Method for preventing converter from dumping steel

A converter and anti-falling technology, applied in the manufacture of converters, etc., can solve problems such as high risk of shaking furnace operation, steel spilling accidents, equipment safety accidents, etc., and achieve the effect of avoiding non-equipment failure production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

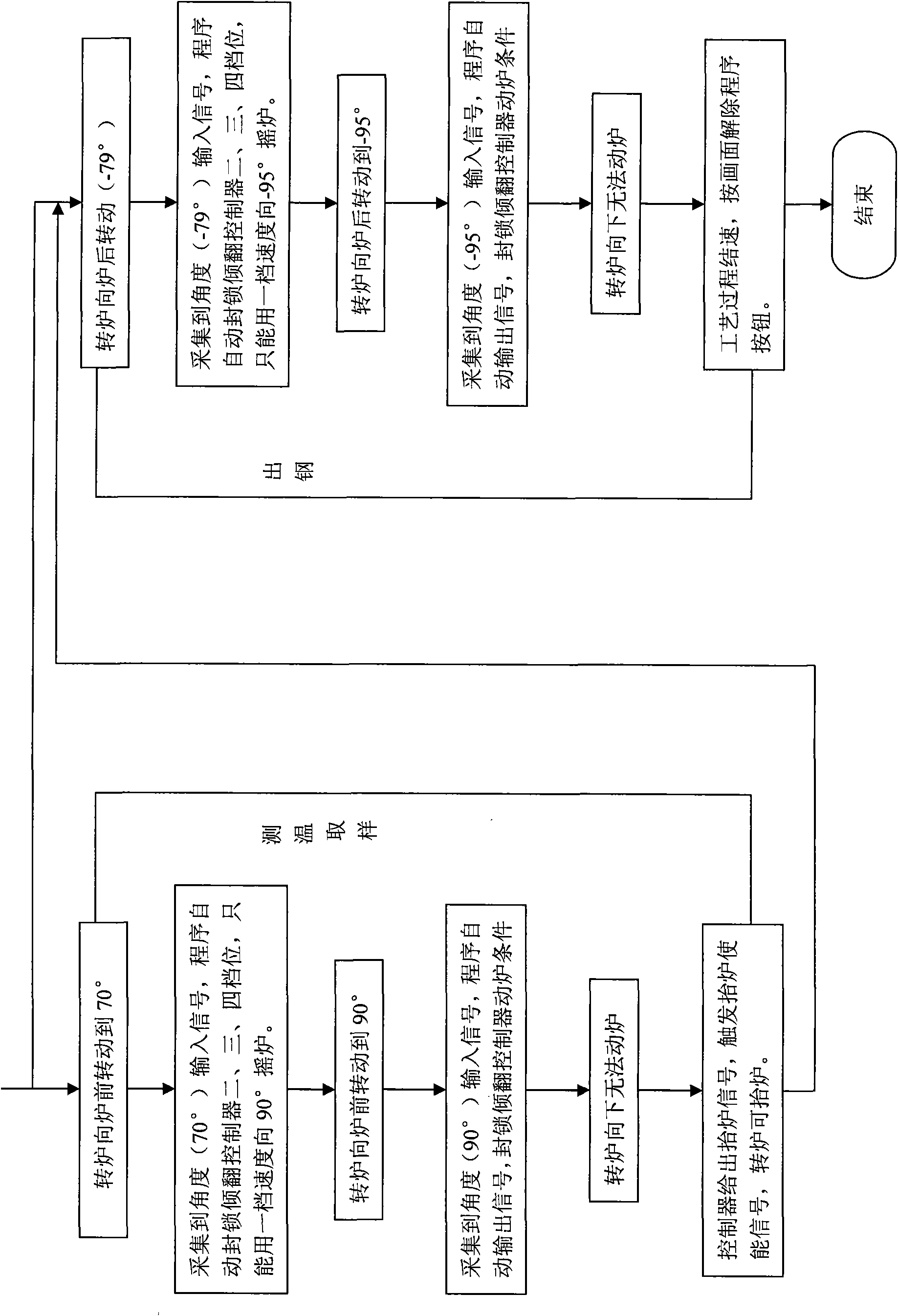

[0011] The system is mainly composed of PLC equipment, converter angle detection device, tilting DC speed control device, etc., and is controlled by PLC program. The system operation is triggered by the converter iron exchange signal, and the chain protection is started during the entire smelting cycle, and the system operation is terminated by the operator clicking the "release button" on the HMI screen as an instruction. The start and stop of the entire system is simple and convenient.

[0012] The smelting cycle of the converter starts with adding iron and ends with the completion of tapping. During this cycle, the converter is rotating in the form of a heavy tank. Therefore, the important part of the operation is within this cycle. Any sloppy operation or violation of regulations will be punished. Cause serious molten steel leakage accident. Before the converter performs the iron mixing operation, the operator needs to press the "iron mixing" button. At this time, the prot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com