Horizontal rotation and flexible movement contact network control system and method thereof

A technology of horizontal rotation and control system, applied in power lines, overhead lines, transportation and packaging, etc., can solve the problems of uneven force on the follower mechanism, poor synchronization, and no tension compensation for the flexible suspension mobile catenary.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in detail below in combination with specific embodiments.

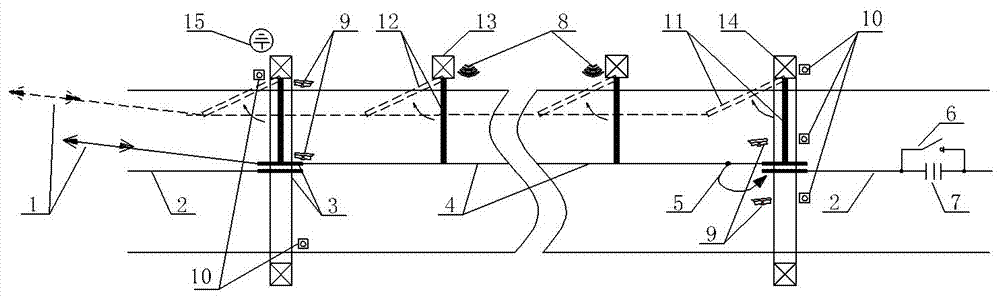

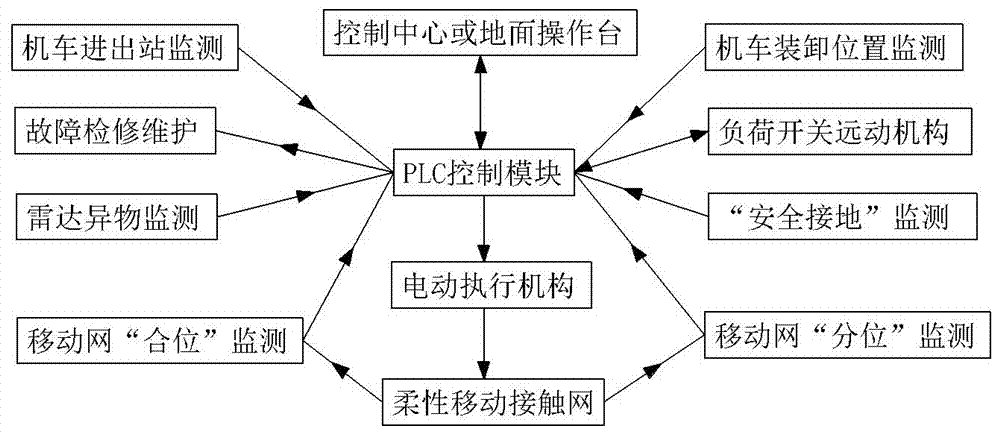

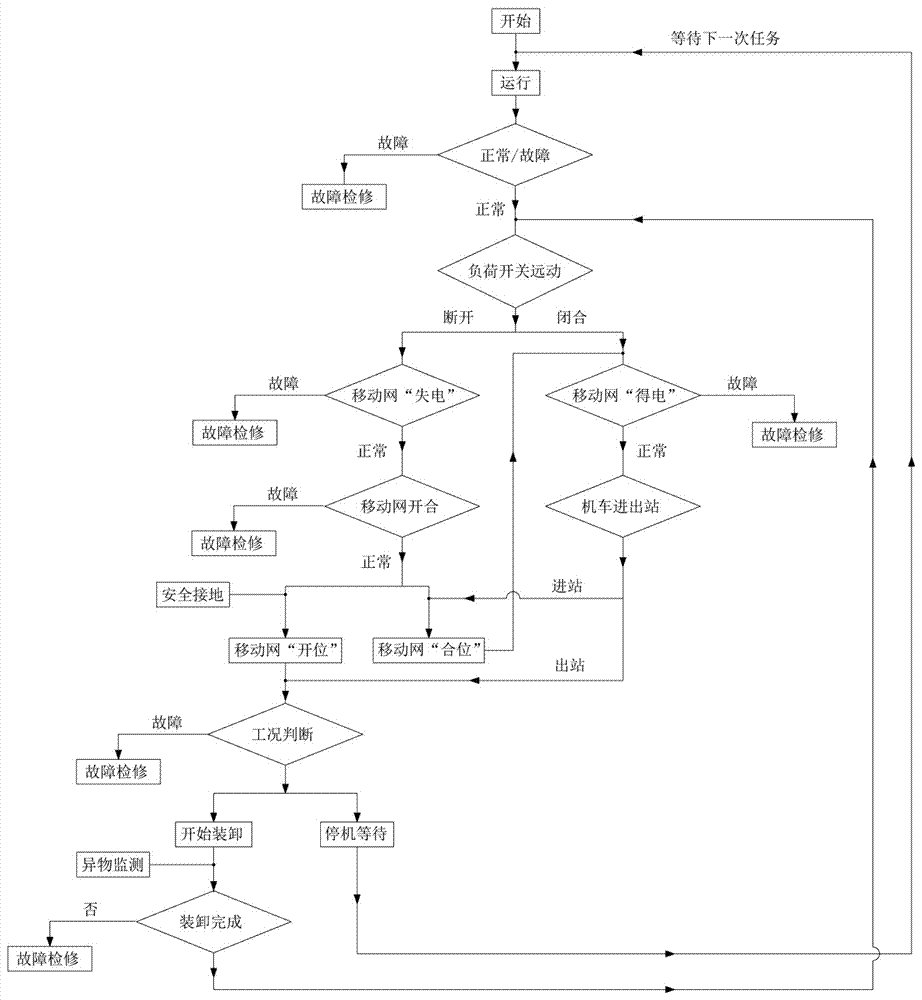

[0038] The horizontally rotating flexible mobile catenary control system involved in the present invention includes a fixed flexible catenary 2 and a mobile flexible catenary 4 in its section.

[0039] The starting end is provided with a power rotating arm 11 installed to the pillar 13 through a rotating shaft, and the power rotating arm 11 rotates horizontally around the pillar 13 under the action of a motor through a wire rope and a pulley block. The middle end is provided with a follow-up rotating wrist arm 12 installed to a pillar 13 through a rotating shaft. The transition end is provided with a follow-up rotating arm 12 installed to the pillar 13 through a rotating shaft, and the terminal is provided with a terminal lower anchor 1; the follow-up rotating arm 12 is connected with the terminal lower anchor 1 through a wire rope and a pulley block. The connecting part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com