Preparation method and application of chitosan and/or metal composite of chitosan derivative

A technology of chitosan derivatives and metal complexes, which is applied in the direction of drug combinations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems that have not been reported in the application, and achieve low metal content , reduce the effect of toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] A chitosan zinc, silver, bismuth and rare earth metal cerium complex, the preparation method steps are as follows:

[0044] (1) 10g chitosan is ground into fine powder;

[0045] (2) 0.005g zinc nitrate, 0.005g bismuth nitrate, 0.005g silver nitrate, 0.005g cerium nitrate are ground into fine powder;

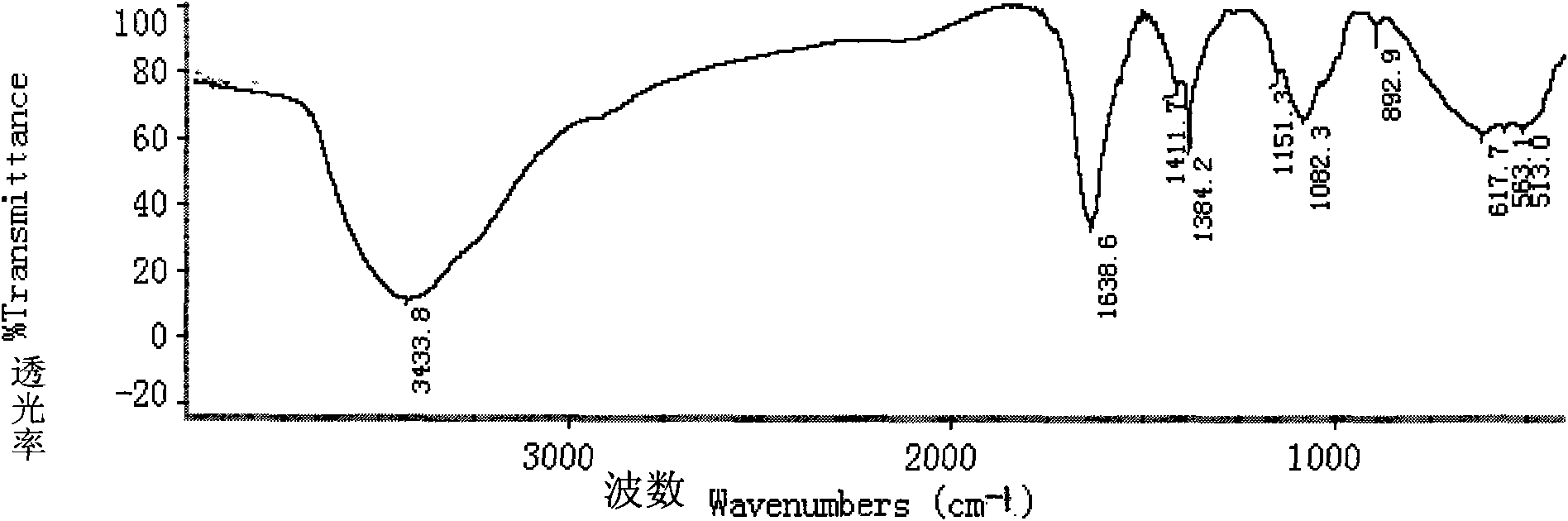

[0046] (3) Mix the chitosan fine powder with the fine powder obtained in step (2), and thoroughly grind for 3 hours to obtain the chitosan zinc, silver, bismuth and rare earth metal cerium complex (sample 1).

Embodiment 2

[0048] A chitosan silver, bismuth and rare earth metal cerium, lanthanum complex, the preparation method steps are as follows:

[0049] (1) 10g chitosan is ground into fine powder;

[0050] (2) 0.005g zinc nitrate, 0.005g bismuth nitrate, 0.005g silver nitrate, 0.005g cerium nitrate, 0.005g lanthanum nitrate are ground into fine powder;

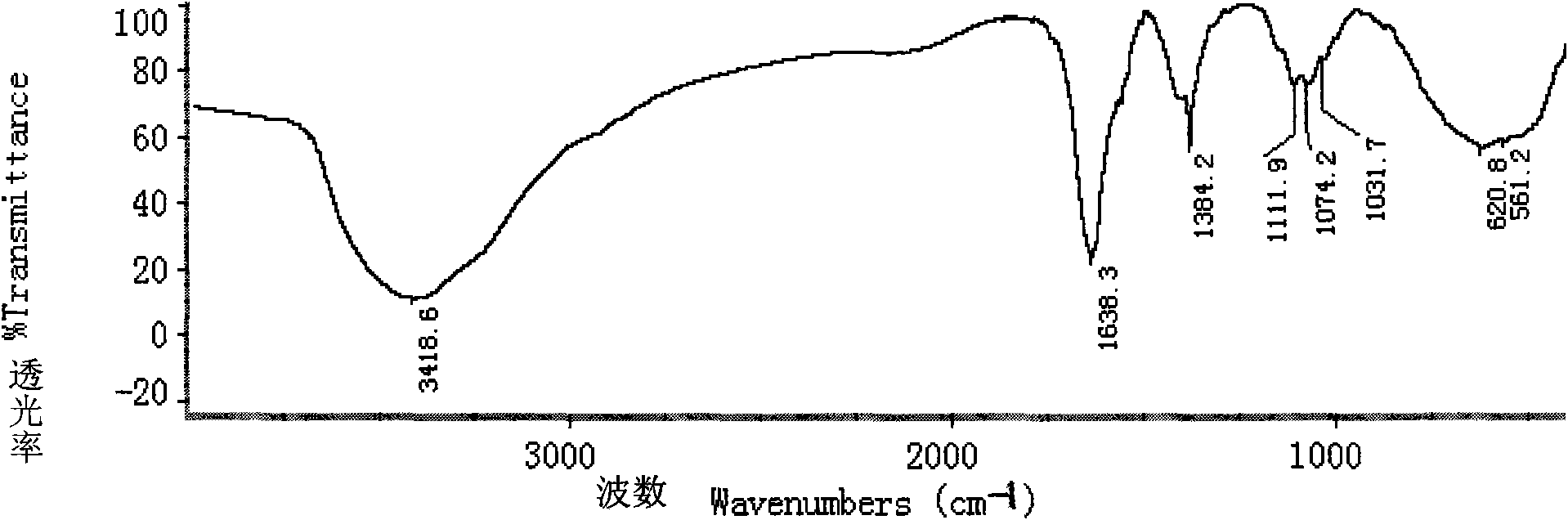

[0051] (3) Mix the fine powder of chitosan with the fine powder obtained in step (2), and thoroughly grind for 4.5 hours to obtain the complex of chitosan zinc, silver, bismuth and rare earth metal cerium and lanthanum (sample 2).

Embodiment 3

[0053] A chitosan zinc, silver, bismuth and rare earth metal cerium, lanthanum, rubidium, samarium complex, the preparation method steps are as follows:

[0054] (1) Grinding 5g of succinyl chitin into fine powder;

[0055] (2) Grinding each 0.01 g of zinc nitrate, bismuth nitrate, silver nitrate, cerium nitrate, lanthanum nitrate, rubidium nitrate, rubidium oxide, samarium nitrate, and samarium oxide into fine powder;

[0056] (3) Mix the succinyl chitin fine powder with the fine powder obtained in step (2), and fully grind for 6 hours;

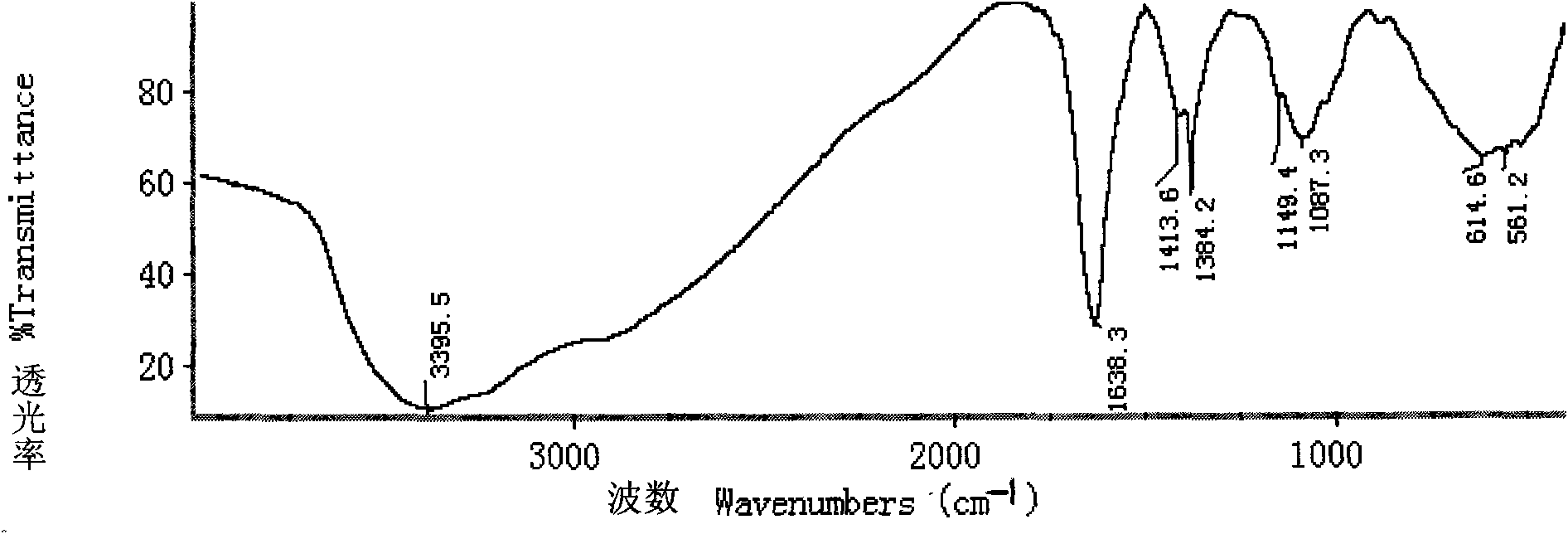

[0057] That is, succinyl chitin zinc, silver, bismuth and rare earth metals cerium, lanthanum, rubidium, samarium complex (sample 3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com