Mechanical seal online monitoring system

A monitoring system and mechanical seal technology, applied in engine seals, mechanical equipment, measuring devices, etc., can solve problems such as product blanks, save time and human resources, improve enterprise production efficiency, and avoid production accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further explained below in conjunction with the description of the drawings and specific embodiments:

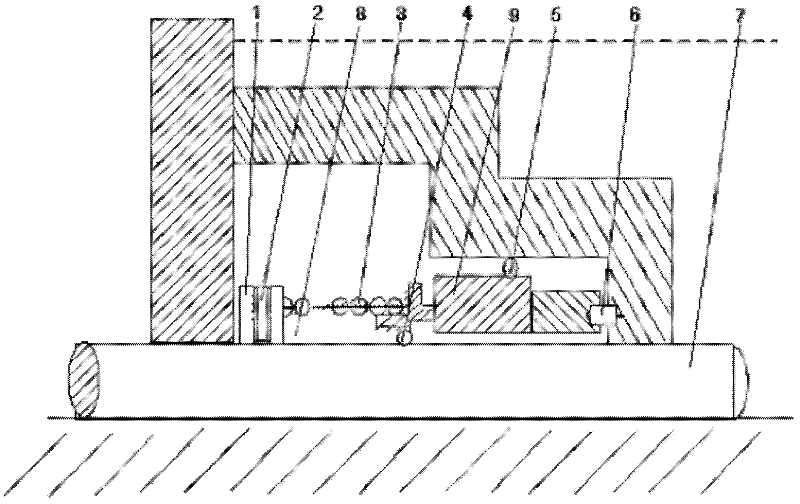

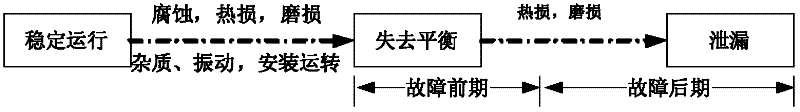

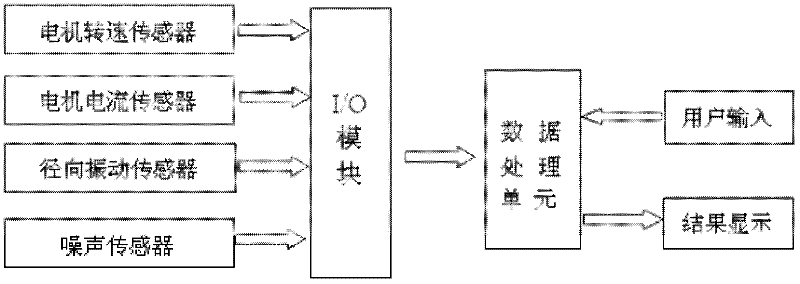

[0028] See Figure 3 to Figure 5 , A mechanical seal online monitoring system, based on a mechanical seal device, including a data processing unit, a detection unit connected to the data processing unit, and a user terminal, the detection unit including an I / O module and a motor speed connected to the I / O module Sensors, current sensors, radial vibration sensors 13 and noise sensors, of which:

[0029] The data processing unit is used to process data from the detection unit and the user terminal;

[0030] The detection unit is used to detect the working state of the mechanical seal device and feed back sensor signals to the data processing unit;

[0031] The user terminal is used to exchange data with the data processing unit and display the monitoring results.

[0032] The motor speed sensor is arranged on the motor shaft 7 and is used to detect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com