Device for producing ammonia gas through pyrolysis of urea by using high-temperature flue gas as heat source

A technology of high-temperature flue gas and urea, which is applied in the field of urea-ammonia production process, can solve the problems of large energy consumption and achieve the effects of high equipment integration, reduced dust content, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

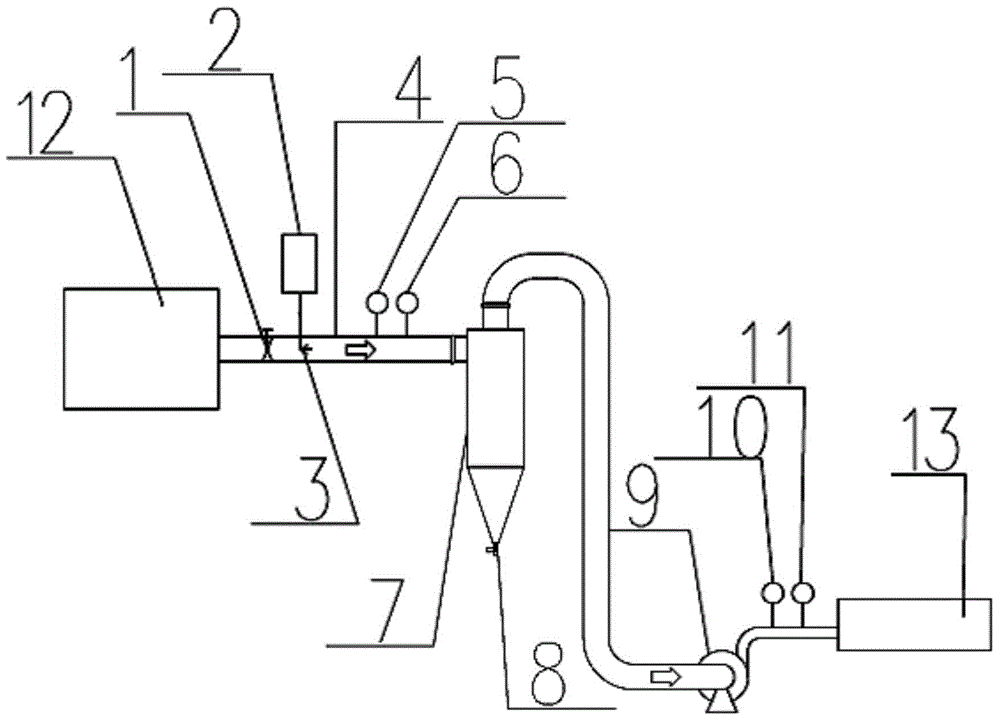

[0024] Such as figure 1 Shown is a urea pyrolysis ammonia production device using high-temperature flue gas as a heat source, using a swirling flow pyrolysis furnace 7 as a reactor for pyrolysis of urea and a mixer fully mixed with a dilution medium (flue gas). This kind of urea pyrolysis ammonia production device using high-temperature flue gas as a heat source includes a swirl pyrolysis furnace 7, a bypass flue 4, a flue gas baffle 1, a urea metering device 2, a mechanical atomization spray gun 3, and a flue gas flow rate Sensor 5, flue gas temperature sensor 6, booster fan 9, ash discharge hopper 8, pressure sensor 10 and temperature sensor 11.

[0025] One side of the swirling flow pyrolysis furnace 7 communicates with one end of the bypass flue 4, and the other end of the bypass flue 4 is provided with two inlets, which are the high-temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com