Acesulfame cyclization continuous production method

A production method, the technology of acesulfame K, applied in the direction of organic chemistry, etc., can solve the problems of low temperature stability of the reactor, large production ratio error, unstable cryogenic load, etc., to optimize the reaction efficiency and improve the service life , the effect of increasing the economic benefits of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

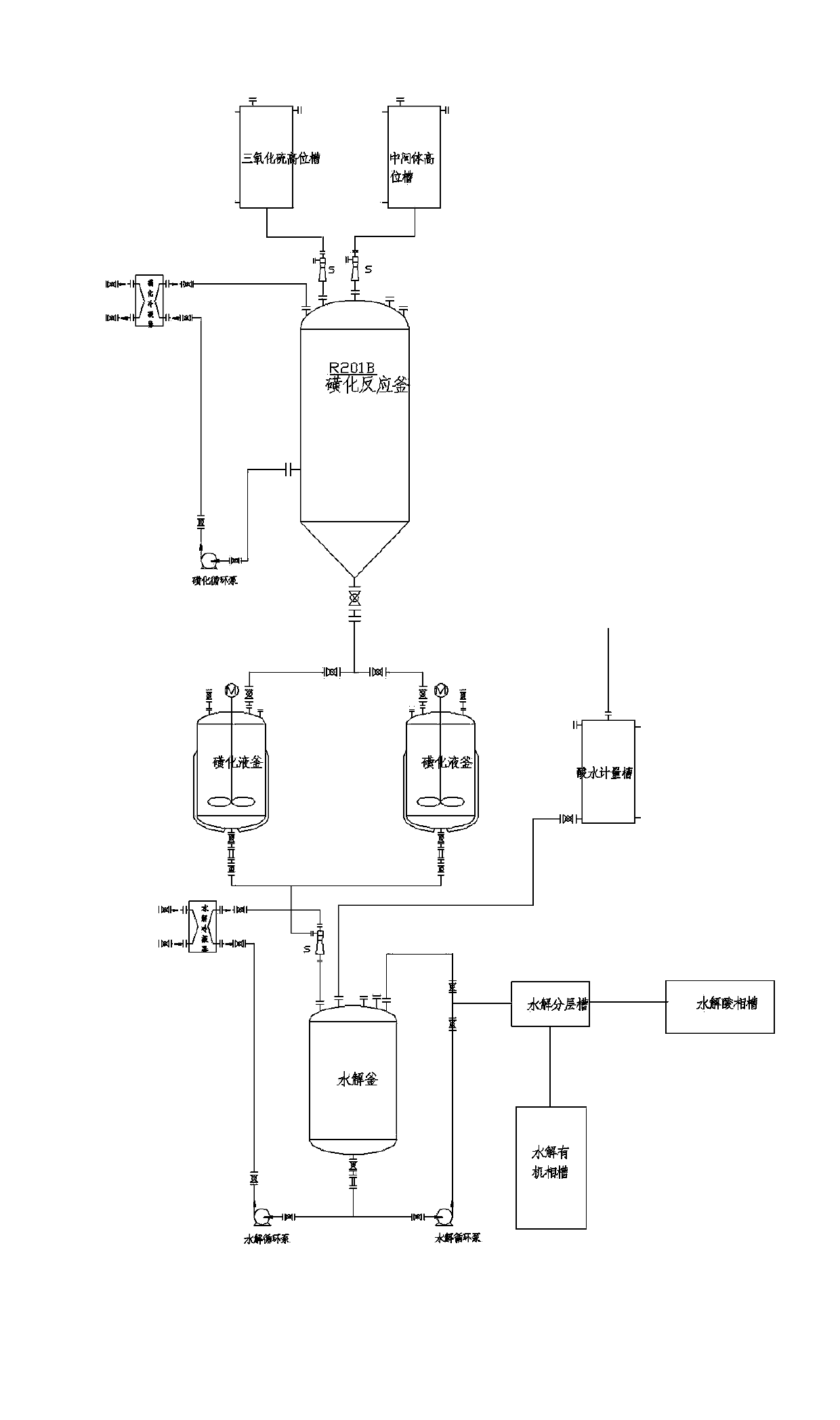

[0015] Example 1, such as figure 1 Shown:

[0016] 1. Preparation of sulfur trioxide solution

[0017] 1.) Add dichloromethane (semi-finished product, moisture ≤0.05%) to the preparation kettle;

[0018] 2.) Start the circulating pump, circulate for 5 minutes, open the sulfur trioxide storage tank valve, and add sulfur trioxide to the preparation kettle;

[0019] 3.) After the feeding is completed, continue to circulate for 20 minutes, and pump the mixture of dichloromethane and sulfur trioxide into the high level metering tank of sulfur trioxide.

[0020] The intermediate tank contains intermediates (that is, the carboxylation product of the synthesis reaction: acetoacetamide-N-sulfonic acid triethylamine).

[0021] 2. Sulfonation reaction

[0022] 1.) Start the circulating pump, cool the material in the sulfonation reactor to below -30°C, and keep the liquid level of the material in the sulfonation reactor at 45-50 liquid level (if the material is not enough to circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com