Automatic large-diameter pipe deploying and retracting system and transport cart

An automatic retractable, large-caliber technology, applied in the field of pipeline retractable, can solve the problems of high equipment cost, inconvenient transportation and use, and achieve the effect of avoiding production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

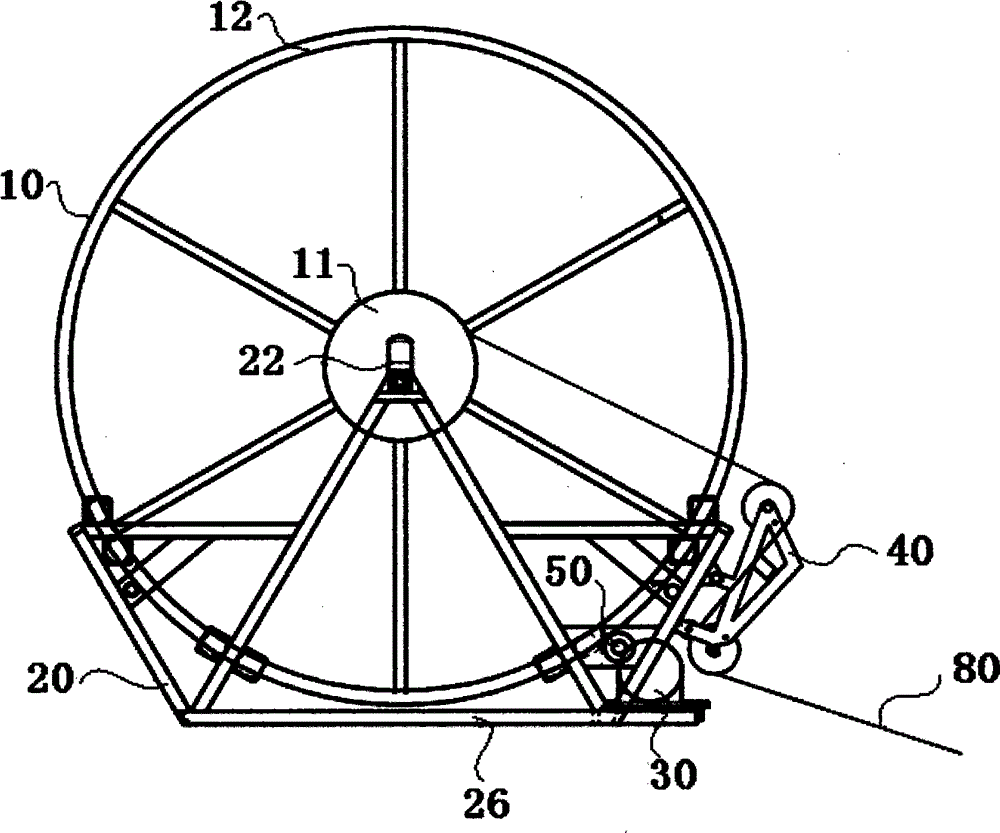

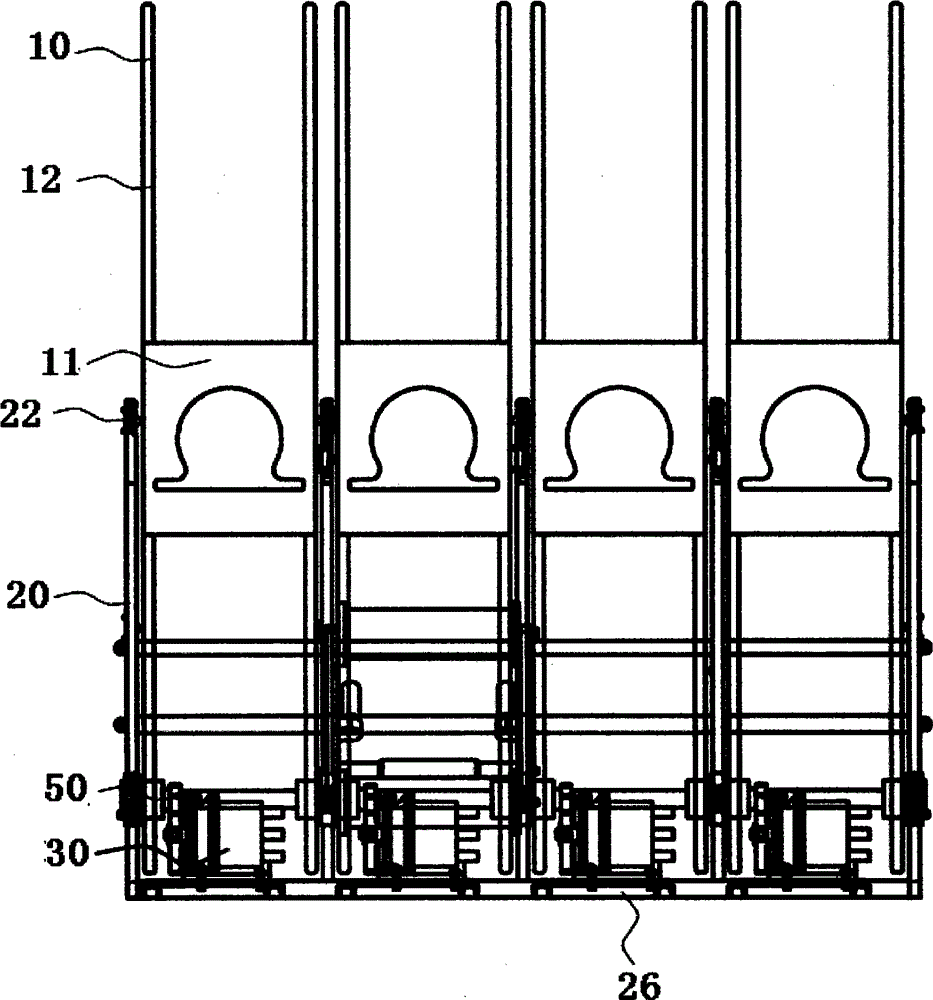

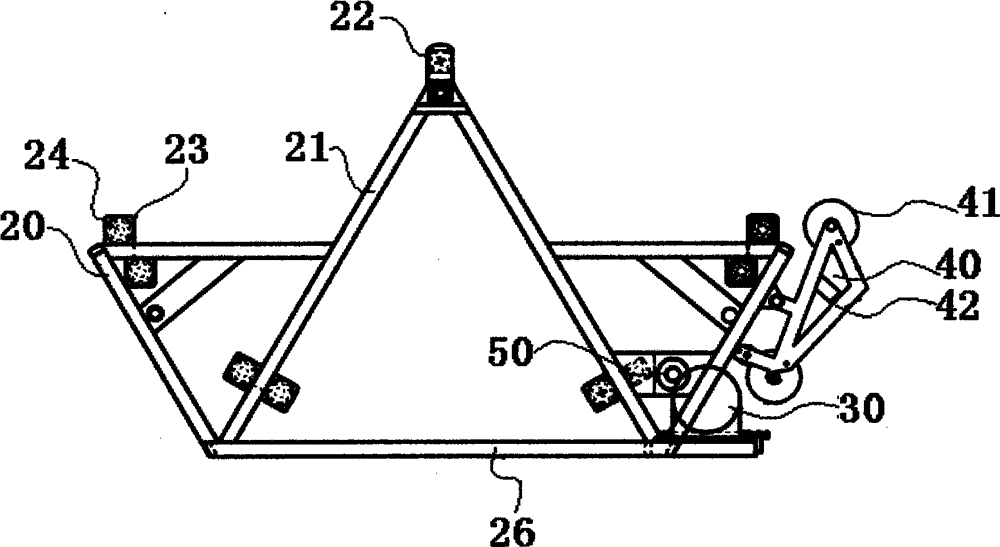

[0032] Such as figure 1 , 2 , 3, and 4, the automatic retracting system for large-diameter pipes of the present invention includes a reel 10, a storage rack 20, a driving source 30 and a power source 60. Wherein, the reel 10 is used for winding the pipe 80 , which includes two rims 12 and a wheel shaft 11 connecting the two rims 12 . The storage rack 20 simultaneously provides storage locations for multiple rolls 10 , including multiple storage spaces 25 partitioned by multiple spacer frames 21 . The spacer frame 21 is provided with the two ends of the wheel shaft 11 by clamping the reel 10 so that the reel 10 is suspended and fixed in the holding seat 22 in the placement space 25. A rotating mechanism 50 for placing the reel 10 in the space 25 . The drive source 30 may be used to drive each of the rotating mechanisms 50 individually. The power source 60 is used to provide power for the driving source 30 and is separated from the storage rack 20 . After the reels 10 are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com