Steel ladle refining furnace molten steel silicon manganese component control device and method

A technology of a ladle refining furnace and a control method, which is applied in the field of automation control, can solve the problems of not considering economy, inconvenient to popularize and apply, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

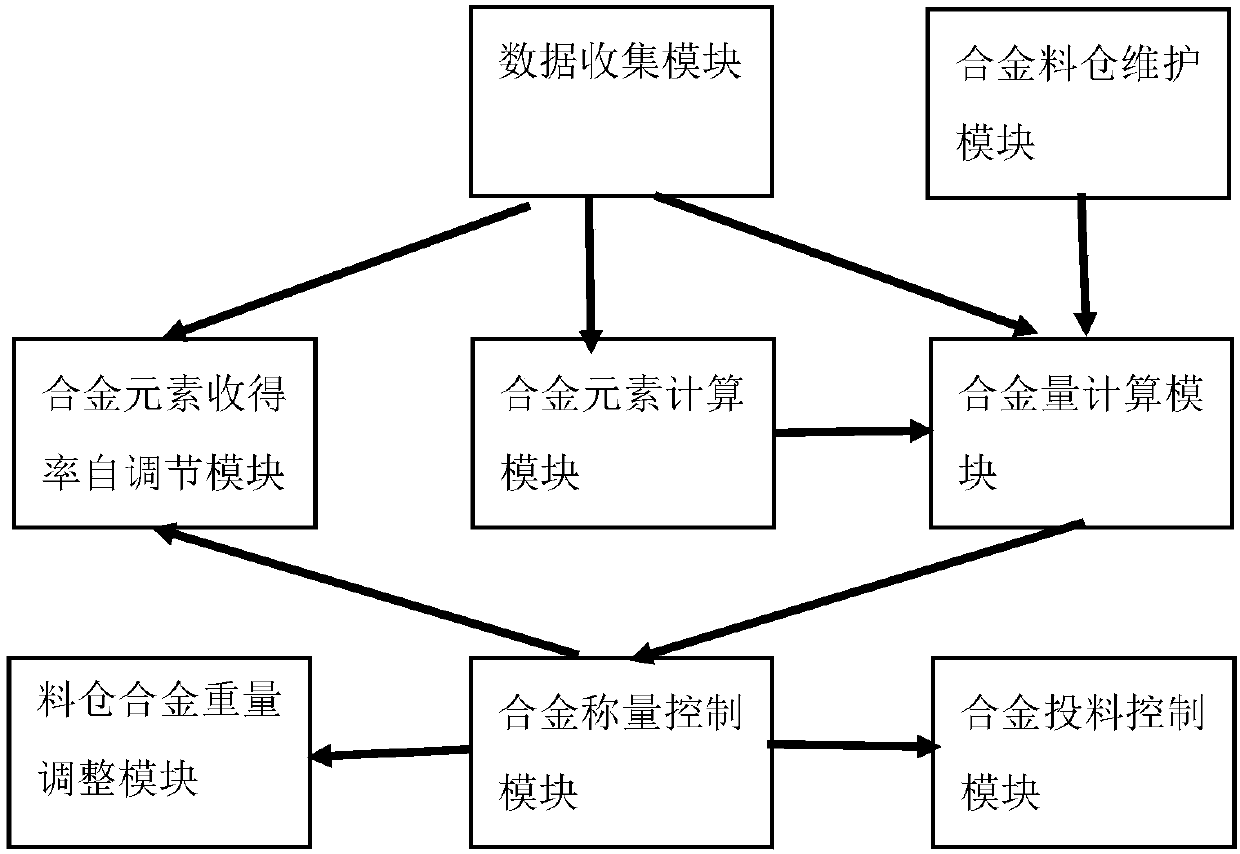

[0116] Example 1: see figure 1 , A kind of ladle refining furnace molten steel silicomanganese composition control device, the control device includes the following control modules:

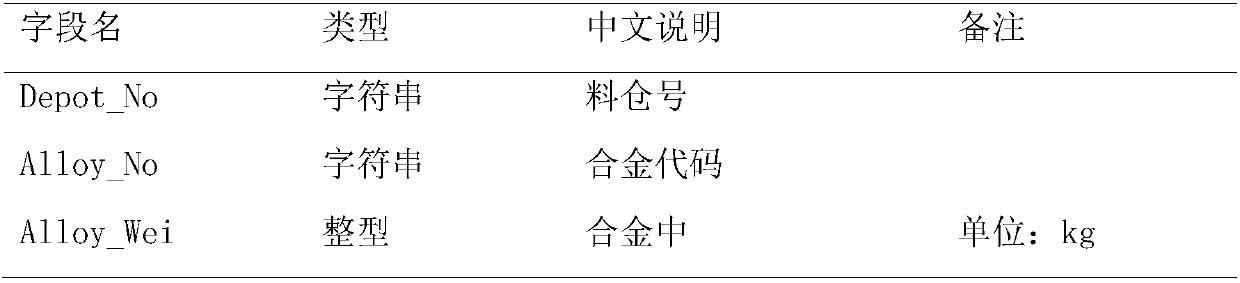

[0117] 1) Alloy silo maintenance module: used to store the alloy storage status of each alloy silo and provide maintenance functions;

[0118] 2) Data collection model: used for the collection and sorting of various calculation parameters;

[0119] 3) Alloy element calculation module: used to calculate the weight of the elements Si, Mn, and C in the input alloy;

[0120] 4) Alloy amount calculation module: used to calculate the weight of alloys such as ferrosilicon, silicomanganese alloy, ferromanganese, high-carbon ferromanganese, medium-carbon ferromanganese and low-carbon ferromanganese;

[0121] 5) Alloy weighing control module: used to control the need to invest in alloy weighing;

[0122] 6) Alloy feeding control module: used for alloy feeding control after weighing;

[0123] 7) Bunker alloy weight adj...

Embodiment 2

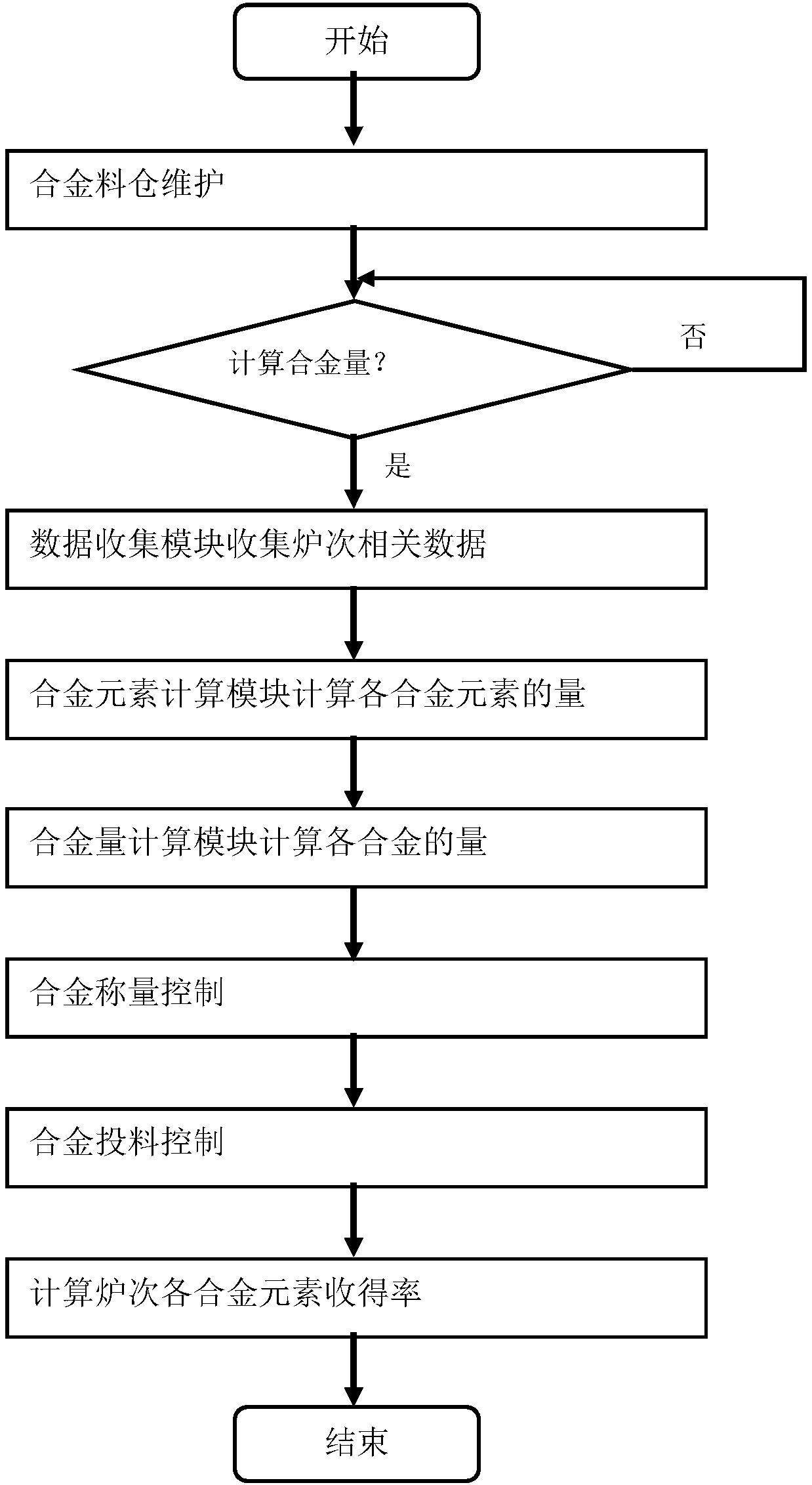

[0125] Example 2: see figure 1 , figure 2 , A method for controlling the silico-manganese composition of molten steel in a ladle refining furnace, ladle refining includes LF refining furnace and RH refining furnace. As the process equipment to realize the intermediate process of converter and continuous casting, the ladle refining furnace must provide qualified molten steel that meets the requirements of quantity and composition, which is a prerequisite for the smooth progress of the subsequent process. As users have higher and higher requirements for the variety and quality of steel, higher requirements have been put forward for the control of the ladle refining process. The manganese alloys used for steelmaking include silico-manganese alloy, ferromanganese, high-carbon ferromanganese, medium-carbon ferromanganese and low-carbon ferromanganese. For manganese-containing steel, not only must the manganese content of the molten steel be qualified, the cost of adding the alloy i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com