Nylon rope tensile resistance testing device capable of being monitored

A testing device and a tensile force-resisting technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of inconvenience to accurately adjust the distance of the drawstring, inconvenient to fix the nylon rope, and inconvenient to fix the positioning of the device, so as to facilitate accurate stretching. Adjustment operation, convenient and convenient operation, simple and efficient device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

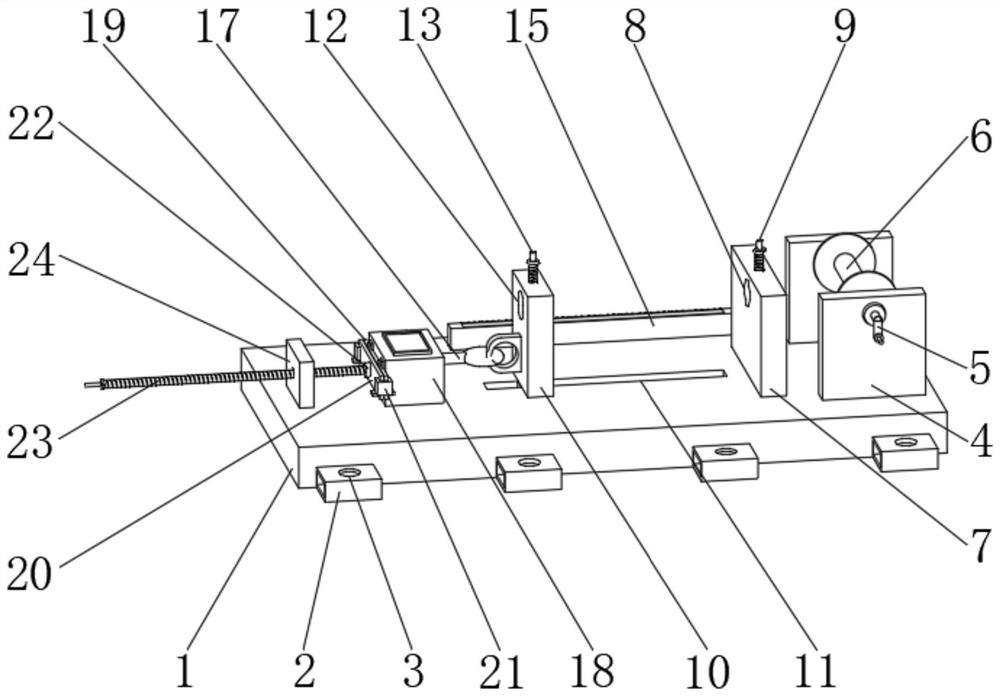

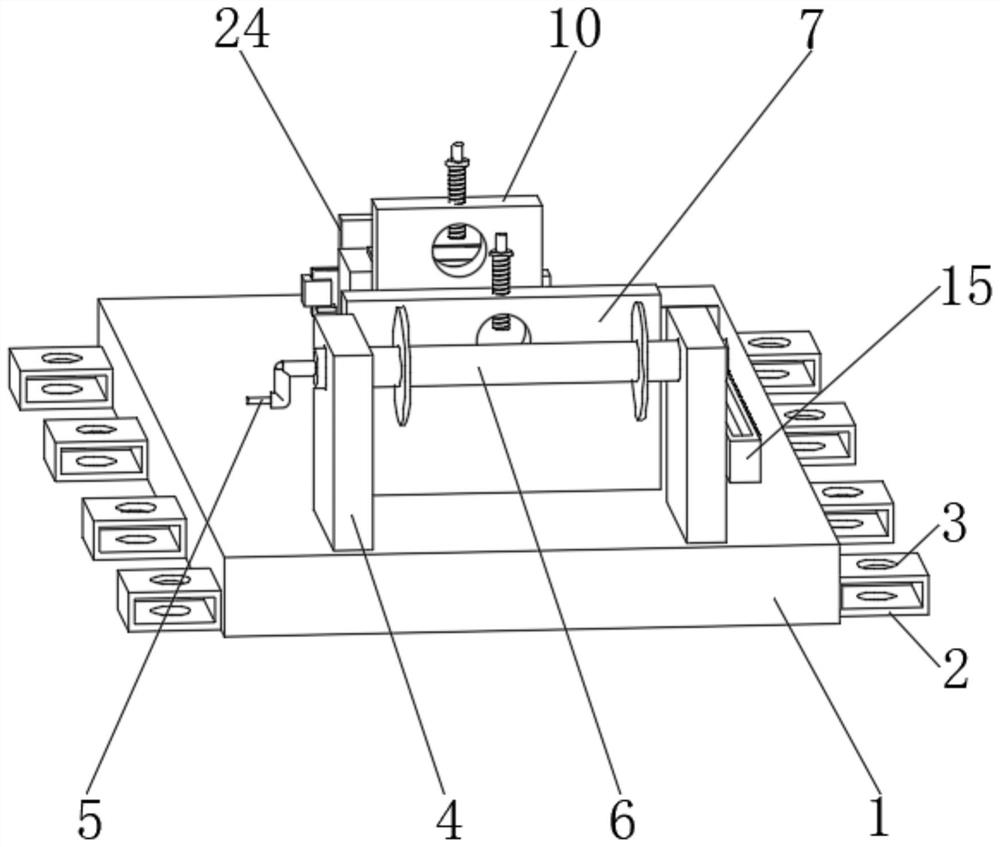

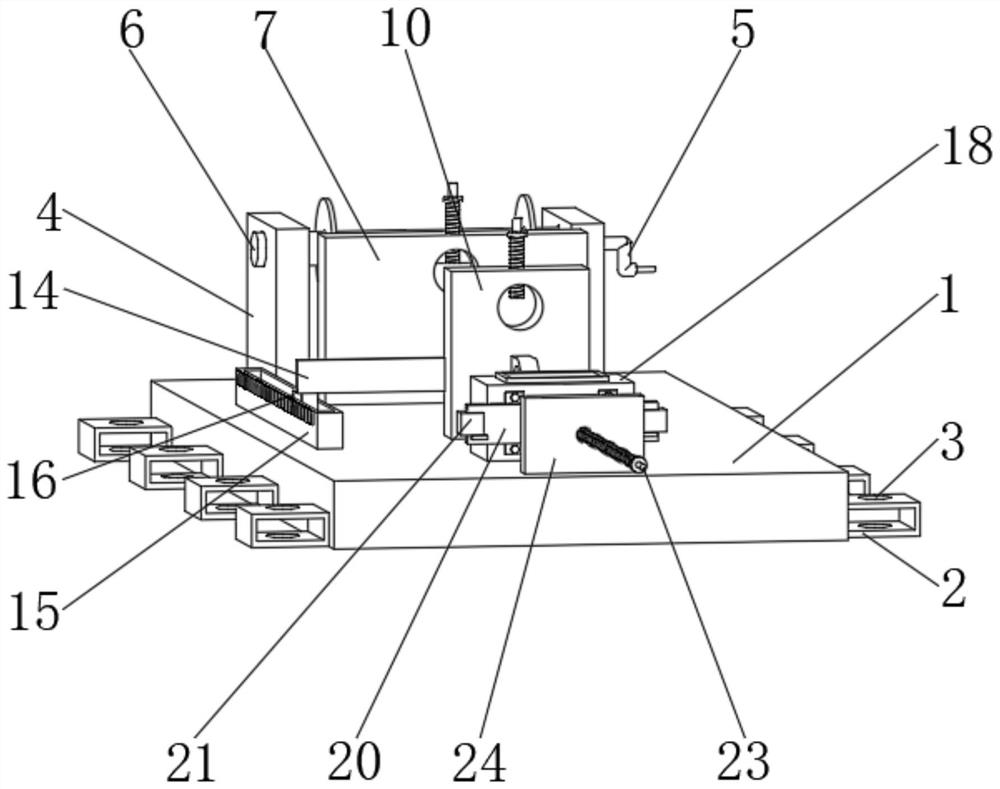

[0027] see figure 2 and Figure 5 As shown, a monitorable nylon rope tensile testing device includes a base plate 1 and a fixed vertical plate 7, the side of the base plate 1 is provided with an connecting plate 2, and the inner side of the connecting plate 2 is provided with a mounting hole 3, the base plate 1 The top of the top is provided with a fixed plate 4, and the outer wall of the fixed plate 4 is provided with a rotating handle 5, and the end of the rotating handle 5 is provided with a winding roller 6.

[0028] There are two installation holes 3 parallel to the inner side of the connecting plate 2, and four pairs of connecting plates 2 are arranged symmetrically with respect to the central axis of the bottom plate 1; the user can realize the installation of the bottom plate 1 through the setting of the connecting plate 2 and the installation hole 3 And fixed, so as to effectively improve the installation and stability of the device, so as to avoid the deviation of ...

Embodiment 2

[0031] see Figure 1-5 As shown, compared with Example 1, as another embodiment of the present invention, the fixed vertical plate 7 is arranged on the side of the fixed plate 4, and the inner side of the fixed vertical plate 7 is provided with a first fixing hole 8, and the fixed vertical plate The top of 7 runs through a first fixing screw 9, the side of the fixed vertical plate 7 is provided with a mobile vertical plate 10, and the bottom of the mobile vertical plate 10 is provided with a sliding rail 11, and the inner side of the mobile vertical plate 10 is provided with a second fixing hole 12, and the top of the moving vertical plate 10 is penetrated with a second fixed screw 13, the side of the moving vertical plate 10 is connected with a connecting plate 14, and the bottom of the connecting plate 14 is provided with a scale seat 15, and the end of the connecting plate 14 is provided with There is an indicator 16, the outer wall of the mobile vertical plate 10 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com