Method for preparing liquid product containing rich phenols and alcohols through microwave catalytic thermal cracking of forestry and agricultural residues

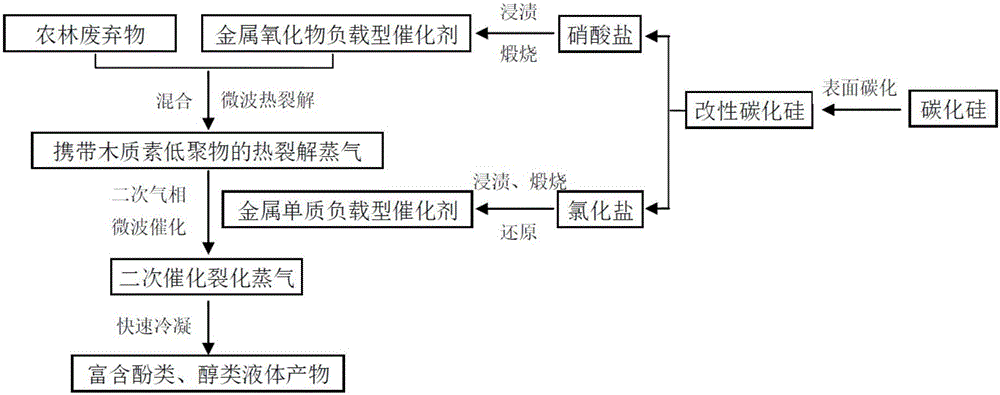

A technology of microwave catalysis of agricultural and forestry wastes, which is applied in the field of alcohol liquid products and microwave catalytic pyrolysis of agricultural and forestry wastes to prepare rich phenols, which can solve the problems of low yield of pyrolysis liquid, non-enrichment of effective components, and heat dissipation Serious problems, to achieve the effect of improving thermal cracking efficiency, promoting rapid carbonization, and not easy to coke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

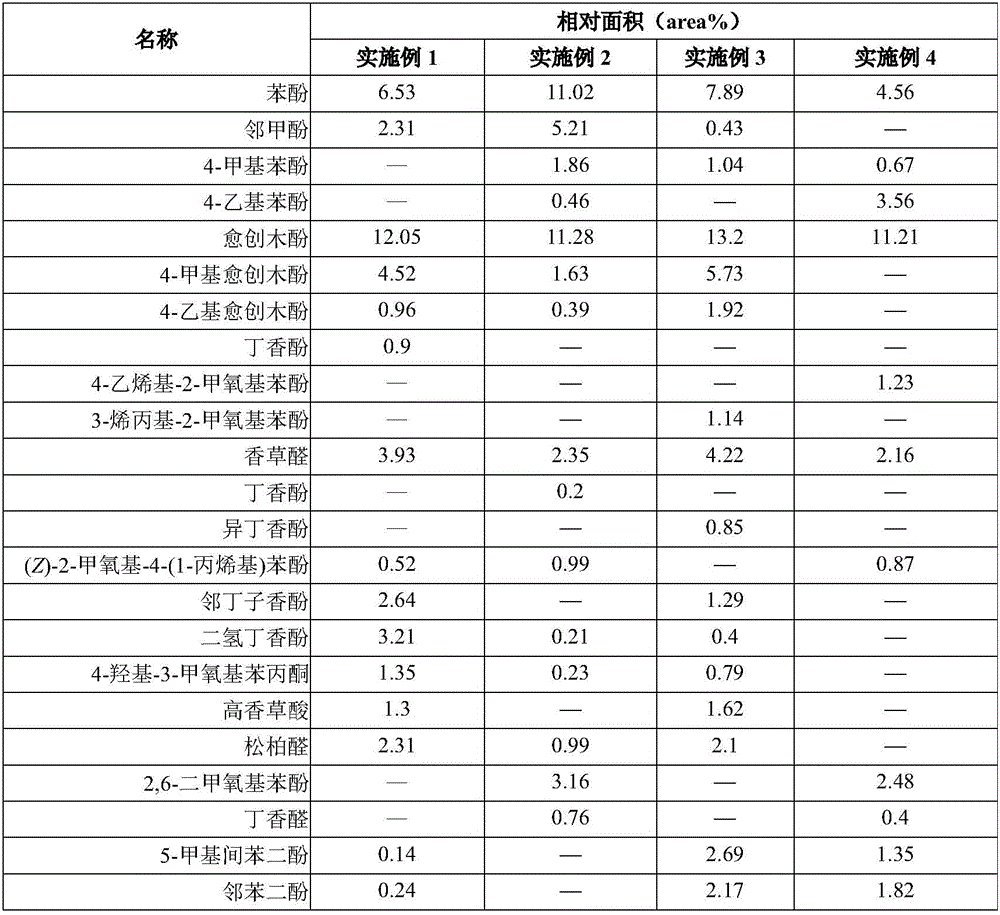

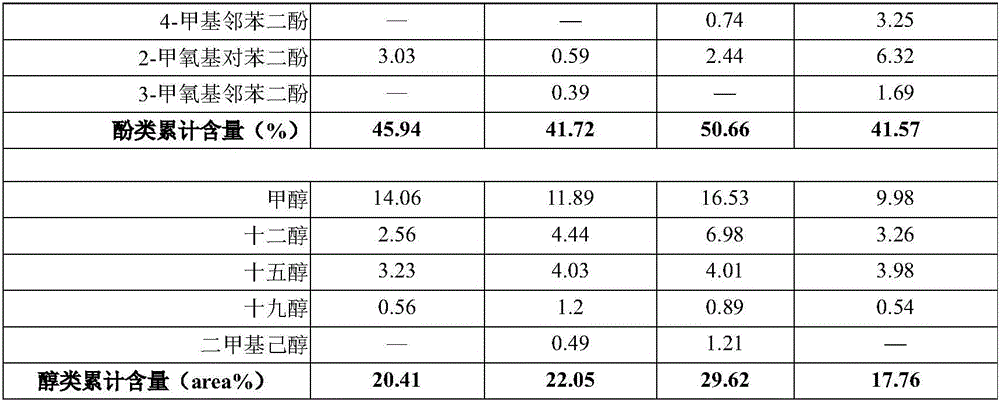

Examples

Embodiment 1

[0039] Be that the larch sawdust (moisture content 10%) of 0.1mm~0.45mm with particle diameter, the industrial silicon carbide that particle diameter is 10 μm~100 μm is an example to introduce the implementation process of the present invention as follows:

[0040] React 1 mole of industrial silicon carbide particles with 5 moles of chlorine gas at 1000°C for 2 hours to obtain modified silicon carbide. Dissolve 10g of nickel nitrate in 50g of absolute ethanol, then add 10g of modified silicon carbide, stir continuously for 30 minutes, seal and let stand for 12 hours, evaporate to dryness in a water bath at 50°C, and then place the evaporated solid in Calcining at 600° C. for 6 hours under an air atmosphere to obtain a nickel oxide supported catalyst. Dissolve 10g of palladium chloride in 50g of absolute ethanol, then add 10g of modified silicon carbide, stir continuously for 30 minutes, seal and let stand for 12 hours, evaporate the absolute ethanol to dryness in a 50°C water ...

Embodiment 2

[0042] Be that the corn stalk (moisture content 8%) of 0.45mm~0.9mm with particle diameter, the nano-silicon carbide that particle diameter is 100 μm~200 μm is an example to introduce the implementation process of the present invention as follows:

[0043] React 1 mole of nano-silicon carbide with 0.2 mole of hydrogen fluoride at 1200° C. for 1.5 hours to obtain modified silicon carbide. Dissolve 10g of ferric nitrate in 50g of absolute ethanol, then add 12g of modified silicon carbide, stir continuously for 45 minutes, seal and let stand for 20 hours, evaporate to dryness in a water bath at 55°C, and then place the evaporated solid in Calcining at 650° C. for 4 hours under an air atmosphere to obtain an iron oxide-supported catalyst. Dissolve 10g of ruthenium chloride in 50g of absolute ethanol, then add 12g of modified silicon carbide, stir continuously for 40 minutes, seal and let stand for 15 hours, evaporate the absolute ethanol to dryness in a 70°C water bath, and then d...

Embodiment 3

[0045] Be that 0.9mm~1.2mm wheat straw (moisture content 6%), particle diameter be 250 μ m~350 μ m α-silicon carbide as an example to introduce the implementation process of the present invention as follows with particle diameter:

[0046] 1 mole of α-silicon carbide was reacted with 3 moles of ammonium bromide at 1800° C. for 0.5 hour to obtain modified silicon carbide. Dissolve 10g of calcium nitrate in 50g of absolute ethanol, then add 50g of modified silicon carbide, stir continuously for 60 minutes, seal and let stand for 24 hours, evaporate to dryness in a water bath at 70°C, and then place the evaporated solid in Calcined at 800° C. for 3.5 hours in an air atmosphere to obtain a calcium oxide-supported catalyst. Dissolve 10g of rhodium chloride in 50g of absolute ethanol, then add 50g of modified silicon carbide, stir continuously for 60 minutes, seal and let stand for 24 hours, evaporate the absolute ethanol to dryness in a 70°C water bath, and then evaporate the evapo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com