Manufacturing tool for camshaft bearing cap

A technology for bearing caps and camshafts, which is applied to manufacturing tools, supports, positioning devices, etc., can solve the problems of high pass rate, slow efficiency, low pass rate, etc., to reduce the replacement cycle and efficiency, simplify the processing process, and the technological process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

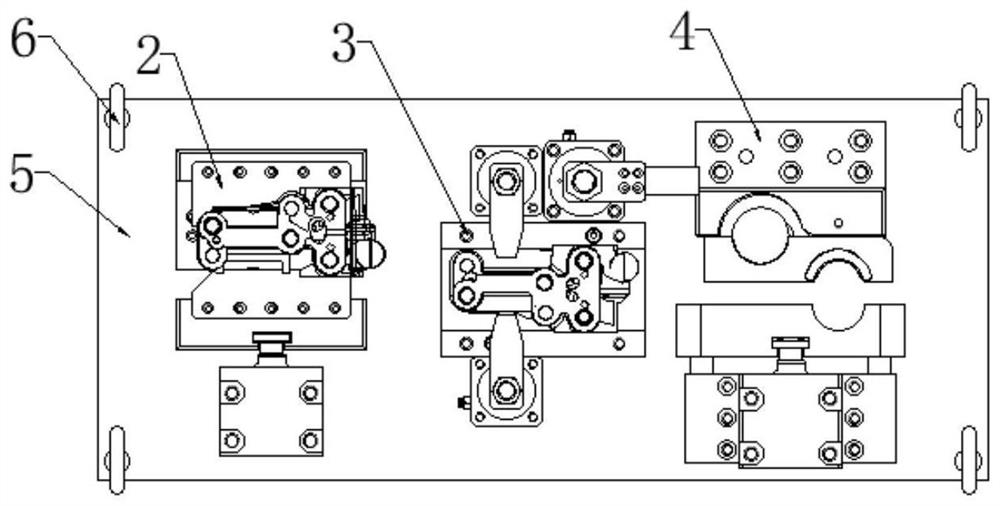

[0026] This example provides Figure 1-5 A preparation tool for a camshaft bearing cover is shown, wherein the preparation tool includes several positioning mechanisms; the positioning mechanism has a pressing assembly for pressing and a positioning assembly for positioning, and the pressing assembly and positioning assembly are arranged on the bottom plate 5 on.

[0027] The positioning mechanism includes a first positioning mechanism 1 , a second positioning mechanism 2 , a third positioning mechanism 3 and a fourth positioning mechanism 4 .

[0028] Each positioning mechanism is further described, wherein the first positioning mechanism 1 includes a first pressing assembly 11 and a first positioning assembly 12; the first pressing assembly 11 is connected with the first positioning assembly 12, and the first pressing assembly 11 and the first positioning component 12 are respectively arranged on the first mounting plate 13 . The second positioning mechanism 2 includes a s...

Embodiment 2

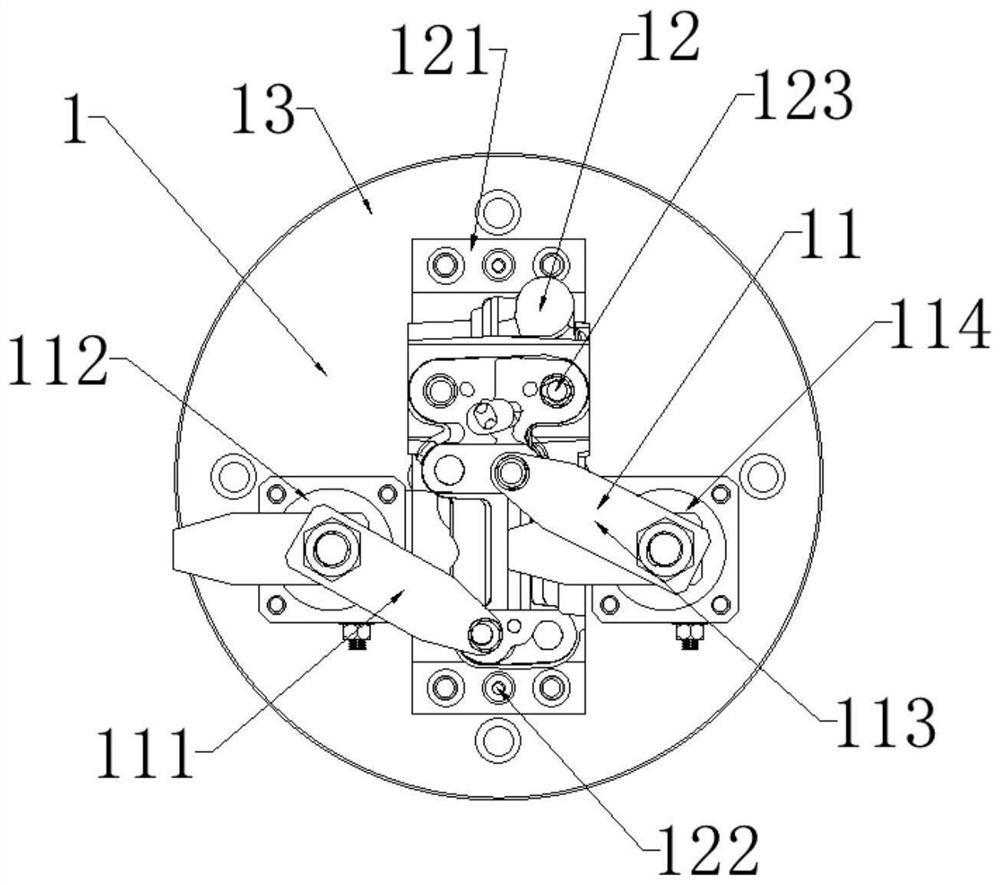

[0032] This example provides Figure 1-2 A preparation tool for a camshaft bearing cap is shown, wherein the preparation tool includes a first positioning mechanism 1, and the first positioning mechanism 1 includes a first pressing assembly 11 and a first positioning assembly 12; the first pressing assembly 11 and The first positioning component 12 is connected, and the first pressing component 11 and the first positioning component 12 are respectively arranged on the first mounting plate 13 .

[0033] The first pressing assembly 11 and the first positioning assembly 12 are described in detail below, as attached figure 1 As shown, the first pressing assembly 11 includes a first left pressing arm 111, a first left oil cylinder 112, a first right pressing arm 113 and a first right oil cylinder 114; a first left pressing arm 111 is arranged on the first left oil cylinder 112, The first right oil cylinder 114 is arranged on the first right oil cylinder 114, and the first left pre...

Embodiment 3

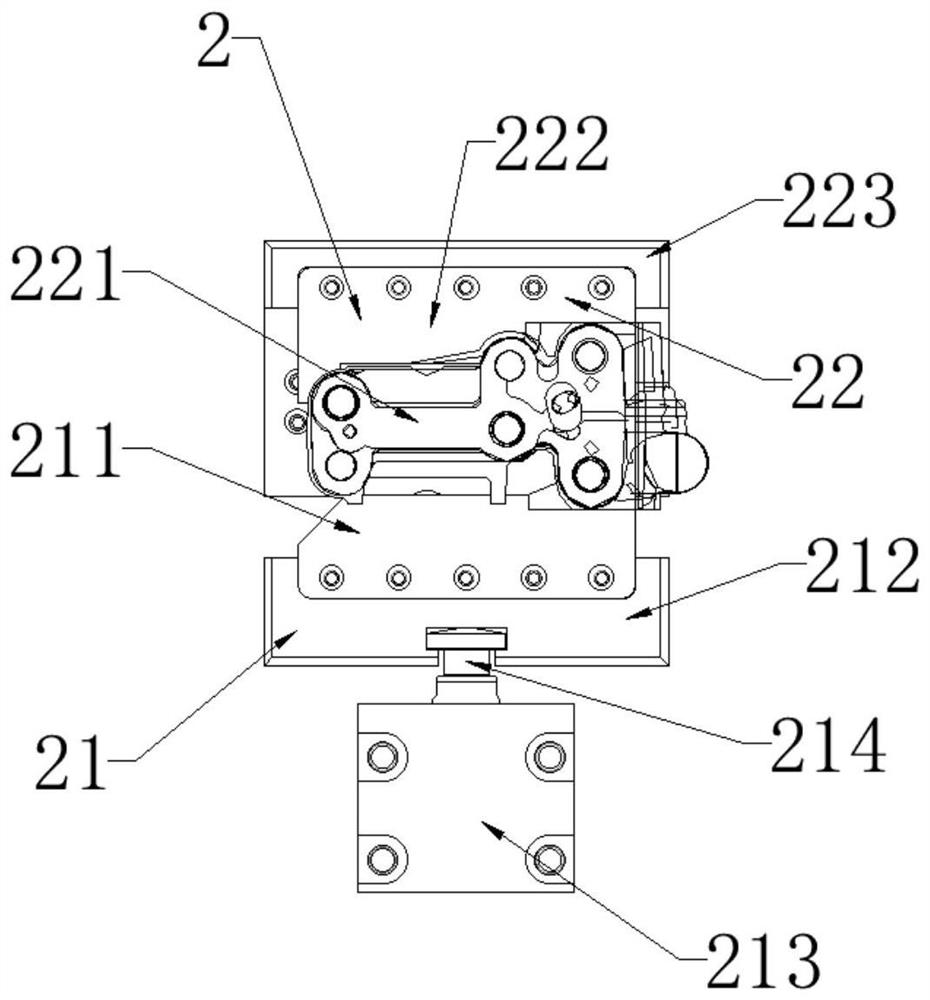

[0036] This example provides Figure 2-3 A preparation tooling for a camshaft bearing cap is shown, wherein the preparation tooling also includes a second positioning mechanism 2, and the second positioning mechanism 2 includes a second pressing assembly 21 and a second positioning assembly 22; the second pressing assembly 21 Connect with the second positioning component 22.

[0037] The second pressing assembly 21 and the second positioning assembly 22 are described in detail below, as attached image 3 As shown, the second pressing assembly 21 includes a second pressing plate 211, a second pressing slider 212, a second oil cylinder 213 and a second oil cylinder ejector rod 214; a second oil cylinder spacer is arranged under the second oil cylinder 213, and the second oil cylinder 213 is connected with the second cylinder jack 214, the second cylinder jack 214 is connected with the second compression slider 212, and the second compression slider 212 is connected with the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com