Method for preparing hydrocarbon type oil and hydrochloric acid through pyrolytic-catalytic plastic and device

A hydrocarbon oil and pyrolysis technology, which is applied in the preparation of chlorides, the petroleum industry, chlorine/hydrogen chloride, etc., can solve the problems of insufficient heat in the kettle, affect pyrolysis, increase heat transfer resistance, etc., and reduce production costs , increased pyrolysis, and high removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

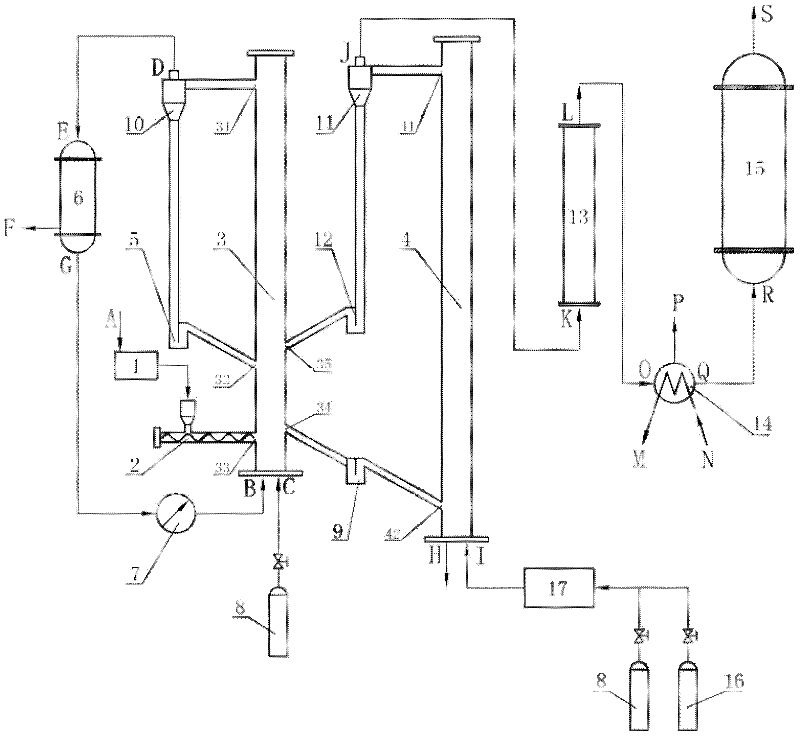

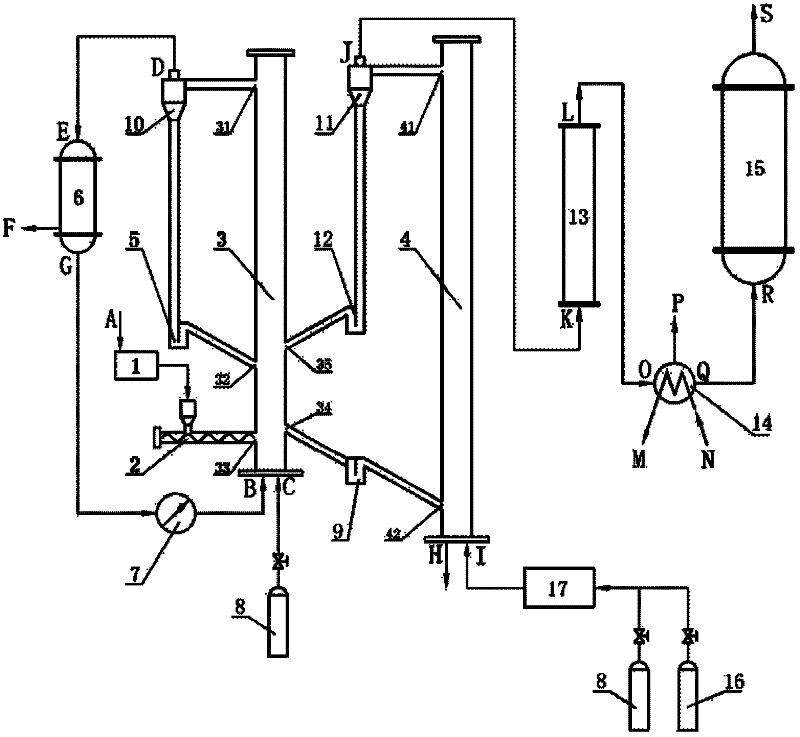

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The reaction device used in the method of the present invention is described in the invention patent "A method for producing hydrogen based on coal gasification and separating CO 2 The method and device thereof" (Patent No.: CN201010172522, hereinafter referred to as the patent) is mainly composed of two parts: a regenerative reactor system and a mixed gasification reactor system. This patent is used to produce hydrogen from coal gasification , the use of variable cross-section pipes is beneficial to the lifting and purification of hydrogen-rich gas, but if it is used in plastic pyrolysis reactions, the pipes will be easily blocked by plastic pyrolysis products because the diameter of the fluidized bed riser is small. The device used in the present invention is as figure 1 As shown, the two variable cross-section fluidized beds in the patent are changed into a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com