Ball valve with integrated removable flow venturi, flow balancing means, and pipe union means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

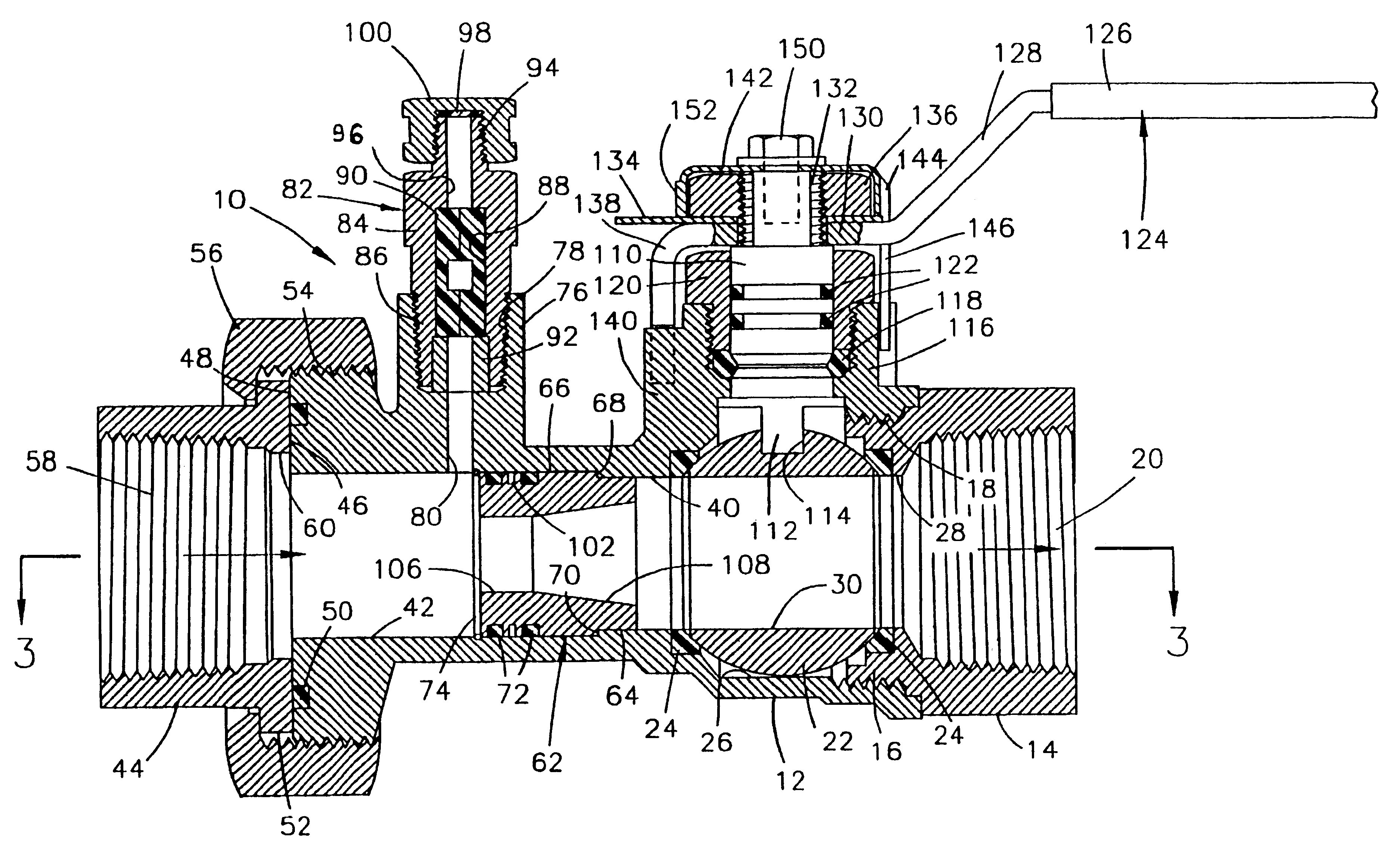

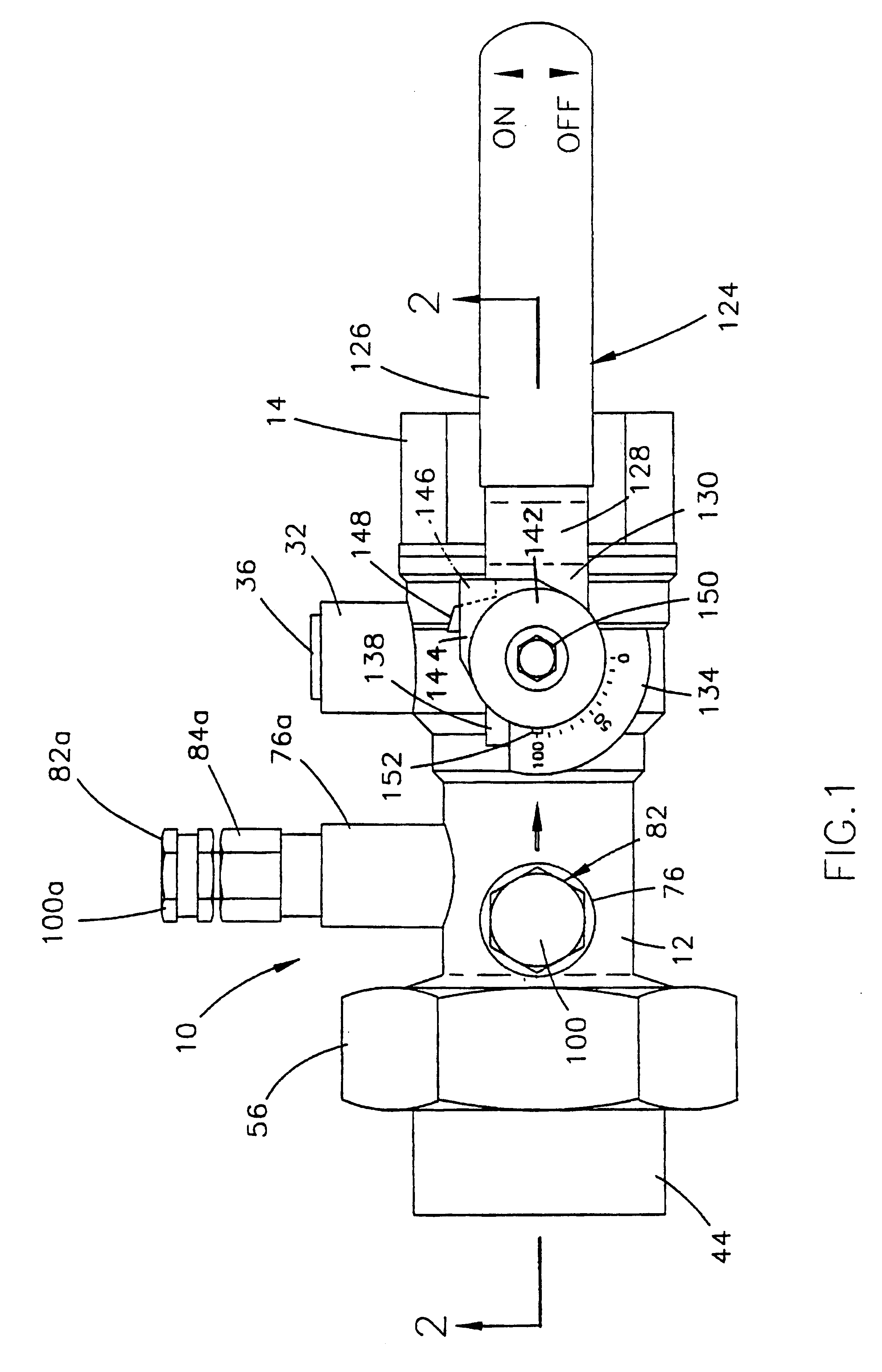

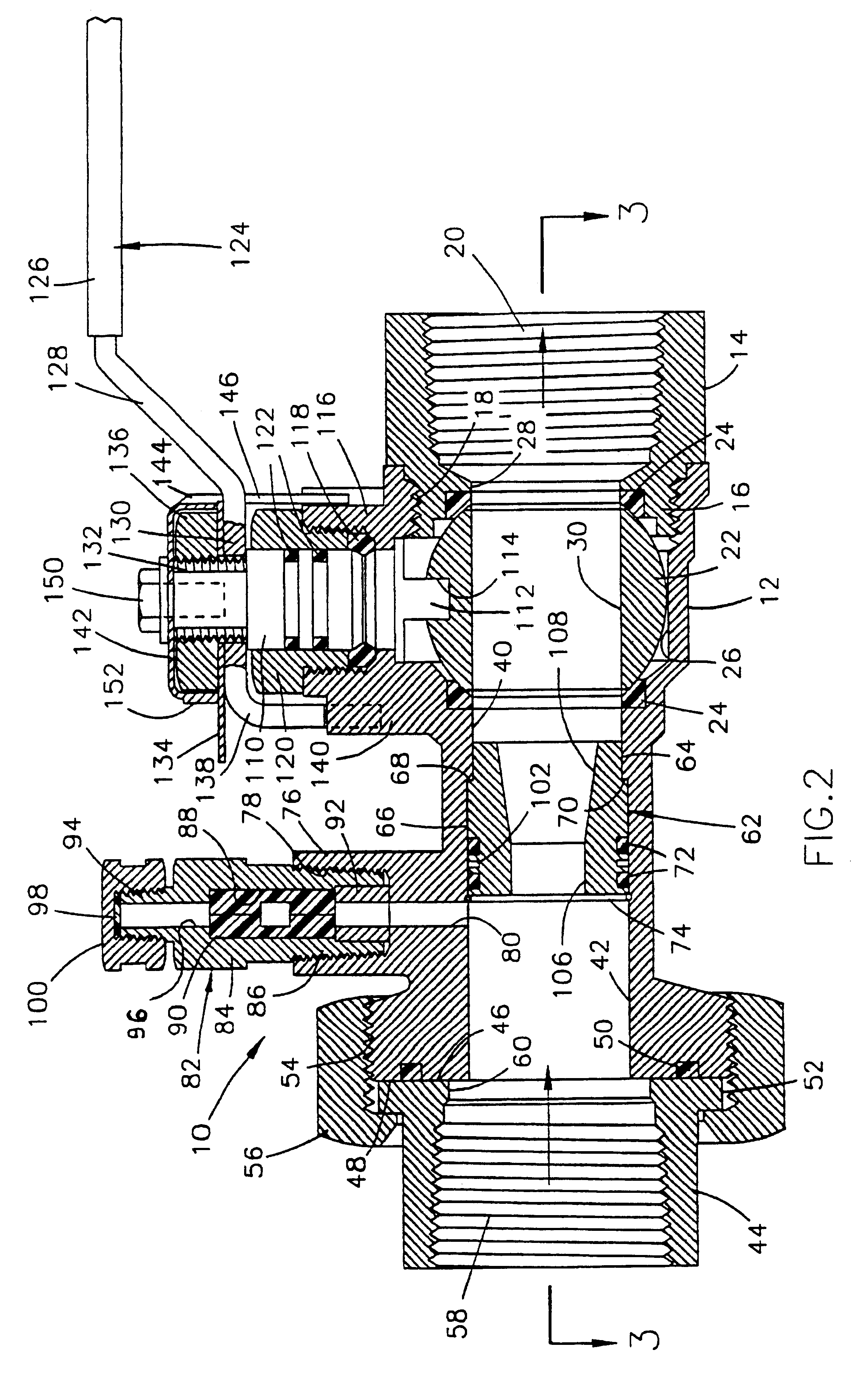

Referring now to the drawings, and in particular to FIGS. 1 and 2, the numeral 10 generally designates a ball valve assembly including a integrated removable venturi, a flow balancing means, and a pipe union means. The integrated ball valve assembly 10 comprises a valve body 12 that is provided on the exit end thereof with a valve body nut 14. The inner end of the valve body nut 14 is circular in shape and is provided with a peripheral threaded portion 16. The peripheral threaded inner end 16 of the valve body nut 14 is threadably mounted in the internally threaded valve body outlet end 18 of the valve body 12. The valve body nut 14 is provided with a threaded outlet port 20. A flow control quarter-turn ball valve 22 is rotatably mounted in a ball valve chamber 26 in the valve body 12 on a pair of ball seals 24. The flow control quarter-turn ball valve 22 is rotatably mounted about an axis perpendicular to the longitudinal axis of the valve body 12. The valve body nut 14 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com