System and method for detecting hoisting prevention on basis of laser

A detection system and detection method technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of unsatisfactory safety needs, dependence, and uncertainty of box car separation detection, so as to improve safety and avoid production The effect of the accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

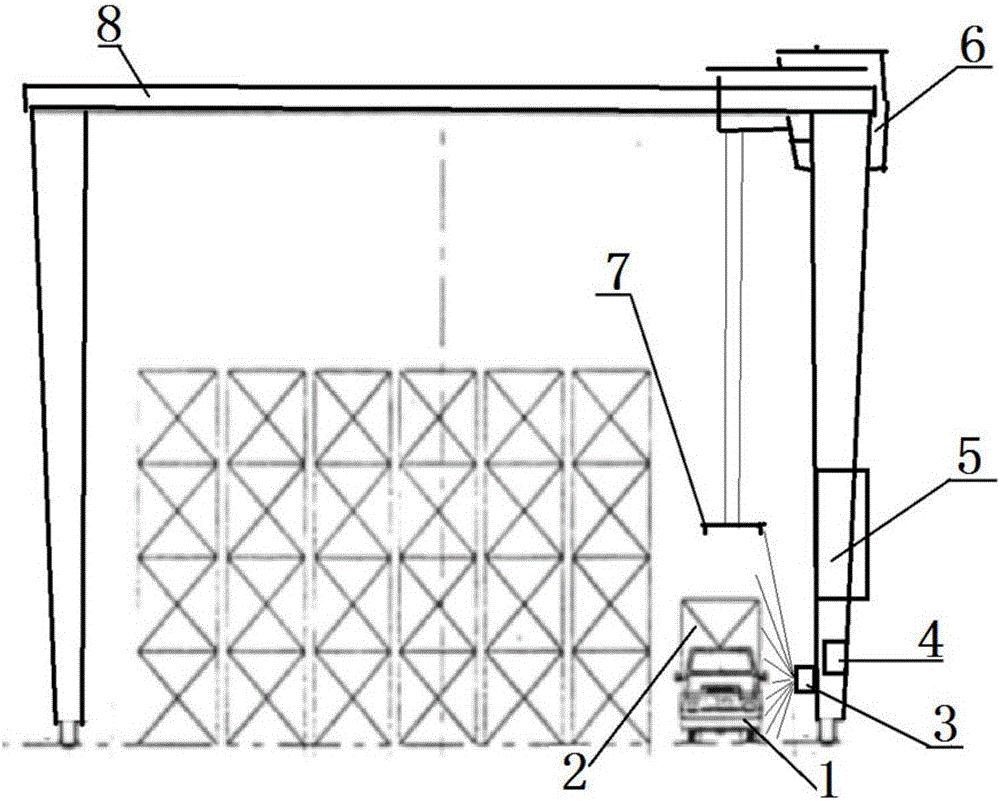

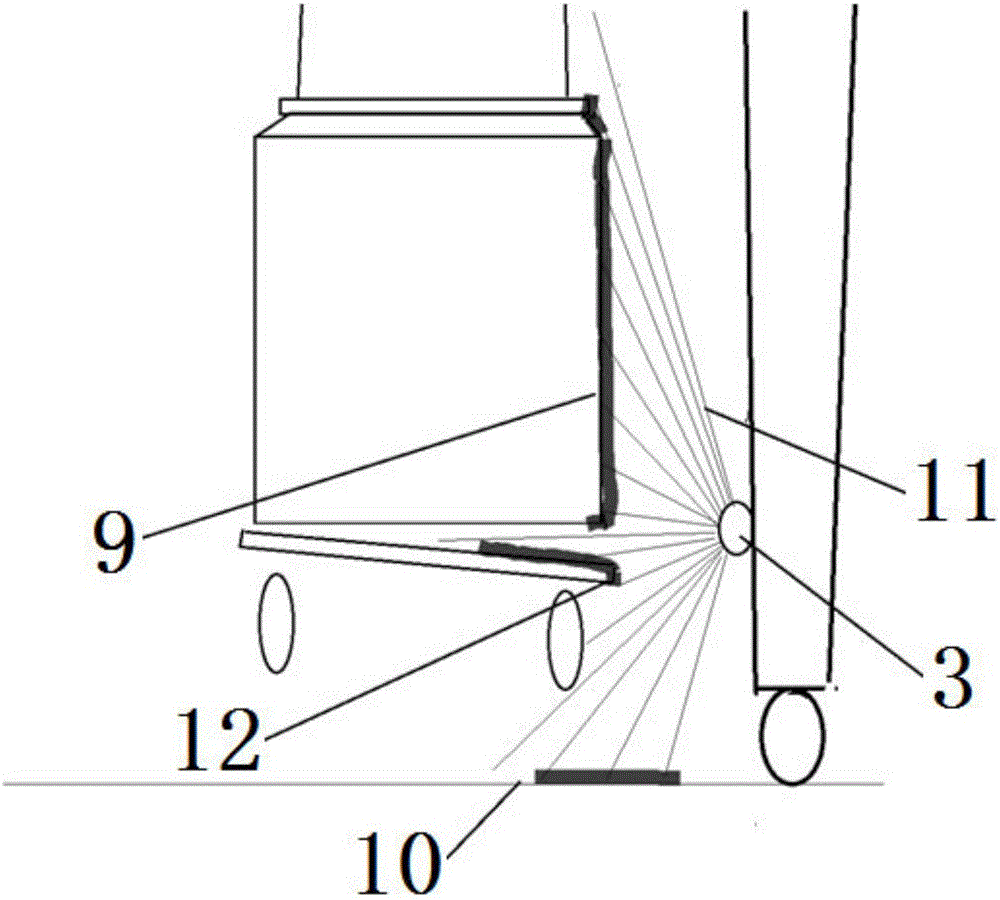

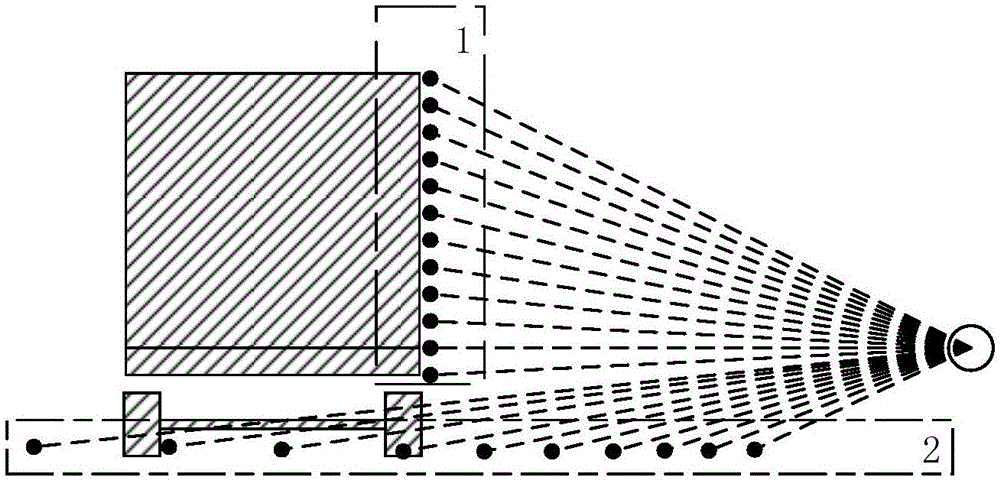

[0016] A laser-based anti-lift detection system such as figure 1 As shown, it includes: work collection truck 1, container 2 on the collection truck, laser scanner 3, logic operation unit 4, PLC control system 5, trolley cab 6, spreader 7, RTG / RMG (container operation gantry crane) 8.

[0017] The laser scanner 3 and logical operation unit 4 of the system equipment are installed below the side of the working lane of the RTG / RMG (container operation gantry crane) 8, and the installation height of the laser scanner 3 is required to be 180CM from the ground (because the height of the truck does not exceed 150CM). , the installation height is equivalent to at least 30CM higher than the collection truck), the logical operation unit 4 is installed in the outdoor electrical machinery, communicates with the laser scanner 3 through an Ethernet cable, and is connected with the PLC control system 5 through a data cable. When the spreader 7 works to lift the container 2 on the work set tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com