Method for preparing lithium iron phosphate serving as cathode material of nano-level lithium ion battery

A lithium ion battery, lithium iron phosphate technology, applied in battery electrodes, nanotechnology, nanotechnology and other directions, can solve the problems of unsatisfactory performance of lithium iron phosphate, poor carbon coating effect, low conductivity, etc., to simplify The effect of production process and equipment investment, easy control of process parameters, and high electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

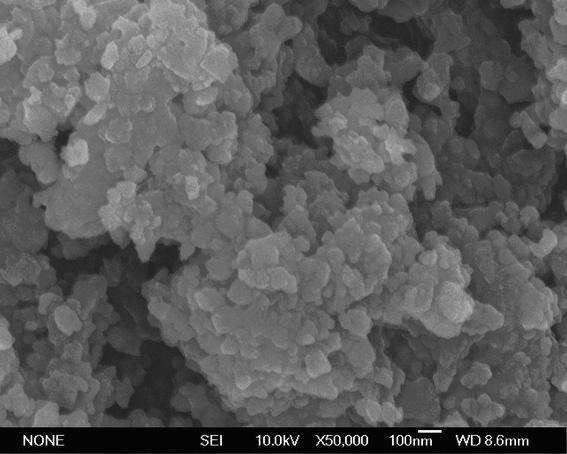

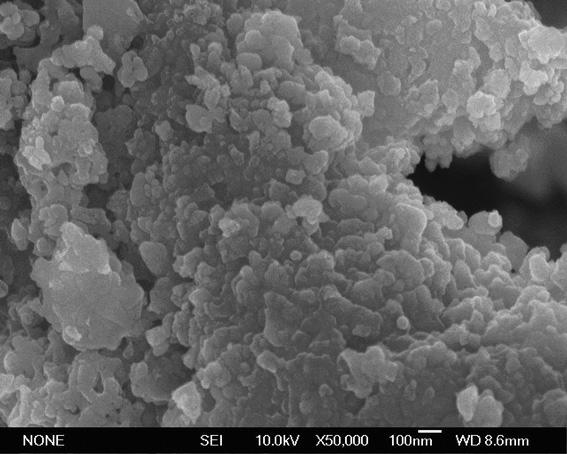

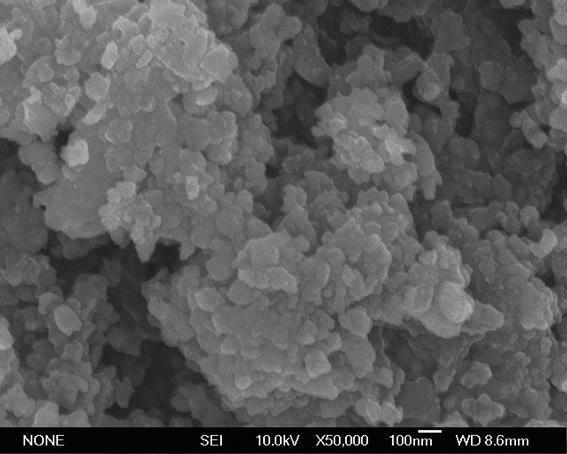

Image

Examples

Embodiment 1

[0030] Embodiment 1, a kind of preparation method of nano-lithium ion battery grade positive electrode material lithium ferrous phosphate, its steps are as follows:

[0031] (1) The composite carbon source raw material is added into an organic solvent to disperse evenly to obtain a composite carbon source solution; the composite carbon source raw material is selected from sucrose, glucose, fructose, sorbose, cellulose acetate, ascorbic acid, cyclodextrin, soluble A composition of at least two of starch, edible oil, citric acid, polyvinyl alcohol, polypropylene alcohol, furyl alcohol, resorcinol, phenolic resin, and epoxy resin; the composition contains at least one with a molecular weight of 100~ 10,000 organic small molecule carbon sources, containing at least one organic polymer carbon source with a molecular weight of 10,000 to 500,000, and the added amount of the organic small molecule carbon source is 1%wt of the final theoretical carbon of lithium iron phosphate, the orga...

Embodiment 2

[0035] Embodiment 2, a kind of preparation method of lithium ferrous phosphate of nanometer lithium ion battery grade cathode material, its steps are as follows:

[0036] (1) The composite carbon source raw material is added into an organic solvent to disperse evenly to obtain a composite carbon source solution; the composite carbon source raw material is selected from sucrose, glucose, fructose, sorbose, cellulose acetate, ascorbic acid, cyclodextrin, soluble A composition of at least two of starch, edible oil, citric acid, polyvinyl alcohol, polypropylene alcohol, furyl alcohol, resorcinol, phenolic resin, and epoxy resin; the composition contains at least one with a molecular weight of 100~ 10,000 organic small molecule carbon sources, containing at least one organic polymer carbon source with a molecular weight of 10,000 to 500,000, and the added amount of the organic small molecule carbon source is 3%wt of the final theoretical carbon of lithium iron phosphate, the organic...

Embodiment 3

[0040] Example 3, in step (1) of the preparation method described in Example 1 or 2, the organic solvent is selected from one or a mixture of ethanol, isopropanol, and acetone.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com