Vertical-surface grinding system for tableware machining

A grinding and façade technology, used in metal processing equipment, grinding/polishing equipment, applications, etc., can solve the problems of prone to production accidents, incomplete overall grinding, low production efficiency, etc., to improve processing accuracy, grinding Complete, well-polished effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail with reference to the accompanying drawings and the best embodiments.

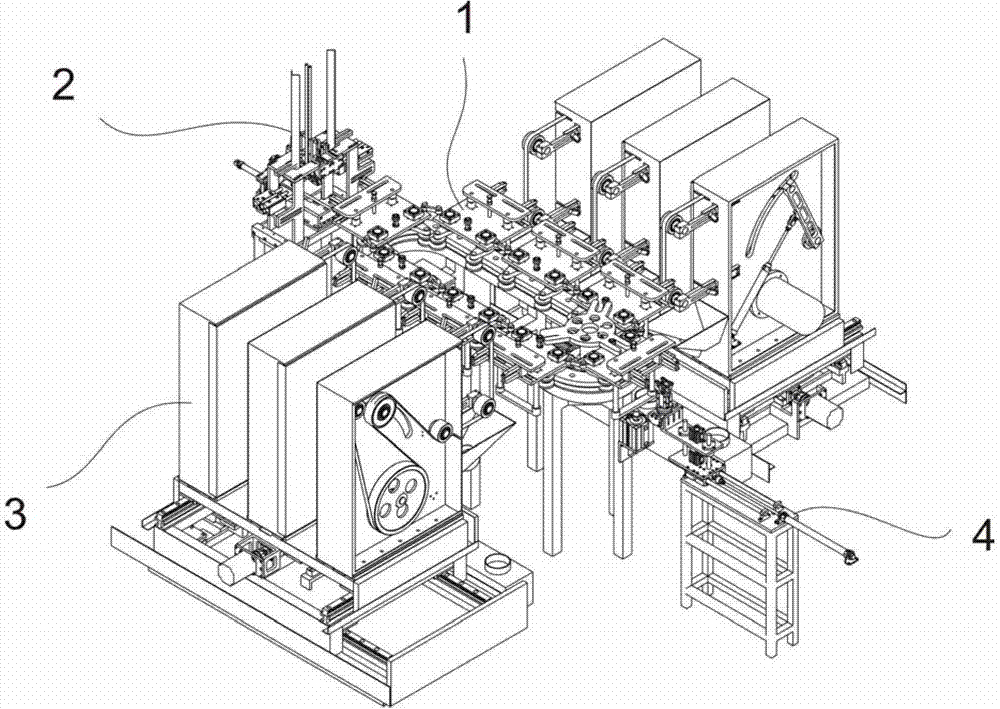

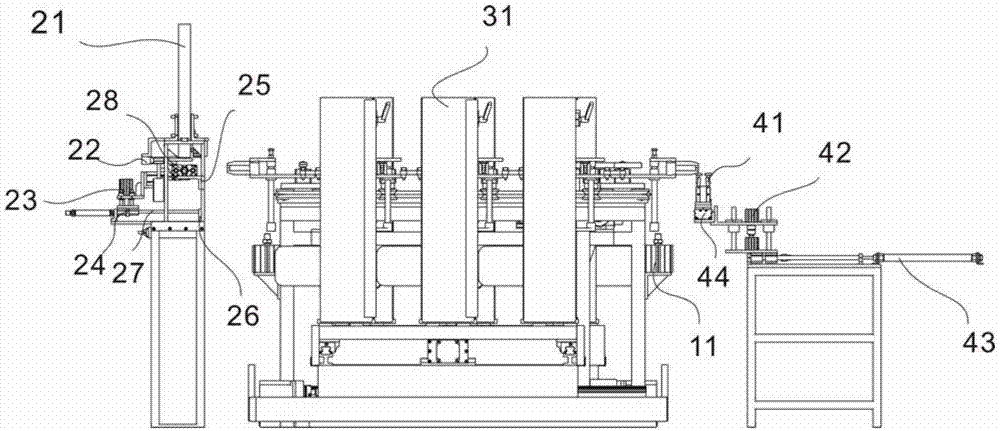

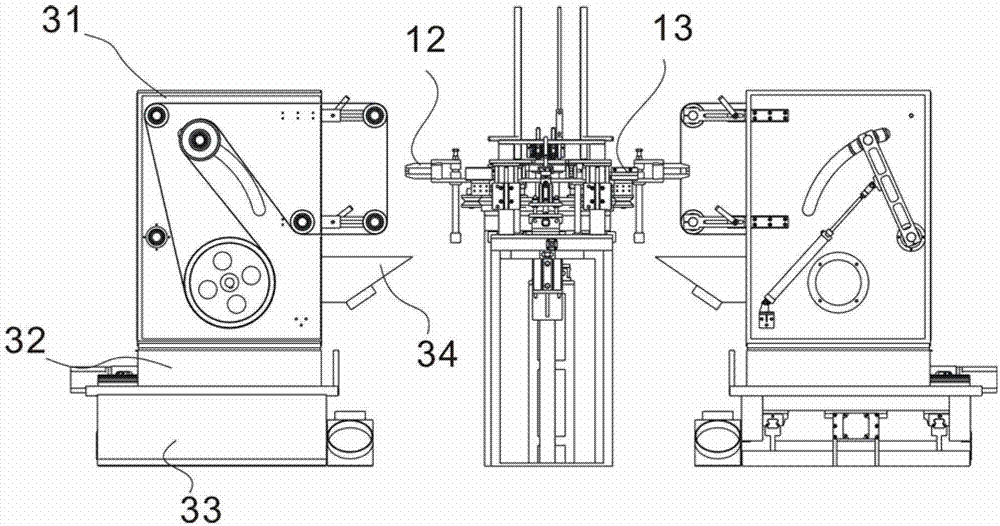

[0023] As shown in the figure, the present invention includes an elliptical rotary material circulation device 1. The two sides of the rotary material circulation device are two parallel forward and reverse grinding stations, and two semicircular opposite stations at both ends They are the loading station and the turning station.

[0024] The rotary material flow equipment includes a flow track 15, a flow frame 13 with a material clamping clip 12 provided on the flow track, and a flow rotation force mechanism. The flow frames are connected to each other by a connecting rod 16.

[0025] A clamping clamp opening and closing cylinder 11 is provided under the corresponding positions of the circulation rack at the loading station and the tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com