Neodymium iron boron permanent magnet for motor and manufacturing method thereof

A manufacturing method and NdFeB technology, applied in the manufacture of inductors/transformers/magnets, magnetic objects, circuits, etc., can solve the problems of increasing material costs, soaring prices, and increasing manufacturers' costs, to enhance competitiveness, reduce cost, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] 1) Batching process: prepare 100kg / furnace

[0043] 2) Smelting process: use a medium frequency induction melting furnace with single-side cooling ingot mold, put 100kg of ingredients into the furnace in a certain order according to the melting point for melting, pay attention to the yield of steel ingots, and control the vacuum degree at 5×10 -2 Pa.

[0044] The smelting temperature is mainly to melt all the metals. Since the melting point of the added rare earth is not high, the maximum temperature depends on the temperature of the refractory alloy. Generally, it is pure iron and ferroniobium, and the temperature is 1600-1700 degrees Celsius.

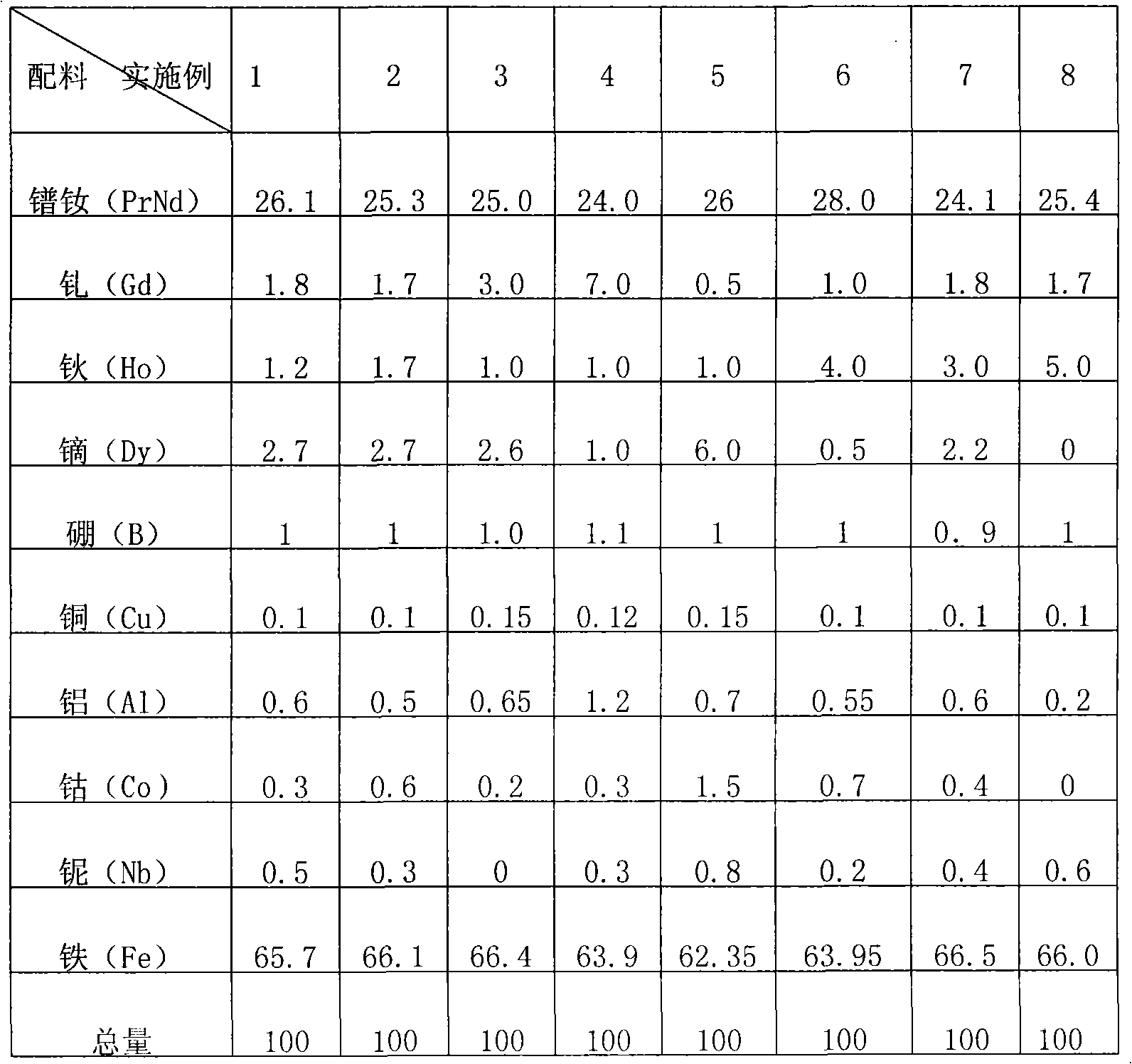

[0045] Table 1 Composition and weight of NdFeB permanent magnets for motors (kg)

[0046]

[0047] 3) Milling process: The homogenized steel ingots are coarsely crushed, medium crushed, and air-jet milled to make NdFeB powder with a particle size of 3.6um-4.2um. During this process, the oxygen content should be controlled bel...

Embodiment 2

[0052] Example 2: 0.4% dysprosium oxide was added before the jet mill in the powder making process, the sintering temperature was 1090°C / 4h+920°C / 3h+560°C / 3.5h, and the others were the same as in Example 1. Specific properties of the produced N35SH material: Br=12.13KGs, Hcj=21.00Koe, (BH)m=35.60MGO, ρ≈7.550g / cm 3 .

Embodiment 3

[0053] Example 3: 0.2% dysprosium oxide was added before the jet mill in the powder making process, the sintering temperature was 1090°C / 4h+940°C / 2.5h+560°C / 4h, and the others were the same as in Example 1. Specific properties of the produced N33SH material: Br=11.81KGs, Hcj=20.20Koe, (BH)m=33.200MGO, ρ≈7.550g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com