High density tellurate scintillation glass and preparation method thereof

A technology of scintillation glass and tellurite, which is applied in glass manufacturing equipment, scintillation components, glass molding, etc., can solve the problems of unfriendliness and reduce the mechanical strength of glass, and achieve easy adjustment of chemical components, increase of density, and chemical stability good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] In a specific implementation, the present application provides the above-mentioned high-density tellurite scintillation glass preparation method, which is characterized in that the traditional high-temperature melting method is adopted, that is, the glass raw materials are fully mixed, melted, molded and annealed. Prepared. It specifically includes the following steps:

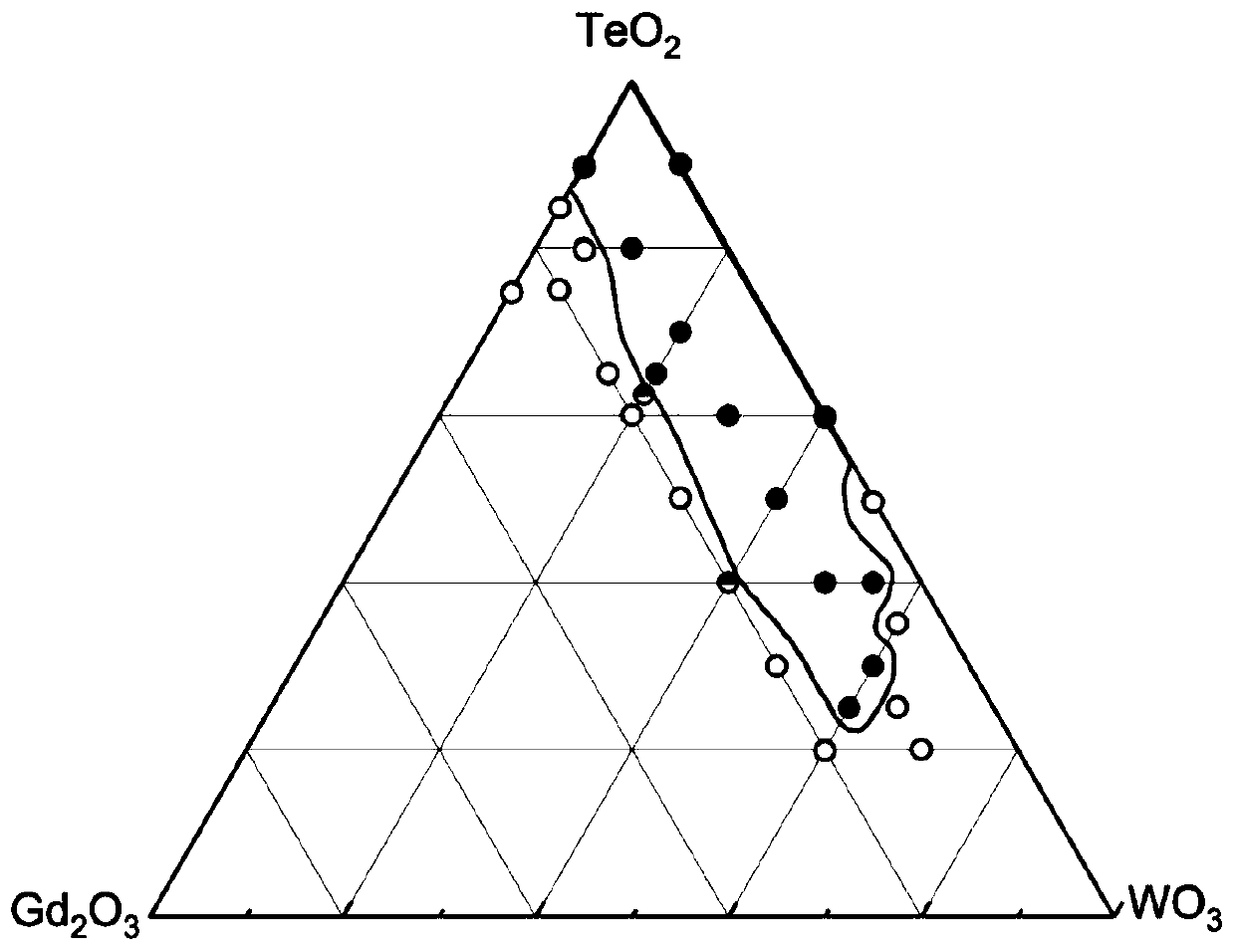

[0068] S1: First, accurately weigh each raw material according to the composition of the scintillation glass, and mix all the raw materials evenly. TeO in the glass component 2 、Gd 2 o 3 、Lu 2 o 3 and WO 3 The four components are directly introduced through the corresponding raw materials, while the activator ions are introduced through the corresponding rare earth oxides, rare earth fluorides, rare earth carbonates or rare earth nitrate compounds; the purity of all raw materials is analytically pure or above;

[0069] S2: Then, pour the uniformly mixed raw materials into an alumina crucible or a...

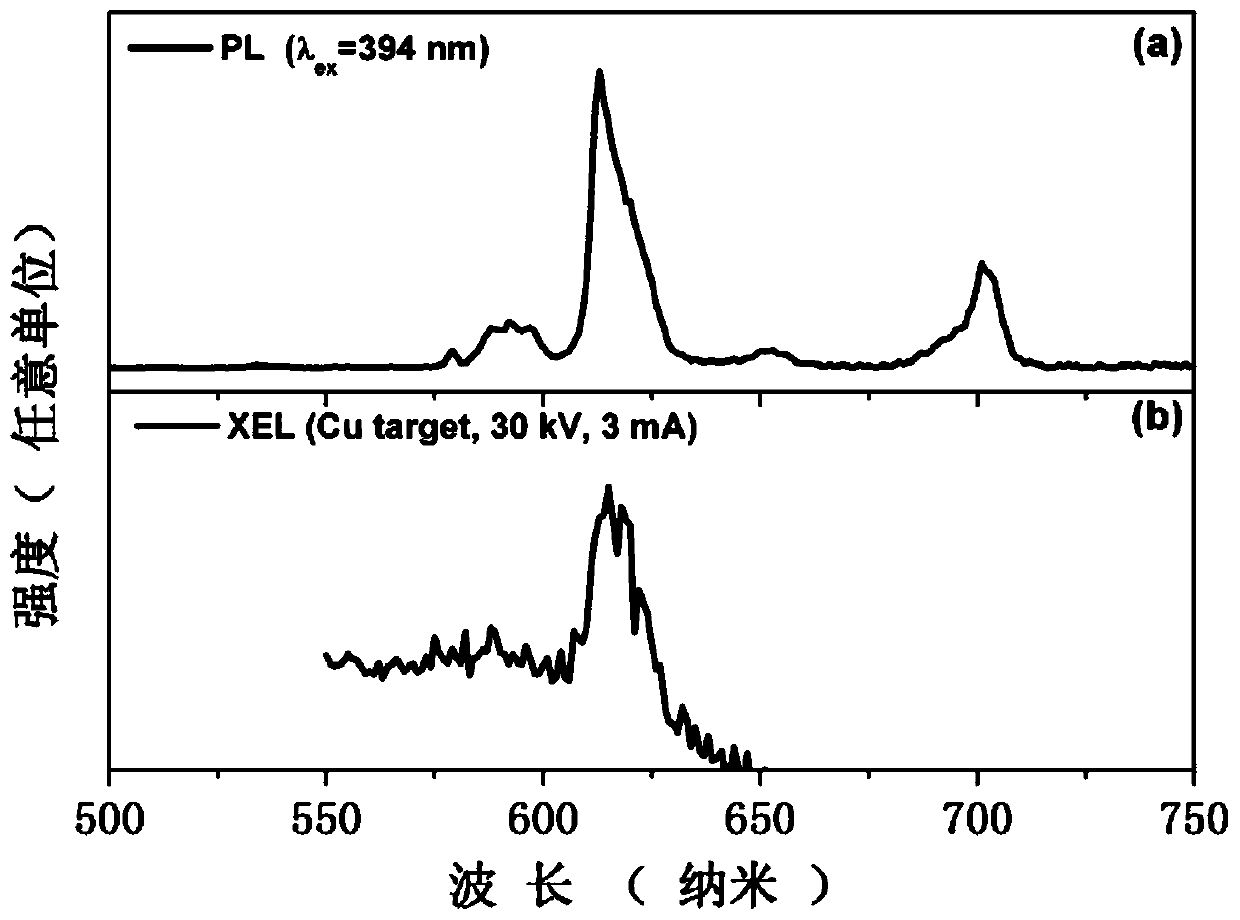

Embodiment 1

[0080] 1. Preparation process

[0081] The concrete formula of embodiment 1 of the present invention: 50TeO 2 -10Gd 2 o 3 -40WO 3 , where the activator is Eu 3+ ions, through Eu 2 o 3 Introduced, its external doping concentration is 0.25mol%. The melting atmosphere is air.

[0082] Eu in Example 1 3+ The preparation steps of activated high-density tellurite scintillation glass are as follows:

[0083] Step 1: According to Eu 3+ Formula for activating high-density tellurite scintillation glass Accurately weigh each component, mix well and pour it into an alumina crucible, and melt it in an air atmosphere at 950°C for 30 minutes by high-temperature melting method;

[0084] Step 2: Pour the above-mentioned homogeneous melt into a preheated 400°C stainless steel mold for casting, and cool naturally to form glass; and

[0085] Step 3: Put the above glass in a muffle furnace at 440° C. for 3 hours and heat it for 3 hours for annealing treatment to obtain the scintillation...

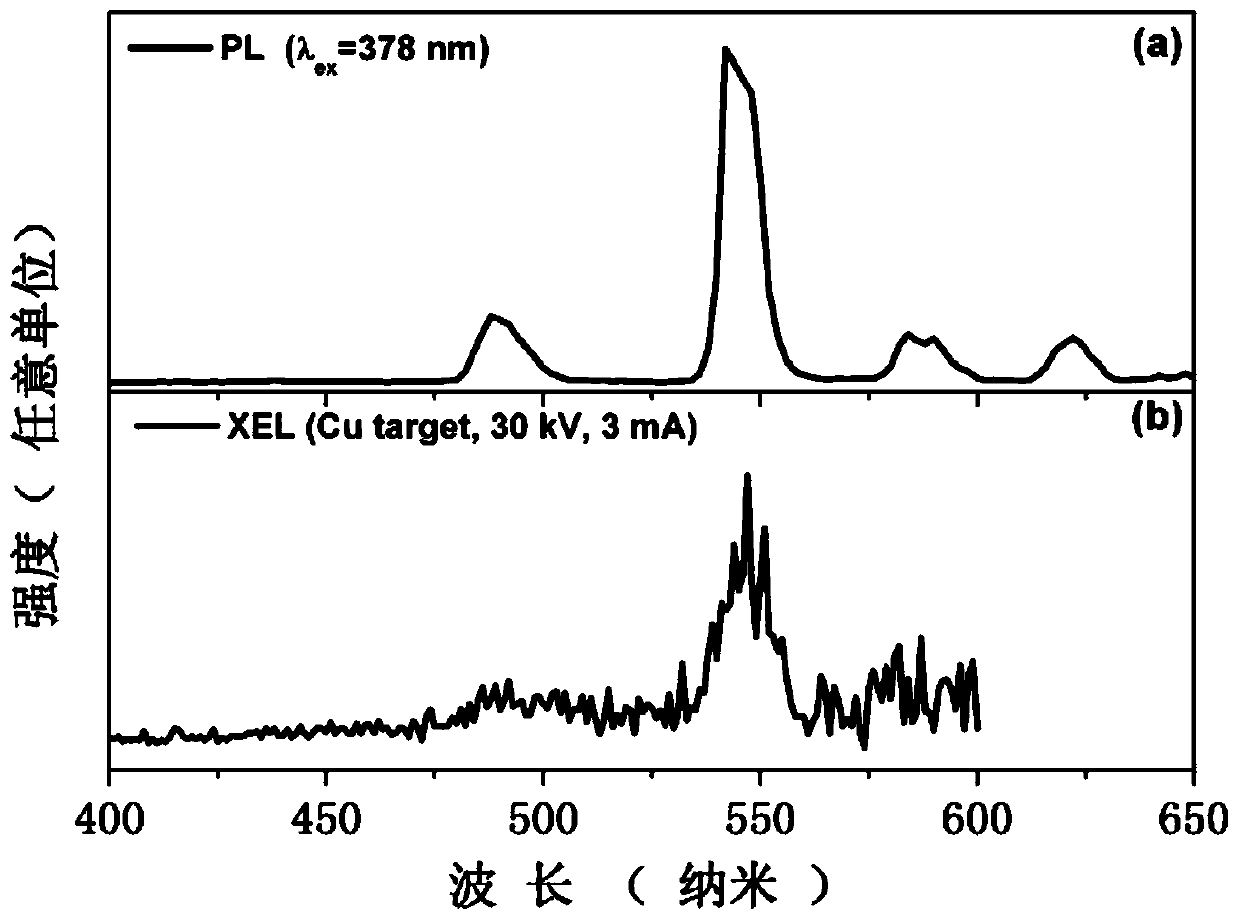

Embodiment 2

[0093] The preparation process is basically the same as in Example 1, except that the glass composition of Example 2 is: 64TeO 2 -16Lu 2 o 3 -20WO 3 , where the activator is Tb 3+ ion, through Tb 4 o 7 Introduced, its external doping concentration is 0.25mol%. The melting temperature is 970°C, and the melting atmosphere is air.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com