Reeling machine side guide plate control method for reducing wearing of wear-resisting plate

A side guide and coiler technology, applied in the field of metallurgical manufacturing, can solve the problems affecting the edge and surface quality of the strip, high quality of the edge and surface of the strip, reducing the replacement efficiency of the side guide, etc. and the effect of high surface quality, reduced repair costs, and reduced replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

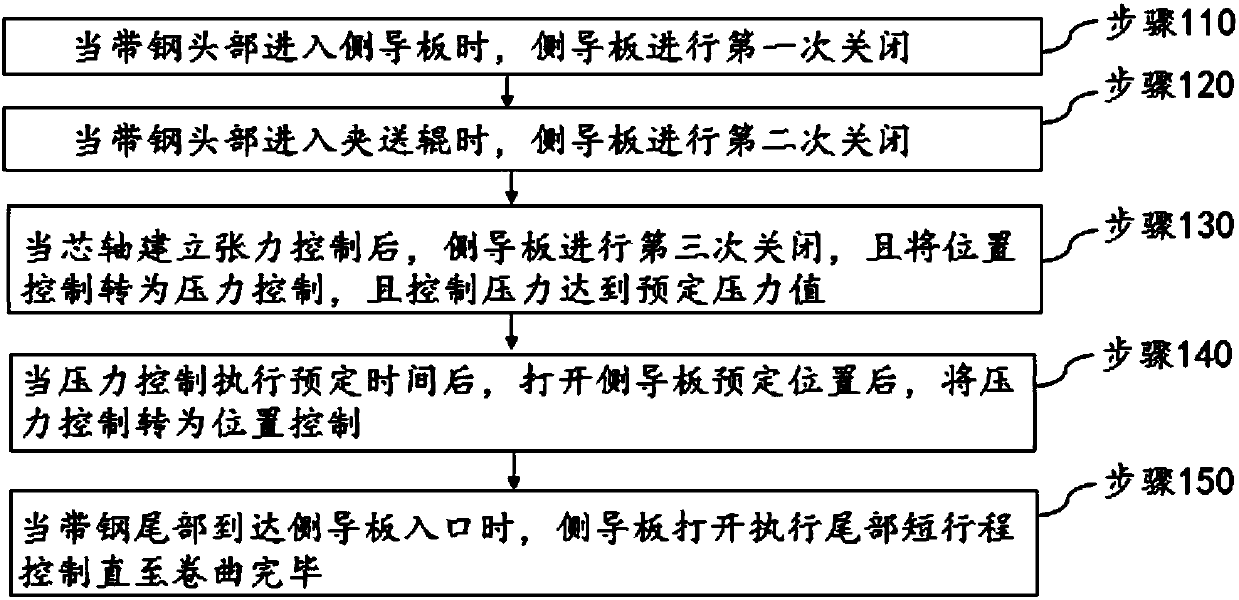

Embodiment 1

[0026] This embodiment provides a method for controlling the side guide plate of the coiler to reduce the wear of the wear plate, such as figure 1 As shown, the method includes:

[0027] Step 110: when the strip head enters the side guide, the side guide is closed for the first time;

[0028] Specifically, the embodiment of the present application detects the position of the steel strip through a hot metal detector, such as detecting whether the head of the strip steel enters the side guide plate through a hot metal detector, such as detecting whether the head of the tiller enters the pinch through a hot metal detector. Rolls, for example, use a hot metal detector to detect whether the tail of the strip is about to enter the side guide plate, etc.

[0029] For step 110, the hot metal detector is used to detect whether the strip head enters the side guide plate. When it is detected that the strip steel head enters the side guide plate, the closing process of the side guide pla...

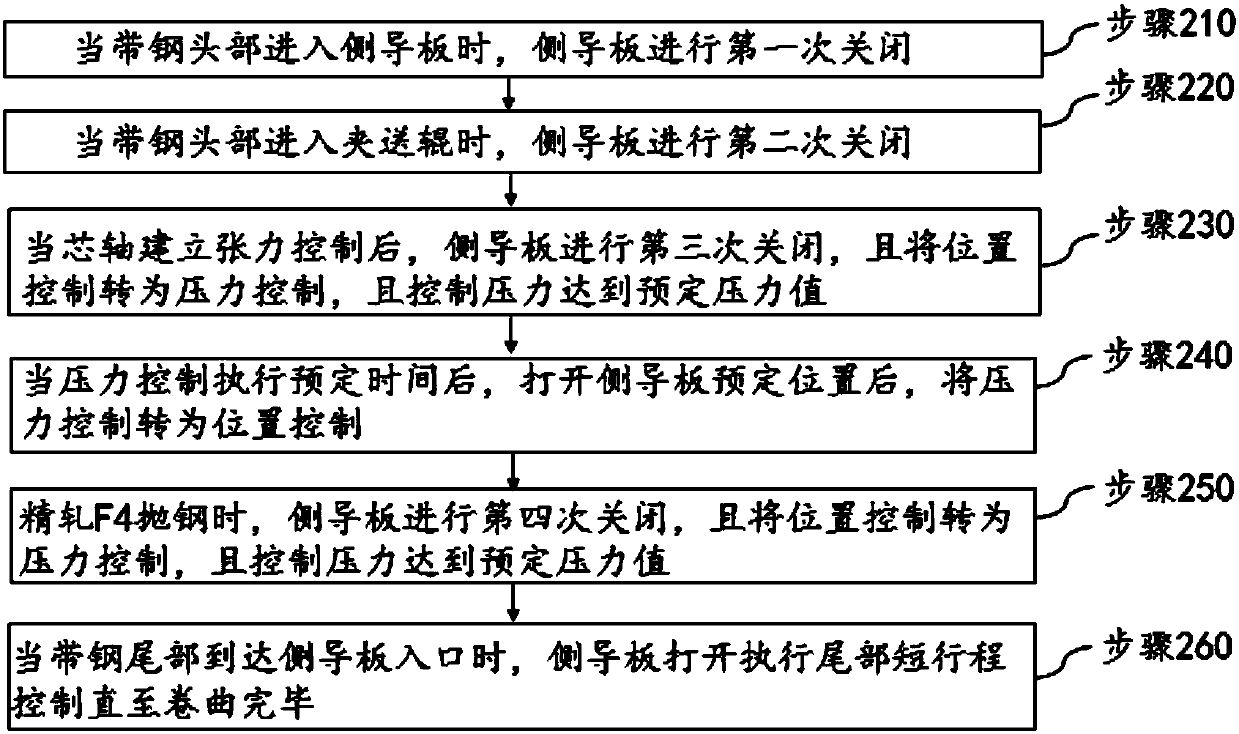

Embodiment 2

[0041] This embodiment provides a method for controlling the side guide plate of the coiler to reduce the wear of the wear plate, such as figure 2 As shown, the method includes:

[0042] Step 210: when the strip head enters the side guide, the side guide is closed for the first time;

[0043] Specifically, the embodiment of the present application detects the position of the steel strip through a hot metal detector, such as detecting whether the head of the strip steel enters the side guide plate through a hot metal detector, such as detecting whether the head of the tiller enters the pinch through a hot metal detector. Rolls, for example, use a hot metal detector to detect whether the tail of the strip is about to enter the side guide plate, etc.

[0044] For step 210, the hot metal detector is used to detect whether the strip head enters the side guide plate. When it is detected that the strip steel head enters the side guide plate, the closing process of the side guide plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com