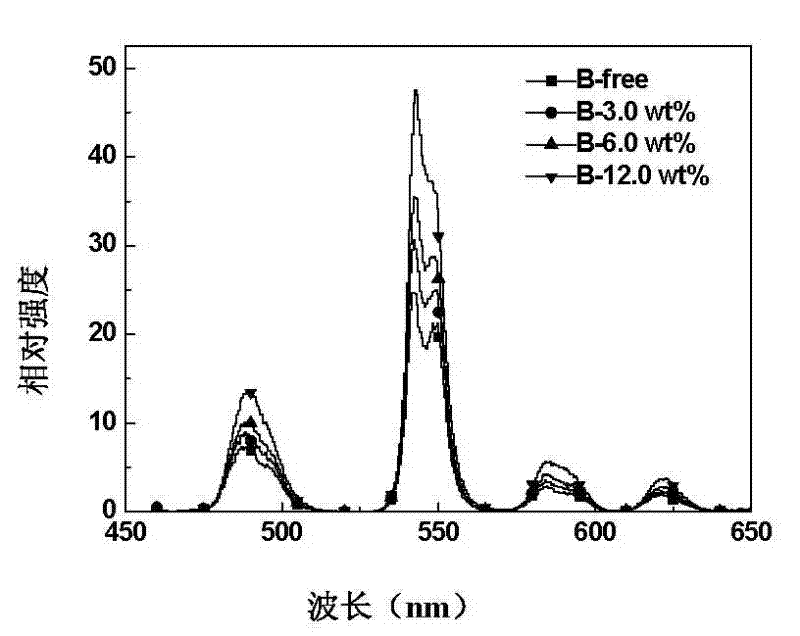

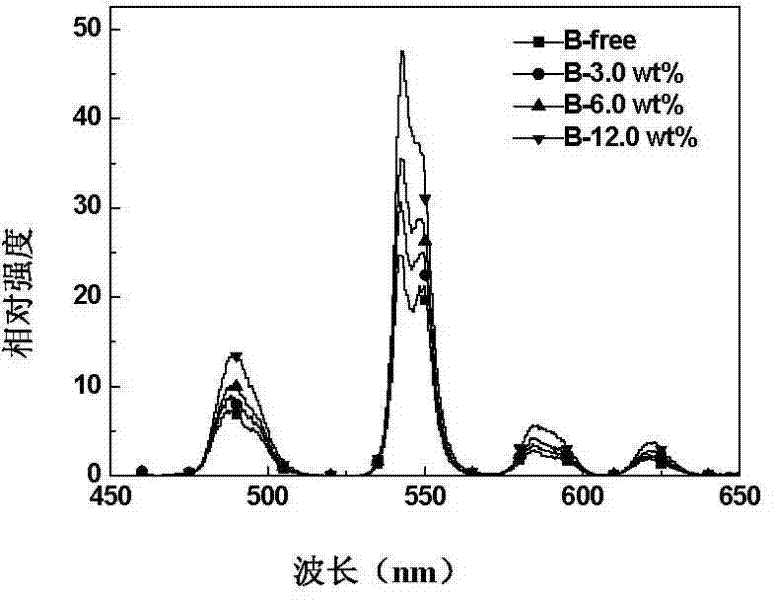

[0083] 2. Test

[0084] Cut the prepared glass into 25 mm×10 mm×5 mm samples, and test the ultraviolet ...

Embodiment 2

[0088] The preparation method is the same as in Example 1, except that the glass formulation is different.

[0089] Formula comprises by mass percentage:

[0090] SiO 2 42.3%

[0091] al 2 o 3 1.5%

[0092] B 2 o 3 6.0%

[0093] BaO 9.9 %

[0094] Cs 2 O 9.9 %

[0095] Na 2 O 2.8 %

[0096] Li 2 O 2.0 %

[0097] K 2 O 1.3 %

[0098] Gd 2 o 3 9.0%

[0099] Tb 4 o 7 15.3%.

[0100] Cut the prepared glass into 25 mm×10 mm×5 mm samples, and test the ultraviolet excitation emission spectrum after polishing (such as figure 1 Middle—▲—shown in the curve).

Embodiment 3

[0102] The preparation method is the same as in Example 1, except that the glass formulation is different.

[0103] Formula comprises by mass percentage:

[0104] SiO 2 36.3%

[0105] al 2 o 3 1.5%

[0106] B 2 o 3 12.0%

[0107] BaO 9.9 %

[0108] Cs 2 O 9.9 %

[0109] Na 2 O 2.8 %

[0110] Li 2 O 2.0 %

[0111] K 2 O 1.3 %

[0112] Gd 2 o 3 9.0%

[0113] Tb 4 o 7 15.3%.

[0114] Cut the prepared glass into 25 mm×10 mm×5 mm samples, and test the ultraviolet excitation emission spectrum after polishing (such as figure 1 Middle—▼—shown in the curve).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com